THE ADVANTAGES OF USING COMBO CHASSIS IN TRANSPORTATION

The combo chassis is one of the common types of container chassis and offers a powerful combination of versatility, cost-savings, and efficiency for transporting various cargo types. In this article, Thaco Trailers will highlight the unique features and advantages of using combo chassis in transportation.

1. What is a combo chassis? Learn about types and uses

1.1 What is a Combo Chassis?

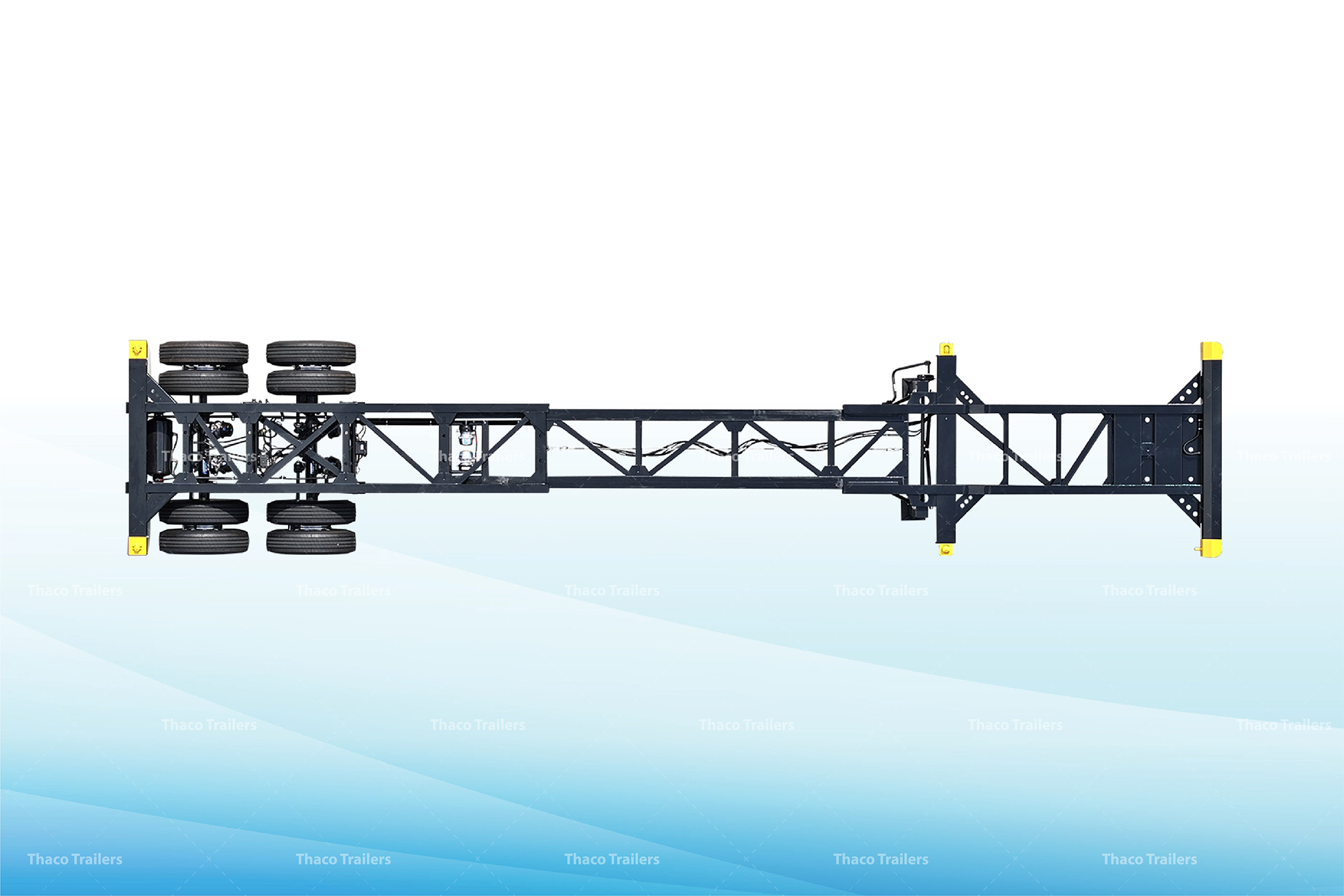

A combo chassis is a multi-purpose trailer designed for efficient transportation of diverse cargo. It is engineered to carry both 20ft and 40ft sized containers when loaded, or two 20ft containers simultaneously when empty. This adaptability makes it an ideal choice for businesses involved in frequent empty container logistics, ensuring efficient and cost-effective operation.

Read more: Understanding Chassis and Trailers: A Comprehensive guide

1.2 Types of Combo Chassis

- Standard 20’/40’ Combo Chassis: Designed for general cargo transport and long-hauls, and is compatible with most ISO container types. Thaco Trailers’ standard combo chassis is configured with a 109-inch spread dual axles setup, designed to enhance stability and weight distribution. This enhanced stability makes the standard combo chassis the perfect configuration for long-haul transportation.

- 20’/40’ City Combo Chassis: Thaco Trailers’ specialized variant with a tandem axles configuration, often referred to as the 20’/40′ City Combo Tandem, is ideal for urban environments where maneuverability is crucial, provided with the compact wheelbase, enhancing the turning radius. The reduced size also results in lower tare weight, and therefore increasing payload capacity, carrying up to 67,200 lbs in the extended 40’ container configuration.

- Other Combo Chassis Configurations: The combo chassis is one of the most versatile types of container chassis, as the market offers various configurations, suitable for different transportation demands. Some providers also offer combo chassis of up to 4 different length set-ups, such as 20’/40’/45’ combo chassis, or 20’/40’/45’/53’ combo chassis, with different axle configurations, from tandem and tridem set-ups, to spread axle, 4-axle, and 5-axle, each suitable for different purposes, from long-hauls to urban maneuverability.

1.3 Practical Applications of Combo Chassis

- Streamlining intermodal operations for efficient cargo movement: Coordination between distinct transportation systems like railroad, sea, etc so that a single integrated system is provided to the consumers.

- Urban Delivery: Especially for the short and overall small wheel-base city combo chassis, the maneuvering ability in a more congested city street or loading /unloading zone will be easier and that will enable the city combo chassis to deliver its container efficiently within the crowded urban centers; lastly it has flexibility in the type /size of container allowed.

2. The Key Advantages of Combo Chassis

2.1 Versatility Across Multiple Cargo Types

Combo chassis are known for their versatility, accommodating many cargo types. For example, the 20’/40′ City Combo Tandem of Thaco Trailers is engineered for flexibility and strength and allows operators to transport both 20’ and 40’ containers with ease. This flexibility reduces the need for multiple chassis, simplifying fleet management and reducing costs.

Read more: Reputable semi-trailer manufacturers

2.2 Cost-Effective Transportation Solutions

One of the primary benefits of using a combo chassis is cost-effectiveness. They will thus be able to reduce many operating expenses, and reduce or avoid having many fleets on the road while at the same time helping to manage resources through promoting the transport of containers of different sizes on a single chassis. This efficiency will indeed lead to a lot of savings in the long run.

Read more: Intermodal transport: definition & differences from multimodal transport

2.3 Streamlined Intermodal Transport

This system also termed as seamless intermodal logistics is a trucking system where goods and shipments are moved from a prescribed location to another without touching by anyone in between. This system uses standardized transport containers that are also suitable for trucks, trains, and ships, which provide the means of changing from one mode of transport to the other. Regarding this, it will be seen that Combo chassis are perfect for intermodal transport because of their versatility with the type of load they can carry and the equipment used to handle it.

Read more: What is an Intermodal Chassis in Logistics?

2.4 Compliance with Regulatory Standards

The chassis can also contain features for safety reasons to meet road laws and gain better lightness. These could be lights, reflectors and breaks. Regulatory requirements and guidelines are another measures which have to be met for the exercise of safe transportation and averting cases of legal violations.

Thaco Trailers’ combo chassis are built to meet international safety and quality standards, providing operators with confidence that their cargo is being transported safely and legally. This compliance not only helps avoid potential fines but also ensures smooth operations and provides peace of mind with exceptional safety features such as Anti-lock Braking Systems (ABS), Electronic Stability Control (ESC), Tire Pressure Monitoring Systems (TPMS), as well as accident avoidance measures such as underride guards.

Read more: Top Container Chassis Manufacturer Exporter to The US

3. Choosing the Right Combo Chassis for Your Needs

Selecting which type of container chassis is best for your needs can be a powerful decision because it determines how effective, inexpensive, and secure your transportation is. The above options would make it easier to have different factors that when examined would enable one to choose the right chassis for the business. Thaco Trailers will explain the 4 requirements to look at when selecting the chassis for intermodal transportation.

3.1 Cargo Type and Requirements

When selecting the best container chassis, there is one thing that concerns the user more, and that is the type of goods to be transported. Many types of cargo have prescribed weights, dimensions, and safety features that must be complied with by shippers and carriers.

- Payload Capacity: Ensure that the chassis will support your cargo hence not be a danger to the passengers and befitting for traffic.

- Size and Dimensions: Choose a chassis that can accommodate your container’s length, width, and or height. Also, choose the right chassis with increased payload and stability features to meet your requirements.

- Special Requirements: Consider if your cargo has specific needs, such as temperature control or hazardous material transport. Additionally, select a chassis that conforms with additional applicable safety regulations regarding transporting potentially hazardous goods to ensure legal transportation of such freights.

3.2 Dimension

- Length: The chassis must accommodate to support the length of the containers being transported. For example, a combo chassis designed to handle both 20ft and 40ft containers offers increased flexibility for various shipping needs.

- Width and Height: The width and height of the chassis must adhere to transportation regulations and be suitable for the physical constraints of the routes, such as narrow roads in urban areas. Choosing the right dimensions ensures smooth transit through these environments.

- Payload Capacity: The weight capacity of the chassis refers to the maximum load it can carry safely. It’s essential to choose a chassis that can handle the weight of the cargo and container combined. For instance, a chassis with a higher weight capacity will allow the transport of heavier goods without straining the structure, which helps maintain stability and ensures compliance with transport safety standards.

Read more: How to choose the right gooseneck container trailer?

3.3 Budget

The selection of the ideal container chassis is influenced greatly by financial considerations. But it’s crucial to balance price, utility, and quality.

- Initial Cost: Compare the upfront costs of different chassis options.

- Total Cost of Ownership: Consider all long-term expenses, such as possible repairs, fuel economy, and routine maintenance.

- Return on Investment: Assess the chassis’s potential effects on your business’s profitability and operational effectiveness.

- Although it may be tempting to choose the least expensive alternative, think about the total cost of ownership and invest in a chassis that will provide the best value throughout its useful life.

4. Maintenance and Operational Tips

Maintaining container chassis properly is essential to guarantee the effective and secure transportation of cargo. Frequent maintenance can assist extend the lifespan of the chassis, minimize downtime, and help avoid malfunctions. The following fundamentals of container chassis upkeep and operating advice will be addressed by Thaco Trailers:

4.1 Clean the Chassis

In addition to keeping the container chassis clean, cleaning also stops rust and other forms of corrosion. To clean the chassis, use a gentle soap and water solution; do not use strong chemicals that might harm the paint or other parts.

4.2 Preventative Maintenance

Potential problems can be identified and remedied before they become expensive ones by putting preventative maintenance into place. The essential parts of the container chassis, such as the tires, suspension, brakes, and lighting, should all be covered by a maintenance program for preventative maintenance. The container chassis must also be inspected regularly to spot possible faults before they become safety hazards. Any indications of wear or damage, especially to the essential parts as mentioned, need to be fixed right away to ensure the safe operation of the vehicle.

Read more: The ultimate guide to selecting tri-axle chassis for semi-trailer

4.3 Lubricate Moving Parts

Lubricating moving components could prevent wear and tear and increase the lifespan of the chassis, including the landing gear, fifth wheel, and suspension. Apply the lubricant according to the manufacturer’s instructions and use a high-quality product.

4.4 Replace Tires

Tires are important parts of the container chassis and should be checked and changed regularly. Verify the tread wear, tire pressure, and sidewalls for any indications of deterioration. Replace any worn-out, damaged, or older than six-year-old tires.

5. Thaco Trailers’s Combo Chassis

Thaco Trailers offers a variety of combo chassis types designed to meet the diverse needs of the transportation industry. Thaco Trailers’s products are distinguished by their numerous advantages, such as:

- Low tare weight, high payload capacity

- Superior durability

- Flexible configurations to handle various cargo types

- Compliance with international standards

- Outstanding additional safety features

Below is the list of the Thaco Trailer’s combo chassis:

20’/40′ Combo Tandem

20’/40′ Combo Tridem

20’/40′ City Combo Tandem

20’/40’/45′ City Combo Tridem Without Genset

20’/40’/45′ City Combo Tridem With Genset

Thaco Trailers is Vietnam’s largest semi-trailer manufacturer and supplier, utilizing advanced technologies such as fiber laser cutting, CNC brake presses, and robotic welding, and always keen to adopt the latest innovations. Thaco Trailers’ products meet international standards, primarily those required in North American markets, including DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA. Aiming at maintaining the high quality and safe performance of their products, Thaco Trailers consistently conducts rigorous testing, including sideslip, brake, road, and load tests.

Among its versatile offerings, Thaco Trailers’ combo chassis provides an ideal solution for transportation companies looking for flexibility and cost efficiency for their fleets. With their ability to adapt to a range of container sizes and cargo types, combined with multiple configurations suitable for different intended uses, Thaco Trailers’ combo chassis offers enhanced intermodal capabilities, optimizing operations across varied transportation networks. Thaco Trailers’ combo chassis, designed to meet stringent international standards, stands out as a top-tier choice for businesses seeking reliable and efficient transportation solutions.

Read more: What is a Genset Chassis? Application and How it works

Visit Thaco Trailers today to explore our range of combo chassis and discover how they can elevate your logistics operation. Regardless if you are in the market for light and medium duty or looking to upgrade your operation’s efficiency our combo chassis has got the capabilities your company needs. Call us today or check out the products that may fit the needs for your transportation needs.

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn