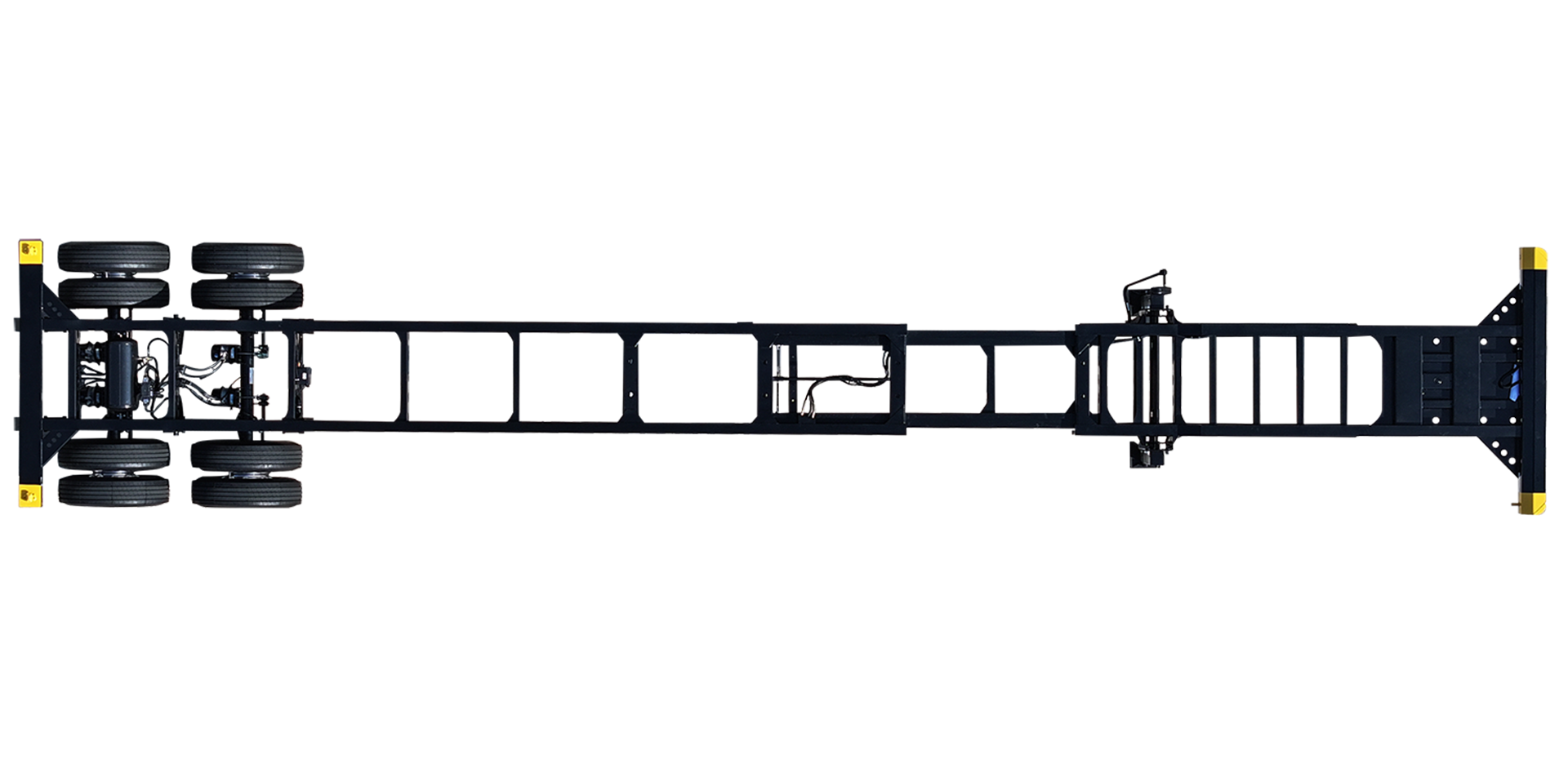

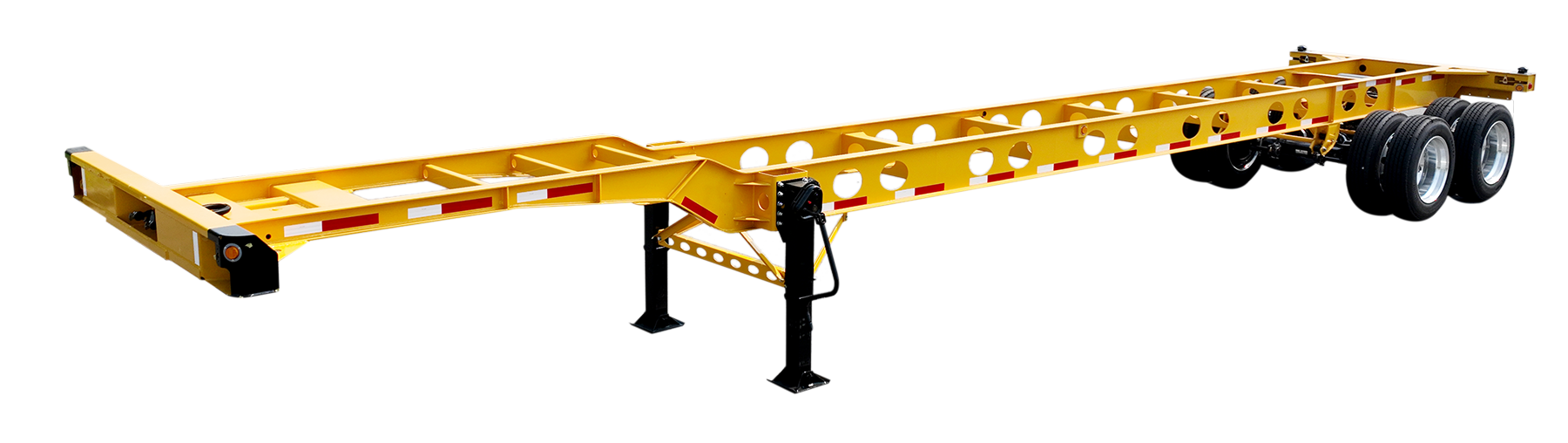

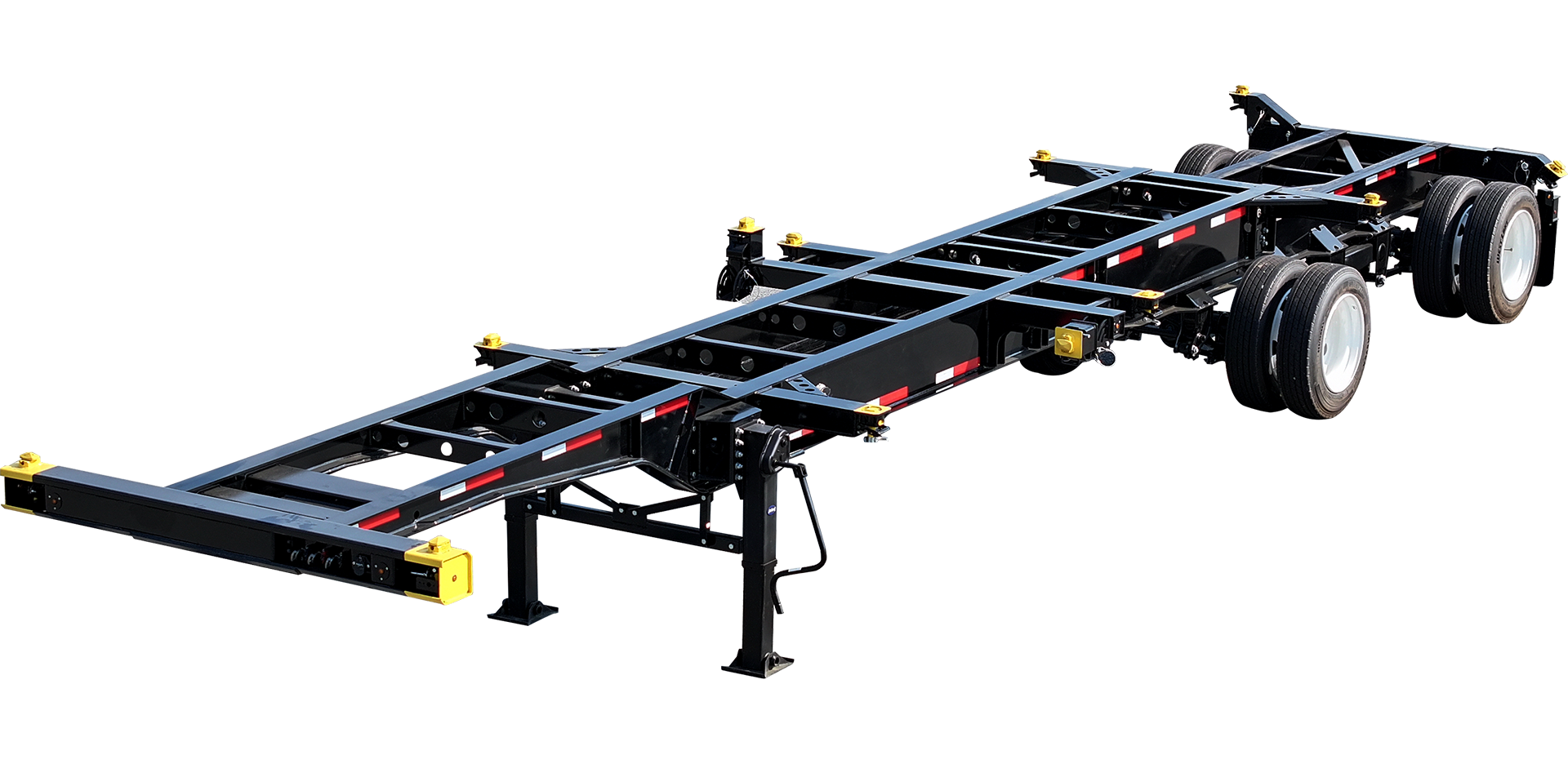

40’/45′ Extendable Tandem

Overall Length: 40’-11” retracted or 45’-11” extended

Overall Width: 96”

Overall Height: 58”

Fifth Wheel Height: 48 ± 1”

Rear Deck Height: 48 ± 1”

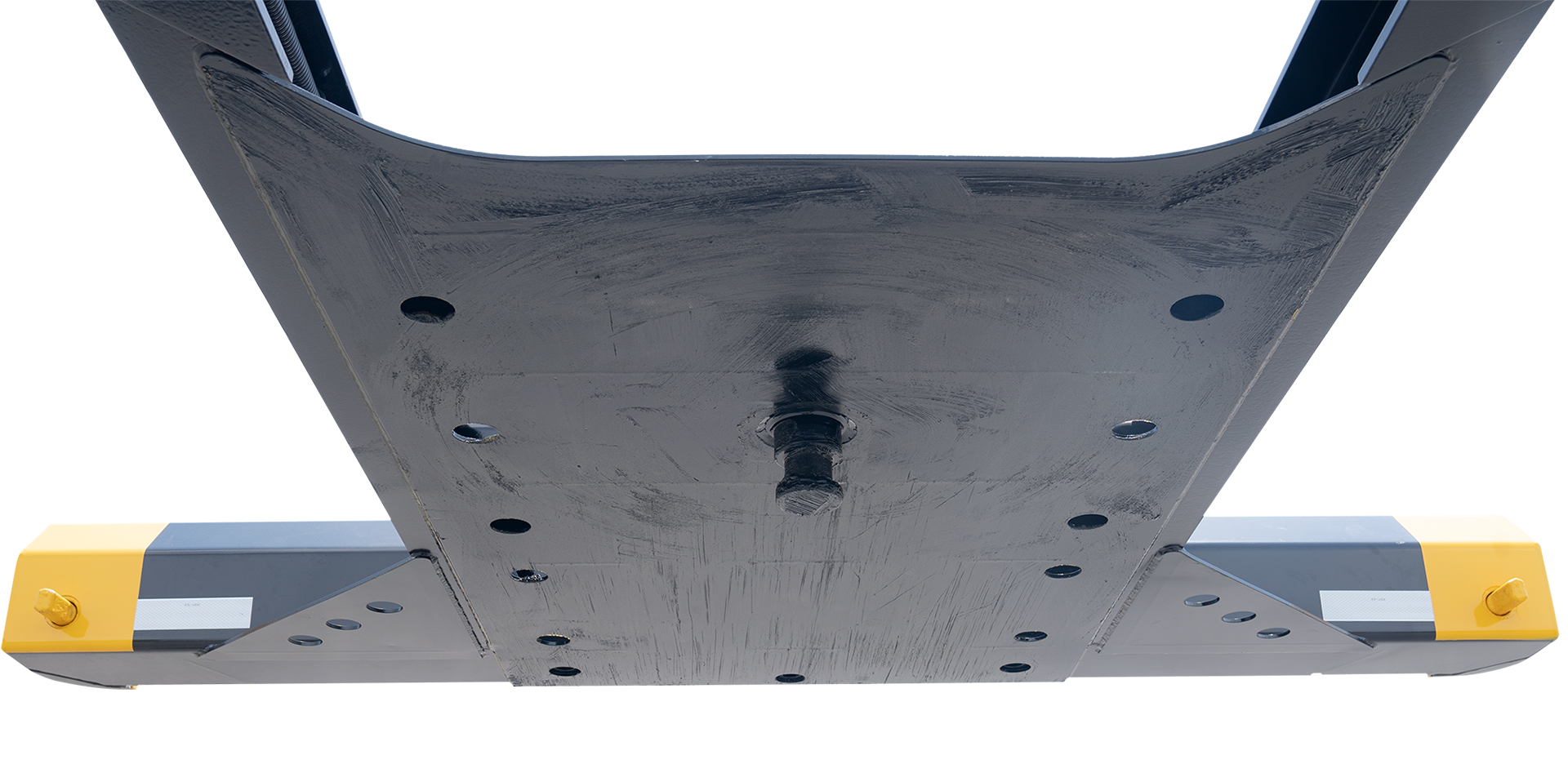

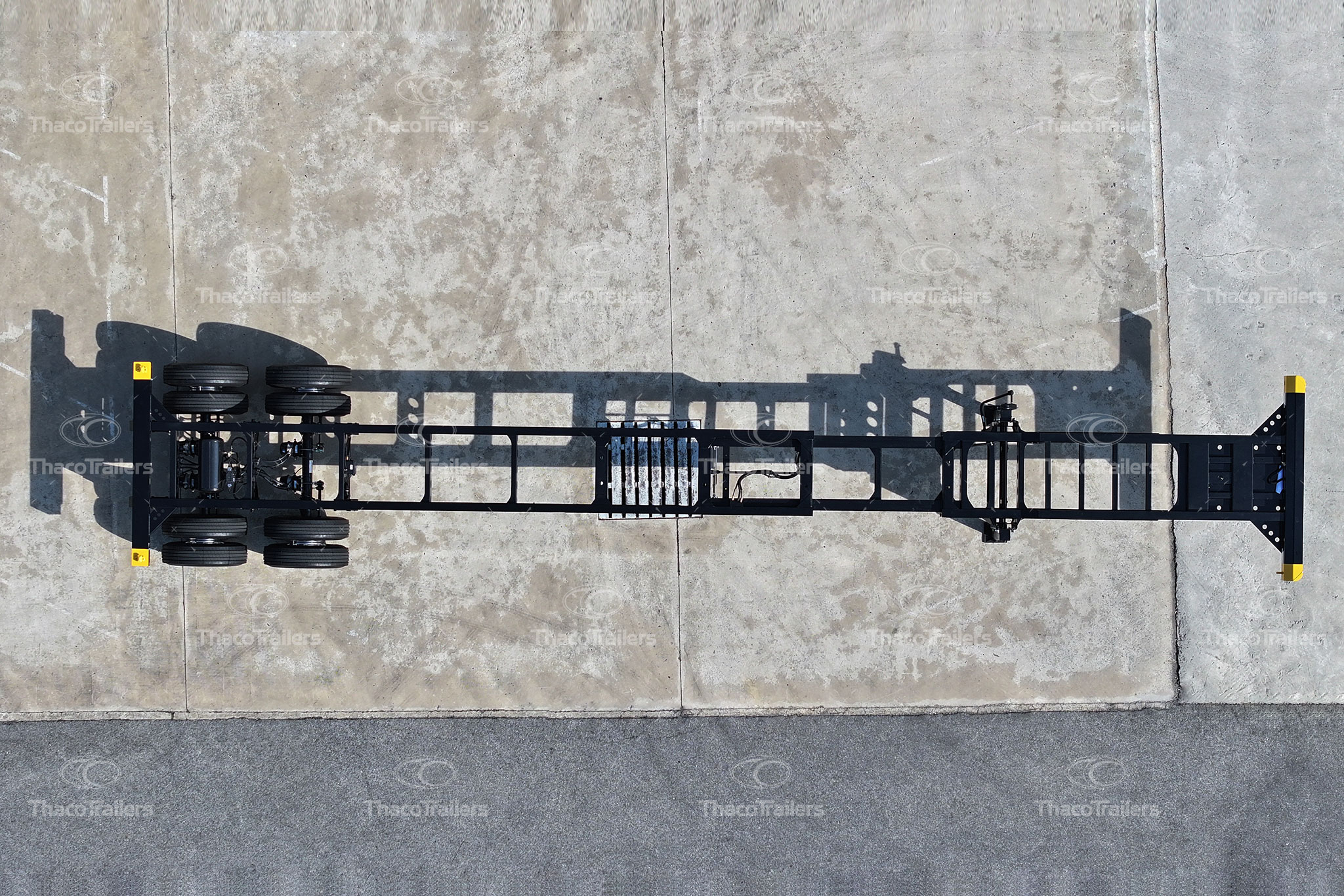

Kingpin Location: 30” (From rear face of front bolster)

Landing Gear Location: 100” (From the kingpin center)

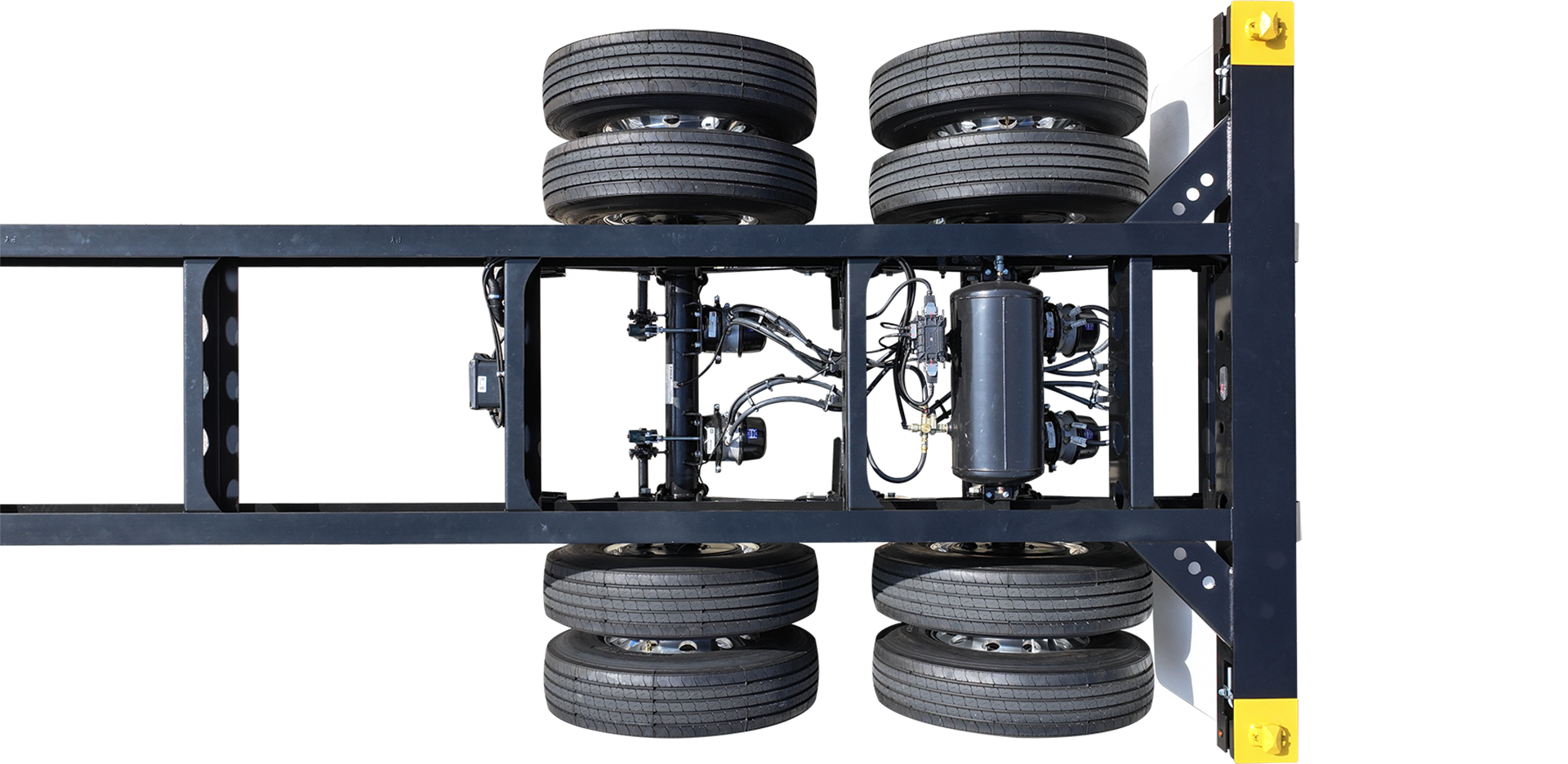

Tandem Location: 54” (From rear face of rear bolster)

Axle Spread: 49”

Tare Weight: 7,300 lbs±3%

Payload: 67,200 lbs (30,480kgs)

Color on request

-

Specifications

- Warranty Policy

| Main beam | W12@19lb/ft hot-rolled H-beam, ASTM A572 Grade 50 or equivalent. |

| Cross member | 3/16” thick x 3” wide x 9” deep channel with profiled bar type diagonal brace. |

| GN member | 5-1/4” deep x 4” wide hot-rolled H-beam, ASTM A572 Grade 50 or equivalent, with 1/2” thick flanges and 1/4” thick web. |

| Upper Coupler | 1/4” pick up plate with 2” diameter square type king pin per SAE standard, 380-420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Front Bolster | 8” wide x 10” high x 1/4” thick open section, with 3-1/2” chamfer in full length for gathering container in operation. 7-way receptacle and glad hands are in the center of front bolster. Bent corner caps. Option Cast corner caps. |

| Rear Bolster | 8” wide x 3/8” thick top plate with 7” wide x 6-5/8” deep x 1/4” thick “U” type bottom channel. |

| Rear Bumper | 4” x 4” square tube step with taper “H” section vertical member. Bar is welded to uprights and main beam. |

| License plate bracket | Extending from rear bolster within envelope of ICC bumper. Plate is to contain rear fleet number & license plate. |

| Frame Extension | 7-5/8” deep fabricated I-beam with 5-1/2”x3/8” flanges and 1/4” thick web. Easily operated self-locating and self-locking spring loaded pin mechanism is used to lock the frame. |

| Front Locking pin | 1103-1213-L/R. |

| Rear twist Lock | 1102-1259-L/R. |

| Landing Gear | 65,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Landing gear brackets are welded on the main beam as the layout. |

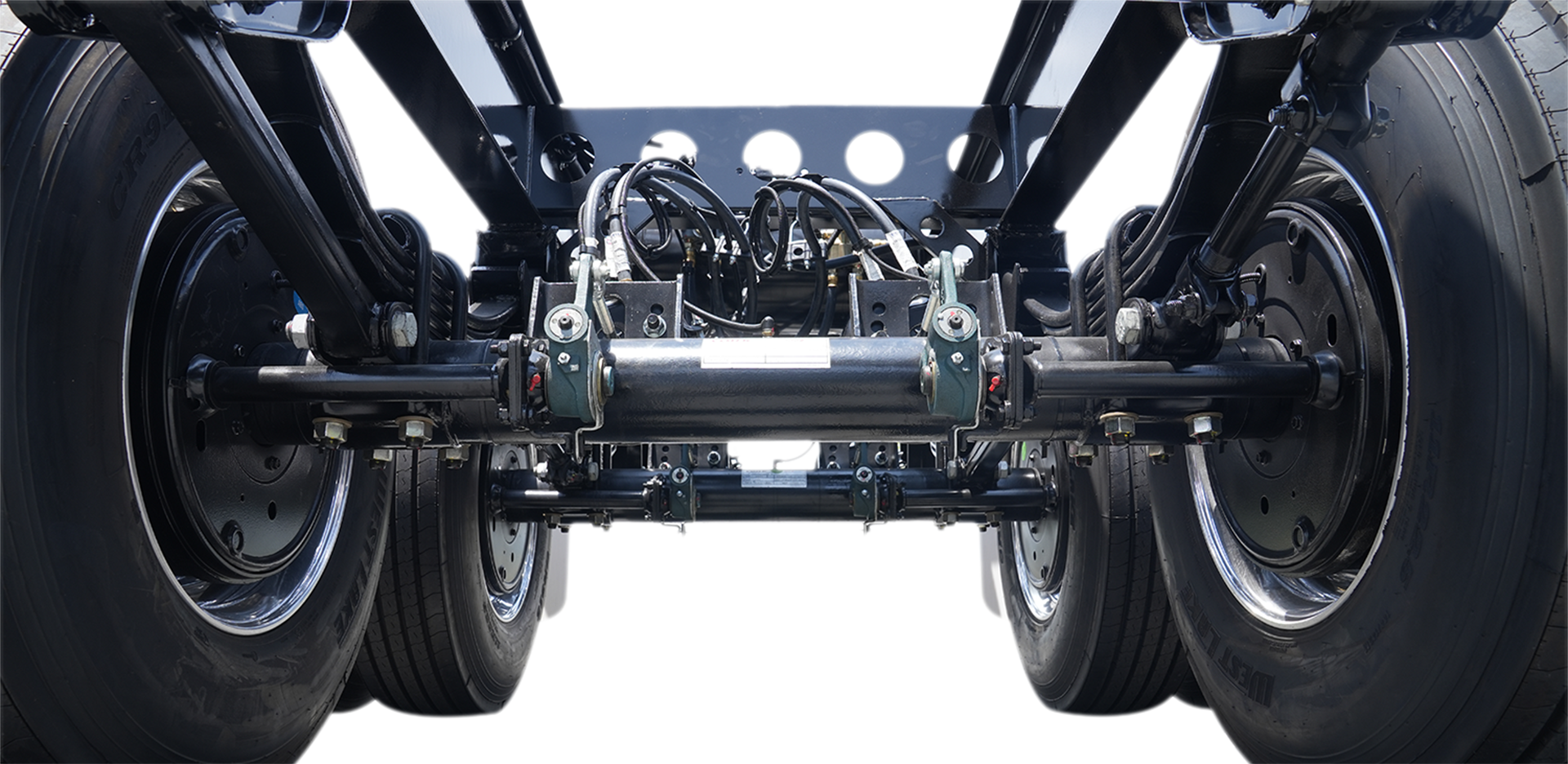

| Suspension | H9700 mechanical tandem suspension, overslung configuration with Thaco Springs (Vietnam) high-arch 3-leaf spring (354-00). |

| Axles |

|

| Wheel end | Hub & Drum Assembly. 340-4370 solid Aluminum Grease hub cap. Seals P/N Scotseal plus XL 46300. Bearings. Spindle nut Double Nut. |

| Lubricant | Synthetic Semi-fluid grease lubricant. |

| Wheels | 22.5 x 8.25 10-stud hub-piloted wheels with 5 hand holes and with TR572 valve stem. |

| Tires | 11R22.5-14PR tubeless type. |

| Brake System | 110800 spring brake priority valve system and 2S/1M ABS system. Glad hand 12-0061 and 12-0081. 3/8” blue air tube for control and 3/8” red for supply. Goldseal T30/30, 2.5” stroke brake chamber. THACO CMC (Vietnam) air tank. |

| Electrical | Mold seal wiring harness, Reserved PSI and GPS connector. LED lights (amp connections for S/T/T lights and 180 bullets for others). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | 16-724 plastic material with split pins. |

| Document Holder | THACO Plastic Components (Vietnam). Installed on roadside near crank handle. |

| Conspicuity tape | Installed per federal regulations. |

| Painting |

|

| Marking | Standard configuration (includes Decal, layout, VIN, nameplate). |

| Hubodometer | NONE. |

| Tire Inflation System | PSI (USA) Tire Inflation System with THERMalert. |

| Mud flaps | THACO Plastic Components (Vietnam) 24”x30”x1/4” White PVC mud flaps with “CUSTOMER” logo. |

Key Features of the 40’/45′ Extendable Tandem

Exceptional Flexibility

The 40’/45′ Extendable Tandem offers adjustable length from 40′-11” when retracted to 45′-11” when extended. This flexibility makes it ideal for transporting long or heavy loads, optimizing cargo space to meet various transportation needs.

High-Quality Extendable Chassis

The 40’/45′ Extendable Tandem is made from POSCO (Vietnam) W12@19lb/ft hot-rolled H-beam, ensuring strength and durability. The extendable frame locks securely with an automatic pin mechanism, offering ease of operation and increased efficiency.

Durability and Easy Maintenance

The 40’/45′ Extendable Tandem is coated with electrophoresis primer and powder topcoat to protect against corrosion. Key components like hub & drum assembly and bearings come with a 5-year warranty, ensuring long-term reliability.

Compliance with Federal Transportation Standards

The 40’/45′ Extendable Tandem complies with all federal transportation standards, including DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA certifications, ensuring its legal operation on U.S. roads.

Flexibility and Versatility of 40’/45′ Extendable Tandem

The Extendable Tandem offers great flexibility for transporting different loads, with its Extendable Chassis feature allowing the trailer length to adjust from 40′ to 45′. This is particularly beneficial for transporting long and bulky items like containers. The ability to adjust landing gear and axle spread ensures compatibility with various tractor units, providing safe and efficient operation.

This combination of flexibility, advanced safety systems, and durable construction makes the Extendable Tandem an ideal choice for diverse and dynamic transportation needs.

| No. | Part Name | Manufacturers Name | Time | Warranty Information |

| 1 | Frame | Thaco Trailers | 5 Years | THACO INDUSTRIES TRAILERS AND HEAVY STEEL STRUCTURES MANUFACTURING LIMITED LIABILITY COMPANY Add: Chu Lai IZ., Nui Thanh Commune, Da Nang City, Vietnam Office: (+84) 2353.565.327 Website: https://thacotrailers.com/ |

| 2 | Paint(ED + Top coat) | PPG | Painting: 7 Years |