A COMPREHENSIVE GUIDE TO TRAILER SUSPENSION SYSTEMS

Understanding the intricacies of trailer suspension systems is crucial for ensuring optimal performance, safety, and cargo protection. In this comprehensive guide, Thaco Trailers will provide the insights needed to choose the right suspension system, tailored to meet the demands of different loads, terrains, and operational needs.

1. What is a trailer suspension system?

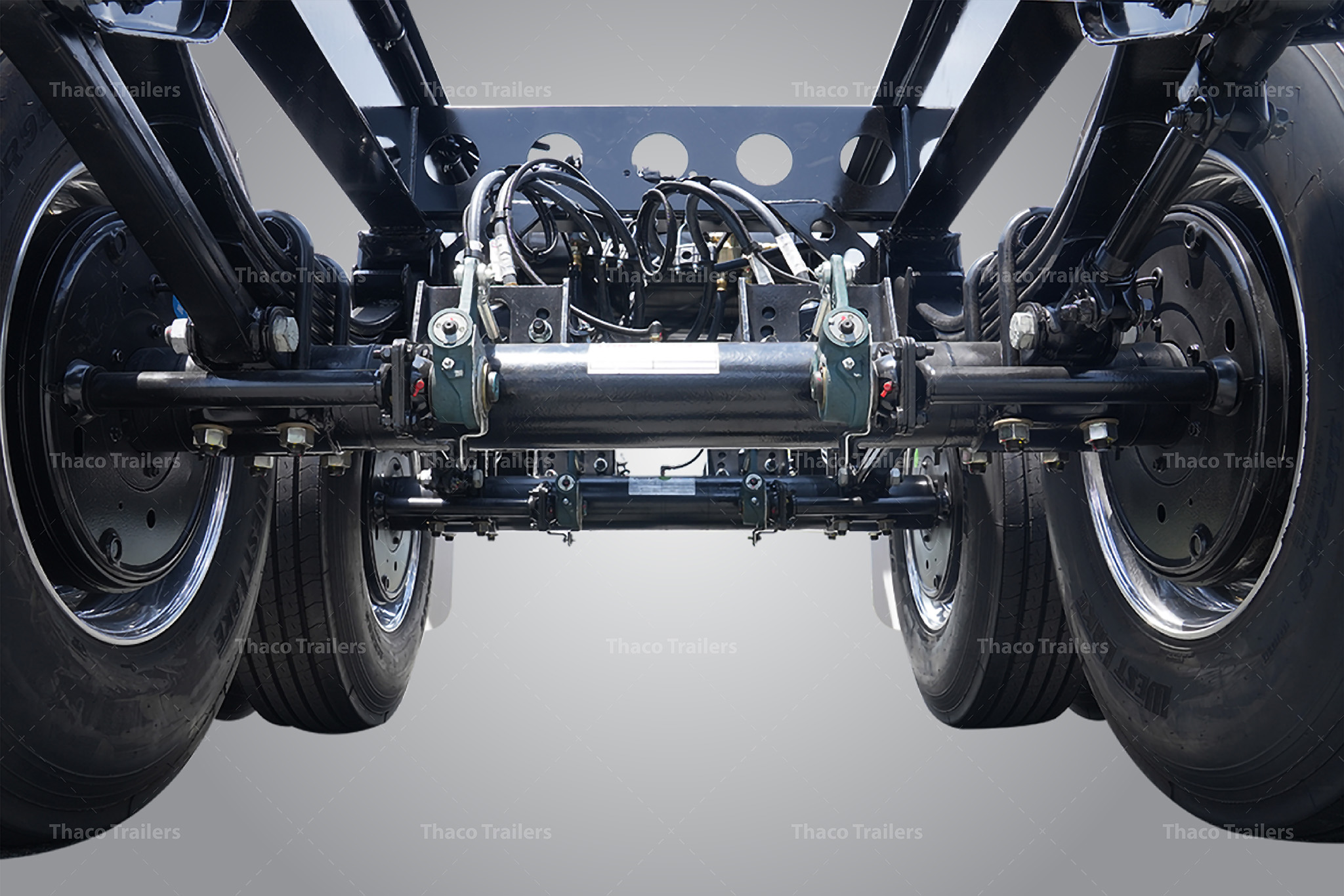

A trailer suspension system is the critical part between the trailer’s frame and its wheels. Its key components include axles, springs, shock absorbers, linkages, and bushings – all interlinked for seamless road travel and stability. Its purpose is to absorb most of the shocks transmitted through the road for cushioning. This allows the trailer to move without excessive bounce or swaying in rough terrain and bumpy surfaces.

A trailer suspension system ensures even weight distribution over the tires, maintaining optimal contact with the road for stability and control. It minimizes wear on both the trailer and its tires while safeguarding the cargo. Proper understanding of the system is crucial for making informed decisions on maintenance, repairs, and upgrades to maintain roadworthiness and efficiency.

>>Read more: what are the different types of semi-trailers?

2. The importance of the suspension system in trailer

There are a couple of advantages that come with good suspension. Firstly, the friction between the tires and the road is maximized by the suspension so that the trailer maintains its traction and remains stable on sharp turns or sudden stops, especially on rough roads or with heavy loads.

The system absorbs vibrations from bumps, potholes, and uneven surfaces, preventing heavy bouncing or swaying, resulting in a smoother trip and reducing long-term maintenance stress on the trailer components.

Additionally, an effective suspension system ensures even weight distribution, thereby reducing tire wear and extending tire lifespan. Installing a new heavy-duty suspension for the trailer designed to carry heavy cargo will improve its load-carrying capability and performance. More importantly, a good suspension system enhances safety by improving driver control and reducing unnecessary risks.

The choice of a suitable suspension system depends on transportation needs and the terrains frequently traversed. For heavy-duty trailers advanced systems such as air suspensions may be needed in operation under what could otherwise be described as high-stress conditions, while lighter trailers may be adequately served by much simpler options such as torsion axles or leaf springs. Whichever suspension type is fitted to a trailer, a good suspension system contributes a lot to cargo safety and efficiency in the journey.

>> Read more: essential components of trailer suspension systems

3. Exploring the different types of suspension systems on trailer

Trailer suspension systems come in various forms, each tailored to meet specific transport needs. Choosing the right suspension system is essential for optimizing performance, improving cargo safety, and ensuring a smooth ride.

3.1 Leaf spring suspension

Leaf spring suspension is one of the oldest systems in use, known for its simplicity and durability. It is cost-effective, making it a practical choice for those seeking an affordable yet reliable suspension solution.

Moreover, the straightforward design allows for easy maintenance, as individual leaf springs can be replaced when they wear out. These systems are particularly effective for carrying heavy loads, providing consistent performance for commercial trailers.

However, leaf spring suspensions can deliver a stiffer ride, particularly on rough or uneven roads, compared to more advanced systems. Over time, the metal components may develop noise and show signs of wear, requiring regular inspection. While they perform well on smooth roads, their shock absorption is limited, making them less suitable for particularly rough terrains.

3.2 Torsion axle suspension

Torsion axle suspension offers a smoother ride than traditional leaf springs, thanks to its independent wheel movement. This design reduces bounce and enhances stability, making it ideal for smaller trailers carrying light loads. Torsion suspensions also require minimal maintenance compared to other systems, which is a significant advantage for trailer owners seeking reduced upkeep.

On the downside, torsion axle suspensions come with higher initial costs, making them a more expensive option than leaf springs. Their weight-carrying capacity is also limited, which means they are not the best choice for trailers designed to haul heavy cargo. Despite their superior ride quality, their application is restricted to lighter, less demanding transport scenarios.

3.3 Independent suspension

Independent suspension systems are known for providing exceptional ride comfort, as each wheel operates independently, adjusting to uneven terrain. This system greatly enhances stability and traction, reducing trailer sway and improving safer handling, especially on challenging roads, making it particularly beneficial for premium trailers like semi-trailers. However, the complexity of these systems leads to higher operational and maintenance costs, with repairs often being more intricate and requiring specialized tools and expertise, making independent suspensions a greater investment overall.

3.4 Air suspension

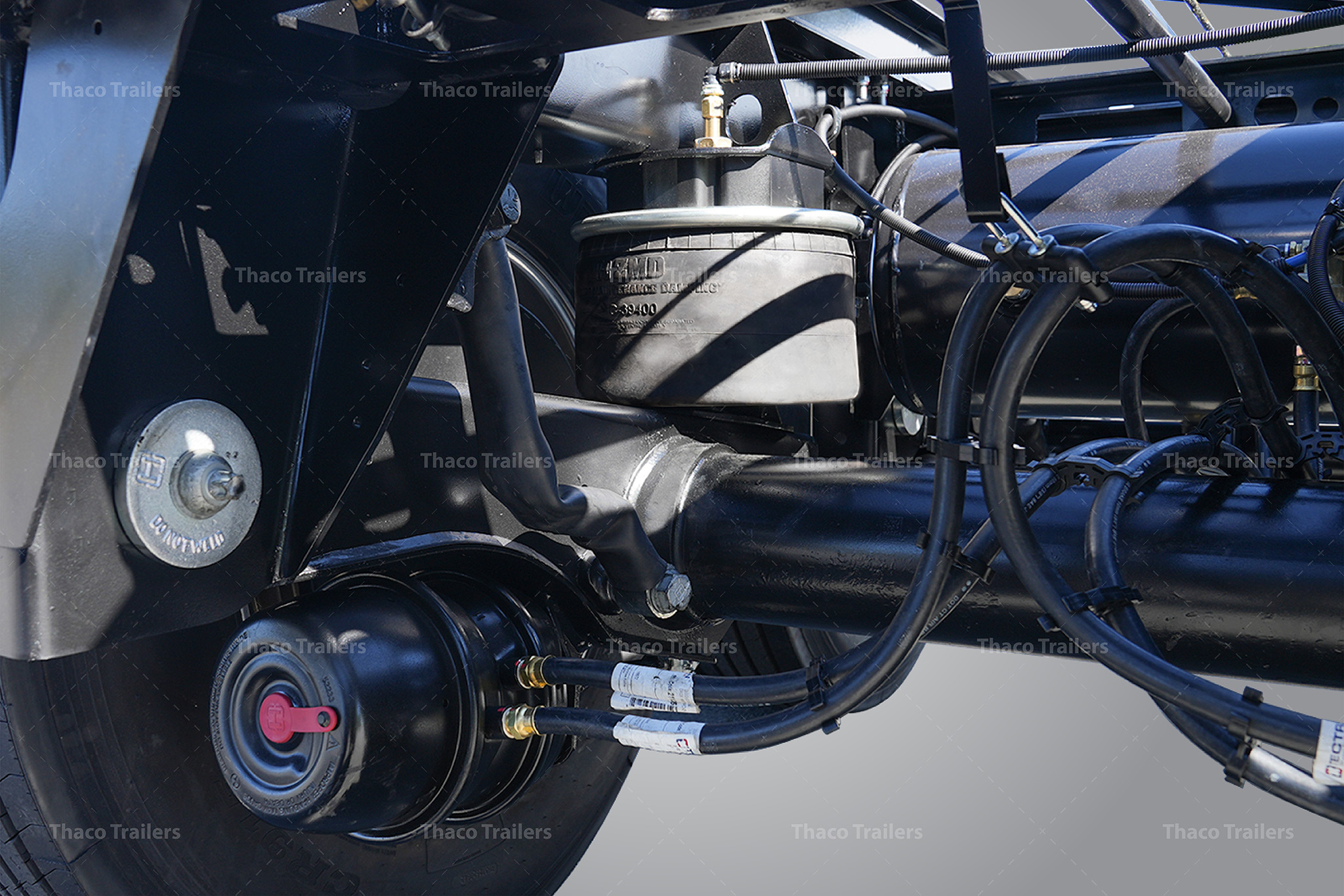

An air suspension system on a trailer uses air springs instead of traditional steel springs, providing a smoother and more adjustable ride. Powered by an onboard air compressor, the system adjusts air pressure in the airbags to maintain a consistent ride height and distribute weight evenly across the axles, improving stability and comfort. Compared to leaf and coil spring systems, air suspension offers superior load management, better shock absorption, and enhanced safety, though it requires more maintenance and is costlier to install.

3.5 Rubber suspension

Rubber suspension systems are valued for their quiet operation and low maintenance requirements. They eliminate metal-to-metal contact, reducing noise and vibration, which makes them ideal for specialty trailers. The rubber components provide effective shock absorption, helping to protect delicate cargo from the impacts of road irregularities.

However, rubber suspensions have their limitations as they are not suitable for heavy loads, making them better suited for smaller trailers. Over time, the rubber elements can deteriorate and require replacement, adding to long-term maintenance costs. Although these systems perform well in specific applications, their limited weight capacity restricts their use in more demanding transport scenarios.

>> Read more: what is container chassis? learn about types and uses

4. The difference between trailer suspension system and semi-trailer suspension system

Although trailer and semi-trailer suspension systems share similarities in their purpose such as stabilizing loads, improving ride quality, and enhancing safety, they differ in structure, design, and application. Understanding these differences is essential for choosing the right suspension system based on the type of vehicle, load capacity, and intended usage.

4.1 Design and configuration

The suspensions of the trailers are directly fastened to the frame of the trailer, which carries all the load independently. The larger ones may have more than one axle for equal distribution of the weight and can be leaf springs, torsion bars, walking beams, or hydraulic suspensions to absorb the bumps for smooth travel on irregular surfaces. Such suspensions need to be very durable, especially for off-road or heavy-duty applications.

Semi-trailer suspension systems, on the other hand, are designed to operate in conjunction with a tractor unit: the front of the trailer sits on the tractor’s fifth wheel and carries part of the load onto its rear axles. This lessens the amount of axles actually needed on the trailer and is often integrated with leaf springs or air suspensions to keep it flexible and steady on the long haul. A configuration that also strengthens the turning capacity of the truck, allowing semi-trailers to execute smooth turns which makes them quite fitting for heavy and sizable loads’ transportation along highways.

4.2 Weight distribution and load handling

Trailer suspensions support the full weight of both the trailer and its cargo independently, requiring many heavy-duty trailers to have multiple axles for even weight distribution. Components like turntables and drawbars are often added to enhance articulation and maneuverability. Since trailers do not depend on towing vehicles for load distribution, their suspensions must be strong enough to manage varying load conditions on their own.

Semi-trailers share their load with the tractor unit, with the front resting on the tractor’s fifth wheel and transferring much of the weight to its rear axles. This interdependent design reduces the need for additional axles on the semi-trailer, simplifying maintenance and lowering costs. The load-sharing configuration also enhances maneuverability, allowing semi-trailers to navigate sharp turns and tight roads more easily than similarly sized trailers.

4.3 Suspension types and performance

Trailers use different suspension systems based on their purpose, including leaf spring, torsion axle, air, and rubber suspensions. Leaf springs are durable and affordable, torsion axles allow independent wheel movement, and air suspensions offer better ride quality with adjustability. Rubber suspensions are ideal for specialty uses, like livestock transport, due to their quiet operation and vibration reduction.

Semi-trailers typically use air suspensions for better shock absorption and cargo stability over long distances. These systems are favored for their ability to adjust the trailer’s height, streamlining loading and unloading. Leaf spring suspensions are also common for heavy loads, offering a dependable foundation, though the semi trailer’s design requires the suspension to support only part of the total load, simplifying its structure.

4.4 Maintenance and durability

Trailer suspensions are further complex and require regular maintenance; this is particularly true for multi-axle or hydraulic models. Trailers employed off-road or in heavy-duty applications are under higher stress and need to be inspected much more frequently, along with the replacement of parts, to continue to perform well over a long period. For instance, leaf springs, shock absorbers, and bushings will need constant checking to avoid failure while in transit.

By comparison, semi-trailer suspensions are less fiddly since they have fewer components; air suspensions require more attention, given how the airbag, valves, and compressors can leak or fail. Regular checks and timely repairs will keep them operating smoothly and ward off road calls on long hauls, thus helping give air suspensions a longer life expectancy by lessening stress on individual components.

>> Read more: top container chassis manufacturer exporter to the us

5. Choosing the right suspension systems for semi-trailers

Choosing the right suspension system for your semi-trailer is essential for ensuring safe, efficient, and comfortable transport. The right system affects not only how well the trailer performs but also how it handles different loads, road conditions, and terrain types.

5.1 Load capacity and weight distribution

The load-carrying capacity is the most important feature in your suspension. Semi-trailers usually carry very heavy cargo, so the suspension should be able to bear a massive amount of weight without compromising either the safety or stability of that weight. Air suspension systems are popular for heavy-duty applications since they manage the load distribution with pressure adjustment to match the weight of the cargo.

However, leaf springs suspensions also see their fair share of applications because they can be durable and resistant to heavy hitch loads over great distances. The selection of a system with sufficient load-carrying capacity ensures stability of the trailer while reducing any risks of sway or uneven tire wear.

5.2 Terrain and road conditions

The type of terrain your semi-trailer will encounter plays a significant role in selecting a suspension system. If your routes include highways or smooth urban roads, a torsion axle or leaf spring suspension may suffice, offering a balance between comfort and durability.

However, for trailers frequently traveling on rough or uneven terrain, an air suspension system provides better shock absorption and protects both the cargo and trailer components. Air suspensions also offer height adjustability, which can be crucial when navigating uneven surfaces or loading docks.

5.3 Ride quality and cargo protection

For sensitive or fragile cargo, ride quality becomes a top priority. A smooth ride reduces vibrations and jolts that can damage goods during transit. Independent suspension systems are excellent for improving ride quality, as each wheel moves independently, ensuring stability on uneven roads.

Similarly, air suspensions absorb shocks more effectively than traditional leaf springs, making them ideal for long-haul trips with delicate cargo. Choosing a suspension system that prioritizes comfort not only protects the cargo but also reduces driver fatigue, leading to safer journeys.

5.4 Maintenance and cost of ownership

Different suspension systems require varying levels of maintenance, which affects long-term operational costs. Air suspensions, while offering superior performance, require more frequent inspections and maintenance to prevent air leaks or component failures.

In contrast, leaf spring systems are simpler in design and easier to maintain, making them cost-effective for fleets with high usage. It’s also essential to consider the availability of spare parts and manufacturer support, as these factors influence the downtime and repair costs associated with each suspension type. Balancing initial costs with long-term maintenance needs ensures you get the best value from your suspension system.

5.5 Adjustability and versatility

Adjustability can be a crucial feature, particularly if your semi-trailer handles a variety of cargo types or travels across diverse terrains. Air suspension systems offer excellent versatility, allowing operators to adjust the ride height to match the load or road conditions. This adaptability improves safety and efficiency during loading and unloading operations.

Additionally, adjustable suspension helps maintain proper weight distribution. This reduces tire wear and enhances stability. If your operations demand frequent adjustments, an air suspension may be the ideal choice.

>> Read more: what is an intermodal chassis in logistics?

6. Thaco Trailers’ suspension systems: customized to meet your semi-trailer’s specific needs

Thaco Trailers has the capability to customize suspension systems for semi-trailers by utilizing a diverse range of leaf springs from the Thaco Springs brand Vietnam’s leading high-quality leaf spring manufacturer. Thaco Springs products are manufactured on advanced, highly automated production lines and undergo stringent quality control at every stage, adhering to JIS B 2710 standards. As a result, they offer superior quality, high elasticity, excellent load capacity, and enhanced stability for smooth operation across various terrains.

Additionally, based on customer requirements, Thaco integrates premium suspension systems from globally recognized suppliers such as HUTCH (USA) and STANDEN (Canada). Through expert design consultation tailored to specific business and market needs, Thaco Trailers ensures that each semi-trailer’s suspension system is optimized for operational performance, enhancing both durability and efficiency.

Understanding the different types of trailer suspension systems is essential for making informed decisions that enhance performance, safety, and cargo protection. Whether opting for the durability of leaf springs, the adjustability of air suspensions, or the stability of independent systems, choosing the right suspension ensures smoother rides and reliable operations. With Thaco Trailers offering customized solutions to meet specific needs, operators can confidently equip their trailers for any journey, ensuring long-term efficiency and peace of mind.

>> Read more: reputable semi-trailer manufacturer

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn