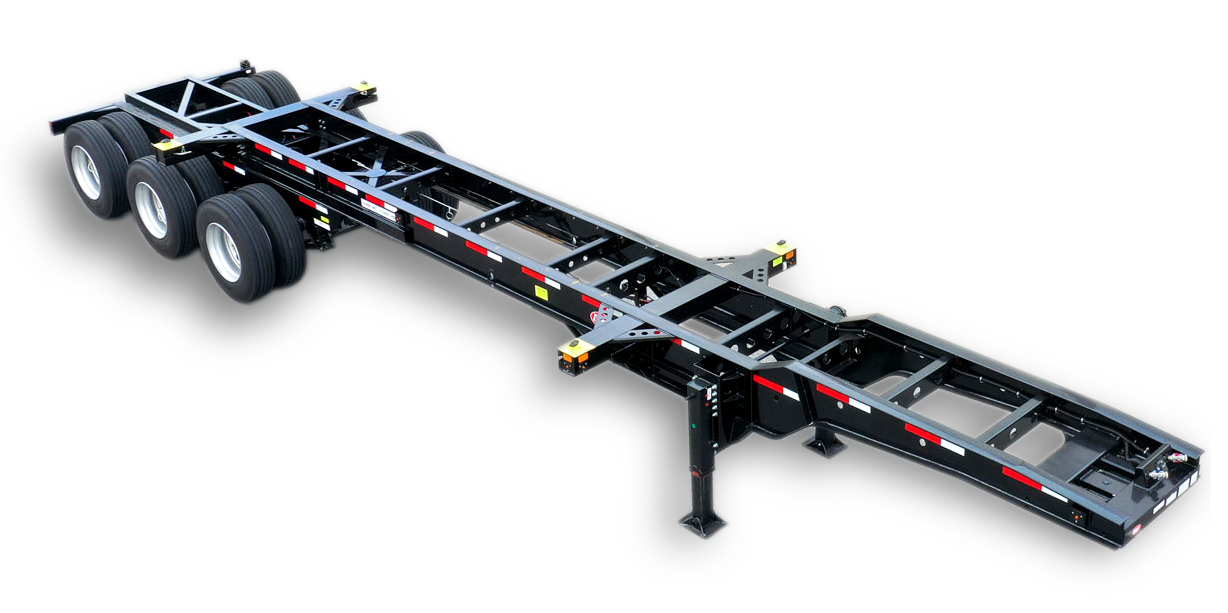

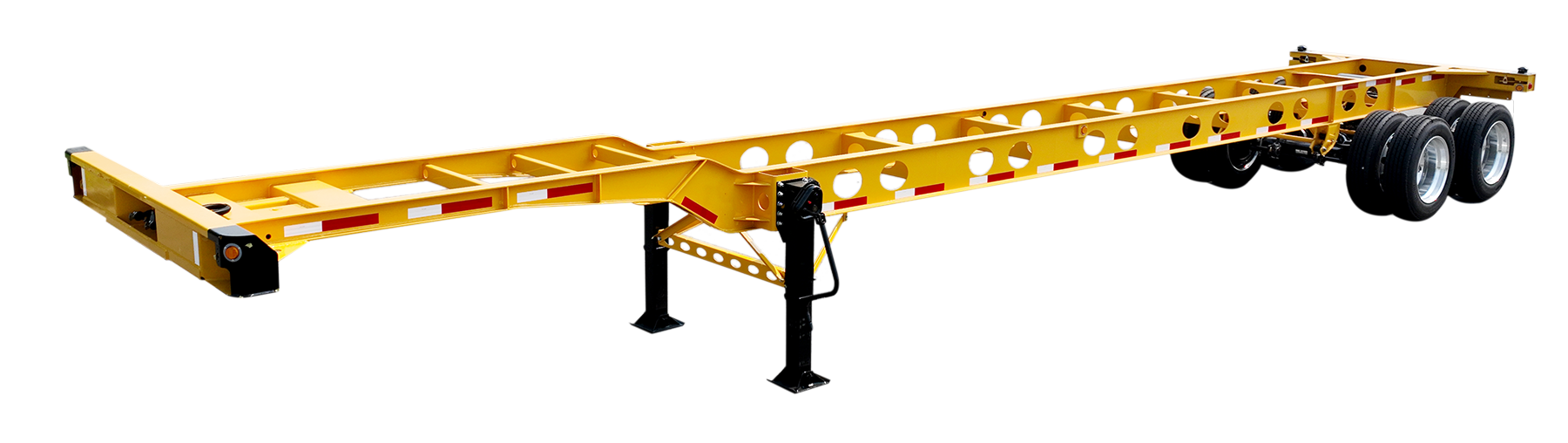

33′ Slider Tridem

Overall Length: 33’ (retracted) or 41’ (extended)

Overall Width” 96”

Fifth Wheel Height: 48 ± 1”

Rear Deck Height: 52 ± 1”

Kingpin Location: 15”

Landing gear location: 112” (From the kingpin center)

Tridem location: 16” (From rear face of rear bolster to rear axle center when extended)

Axle Spread: 54.5” + 54.5”

Tare Weight: 10,700 lbs ± 3%

Payload: 67,200 lbs

Product Details

Steel structure

We offer single-girder and double-girder designs for different operational needs.

When the crane span exceeds 100m, single-girder design is better:

- Needs much less steel to achieve same performance

- Offers lower weight: less foundation work

- Gives a greater load unbalance between the upper trolley hooks

Cabin

We offer single-girder and double-girder designs for different operational needs.

When the crane span exceeds 100m, single-girder design is better:

- Needs much less steel to achieve same performance

- Offers lower weight: less foundation work

- Gives a greater load unbalance between the upper trolley hooks

Core of Lifting

We offer single-girder and double-girder designs for different operational needs.

When the crane span exceeds 100m, single-girder design is better:

- Needs much less steel to achieve same performance

- Offers lower weight: less foundation work

- Gives a greater load unbalance between the upper trolley hooks

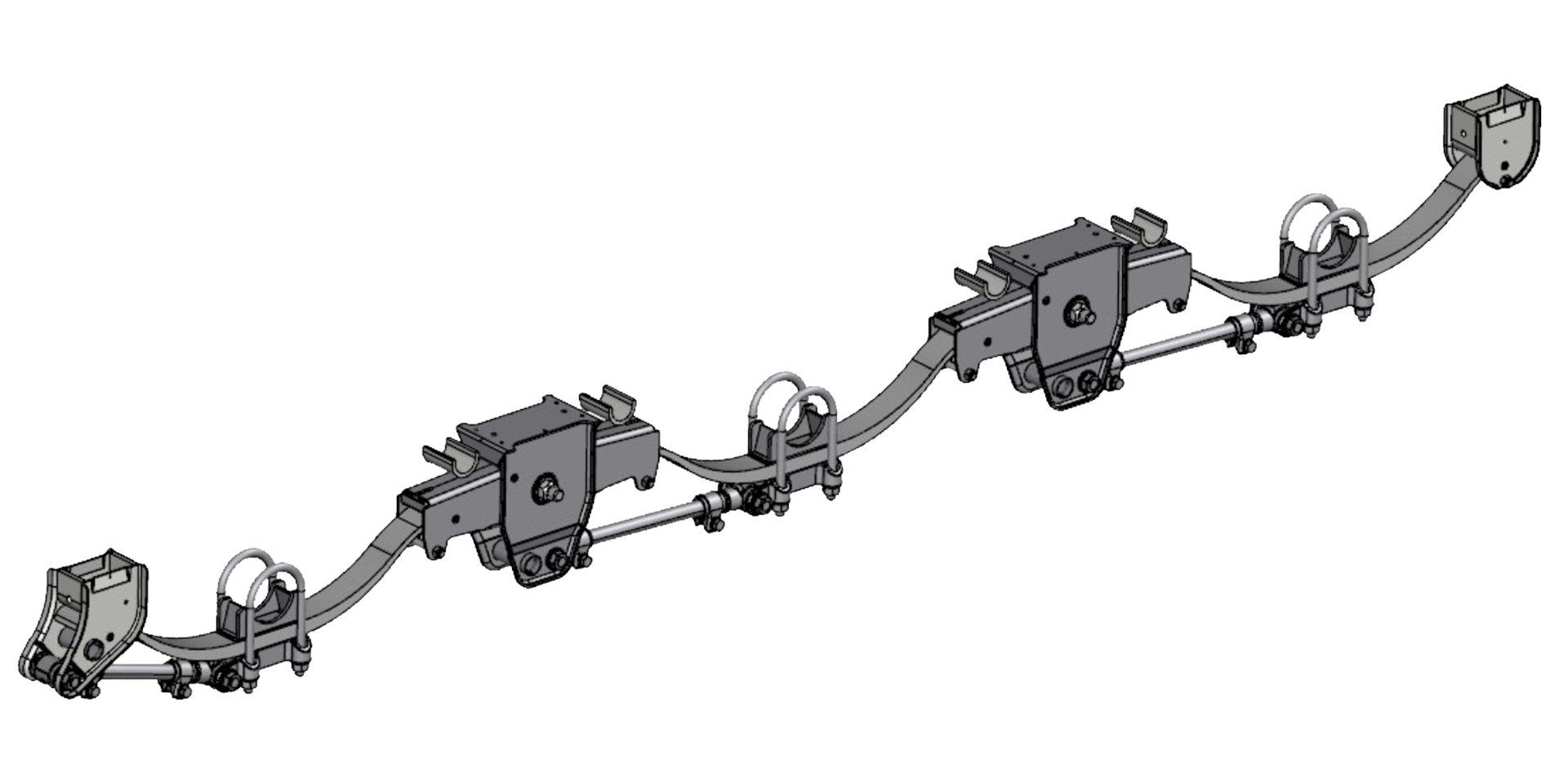

Bogies

We offer single-girder and double-girder designs for different operational needs.

When the crane span exceeds 100m, single-girder design is better:

- Needs much less steel to achieve same performance

- Offers lower weight: less foundation work

- Gives a greater load unbalance between the upper trolley hooks

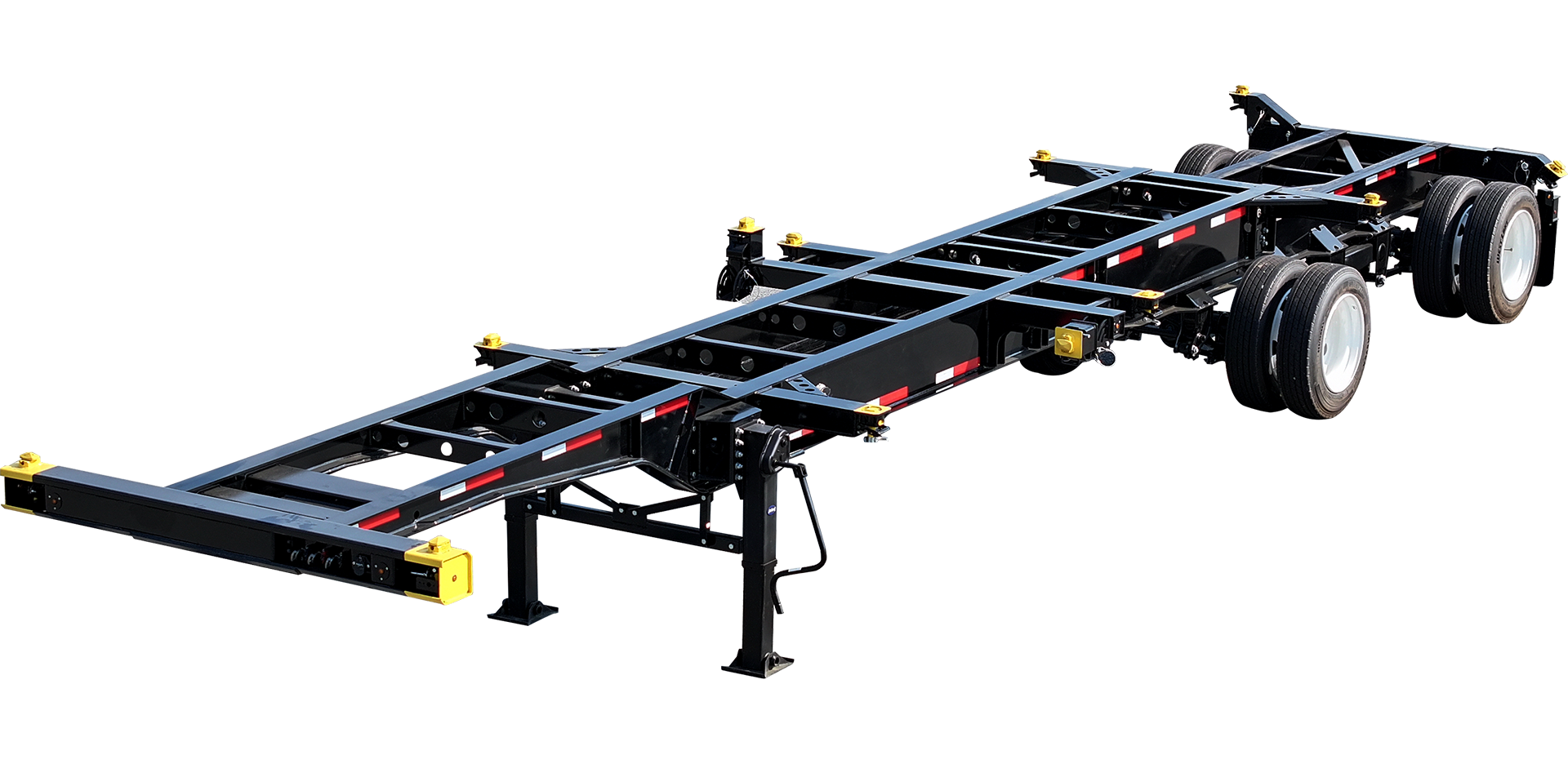

Specifications

Warranty Policy

| Main beam | Fabricated I-beam with high strength Grade 80 steel. |

| Cross member | 3/16” thick x 3” wide x 9” deep channel with profiled bar type diagonal brace. |

| Slider beam | 10” deep x 5” wide x 5/16” thick tube section. ASTM A-500 GR.B or equivalent. |

| Upper Coupler | 5/16” pick up plate with 2” diameter square type kingpin per SAE standard, 380-420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Bolsters | 8” wide x 3/8” thick top plate with 7” wide x 6-3/4” deep x 5/16” thick “U” type bottom channel. |

| Rear Bumper | 4” x 4” square tube step with taper “H” section vertical member. Bar is welded to uprights and main beam. |

| Twist Locks | Provided |

| Landing Gear | 65,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Landing gear brackets are welded on the main beam as the layout. |

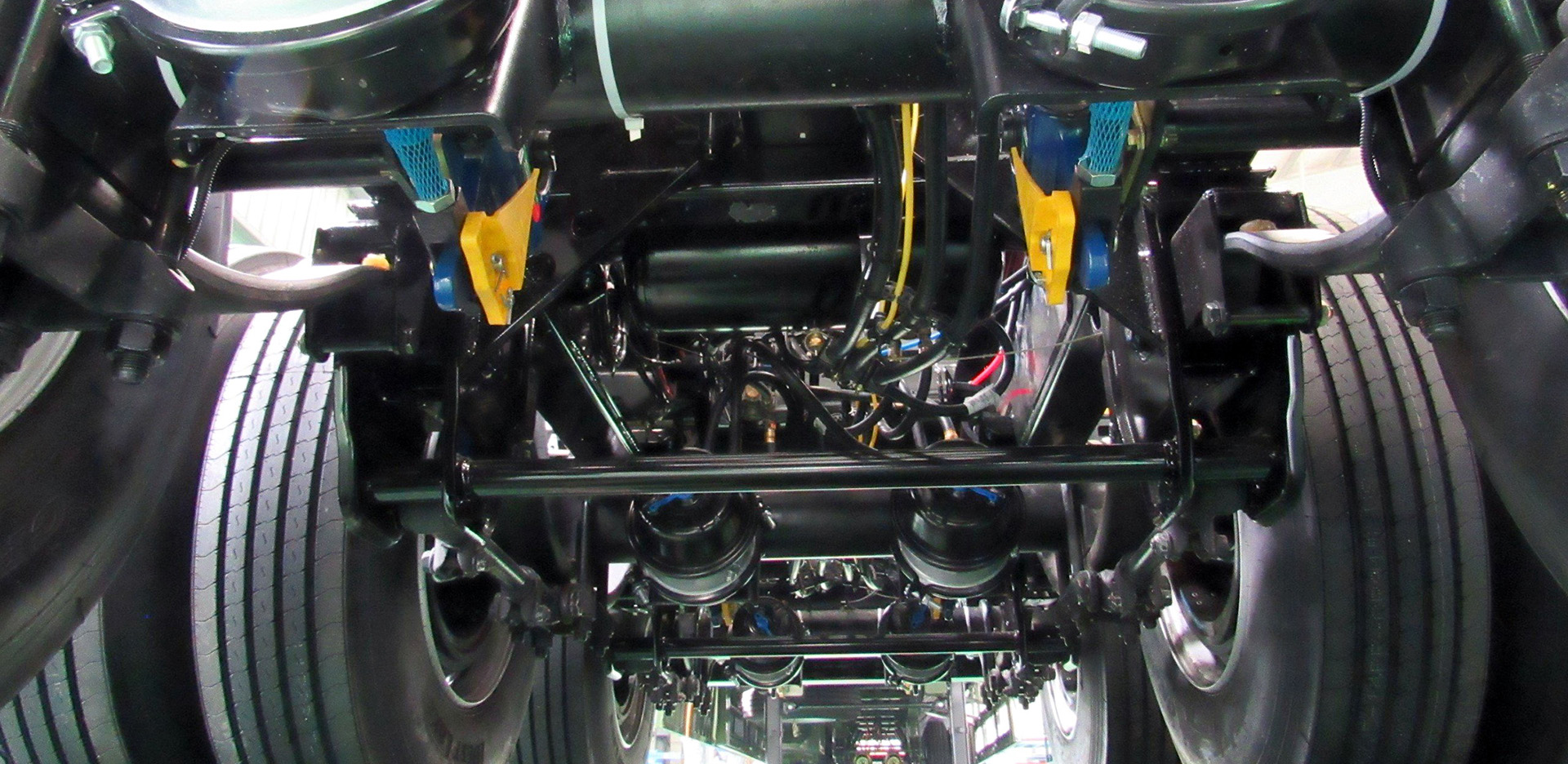

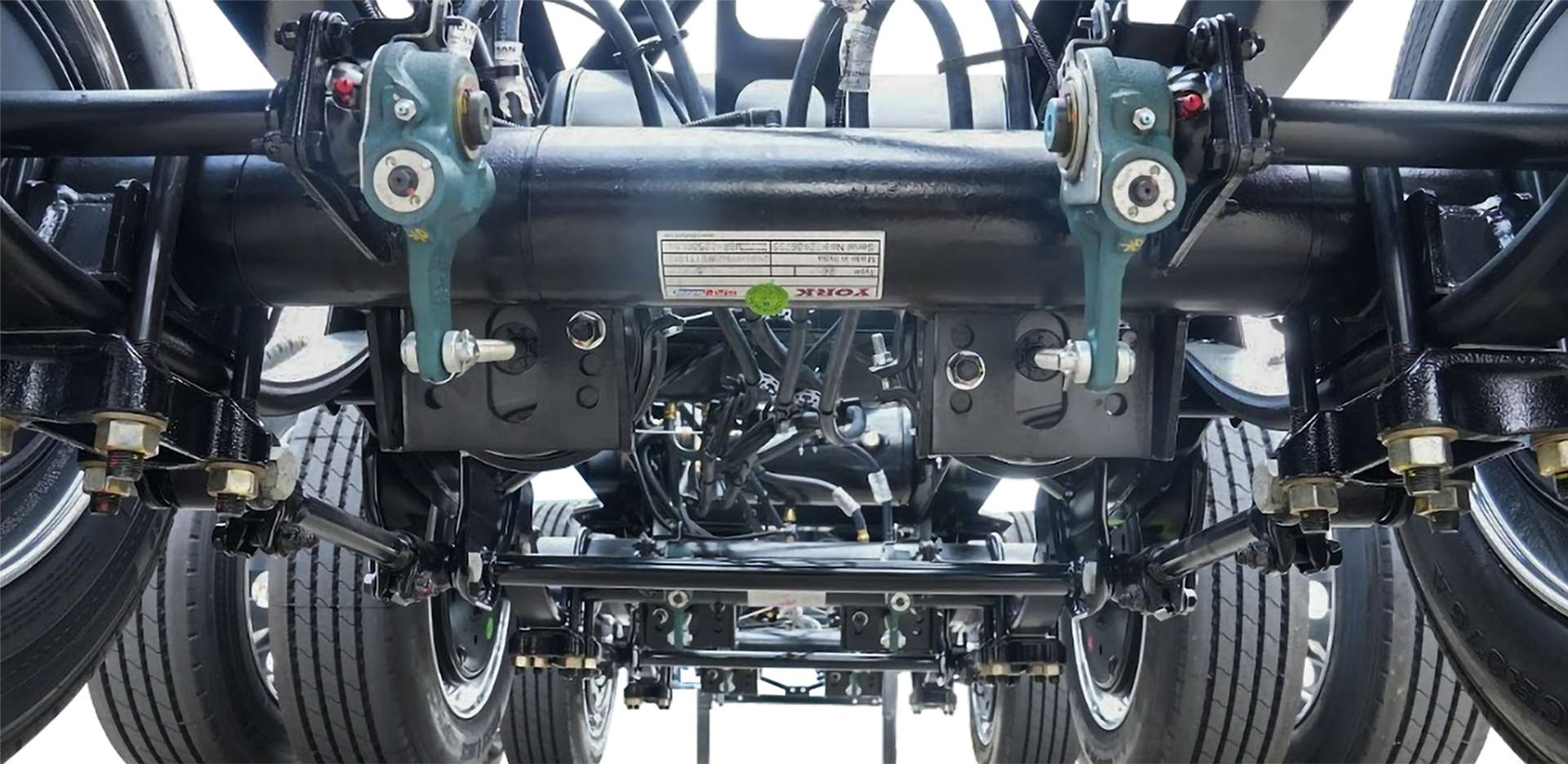

| Suspension | 54.5” tri-axle, underslung configuration with high arch single leaf spring (360-00). |

| Axles |

|

| Wheel end | Hub & Drum Assembly. 340-4370 solid Aluminum Grease hub cap. Seals P/N Scotseal plus XL 46300. Bearings. Spindle nut Double Nut. |

| Lubricant | Synthetic Semi-fluid grease lubricant. |

| Wheels | 22.5 x 8.25 10-stud hub-piloted wheels with 5 hand holes and with TR572 valve stem. |

| Tires | 11R22.5-14PR tubeless type. |

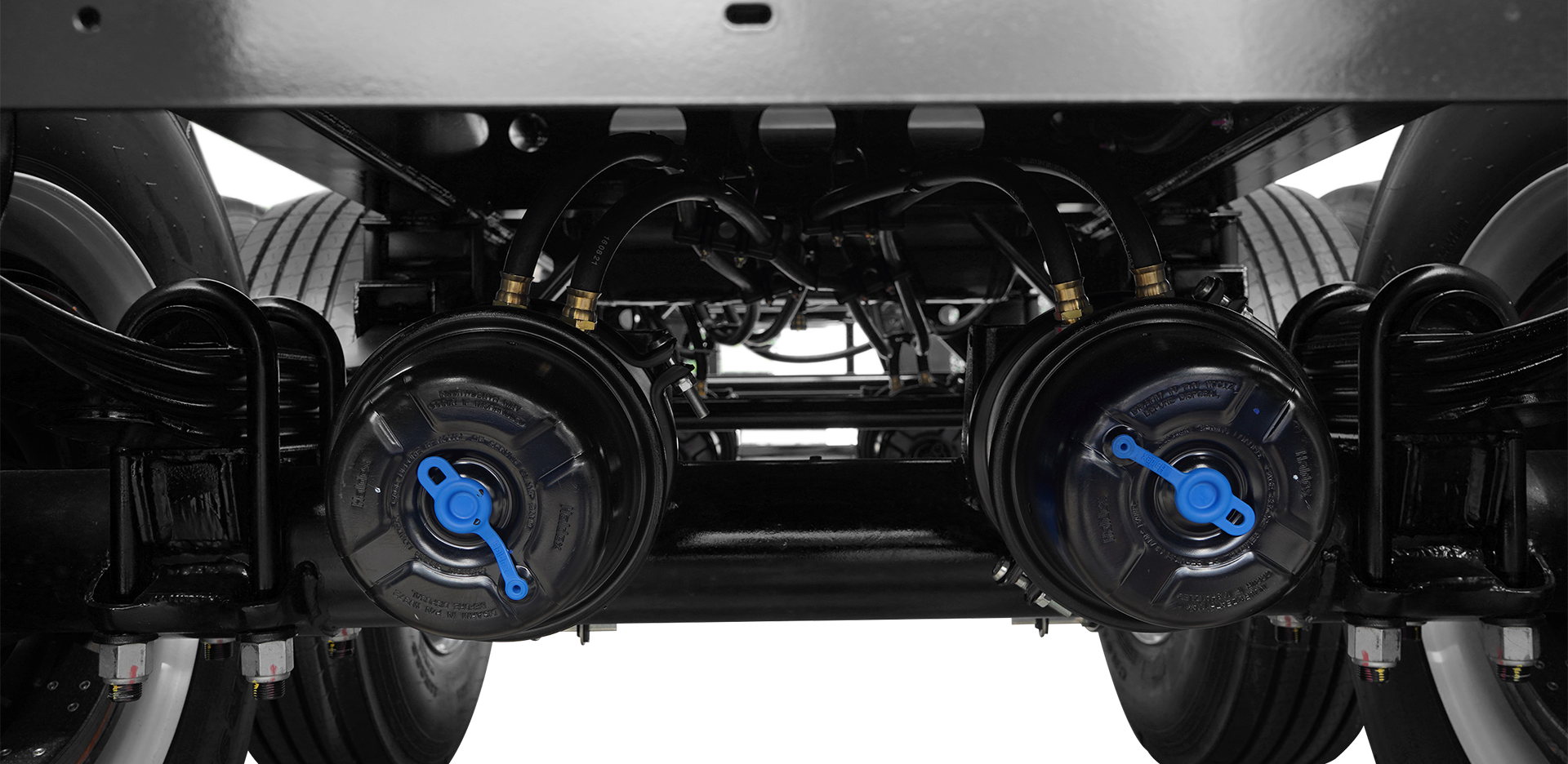

| Brake System | 110800 spring brake priority valve system and 4S/2M ABS system. Glad hand 12-0061 and 12-0081. 3/8” blue air tube for control and 3/8” red for supply. Goldseal T30/30, 2.5” stroke brake chamber. THACO CMC (Vietnam) air tank. |

| Electrical | Mold seal wiring harness, Reserved PSI and GPS connector. LED lights (amp connections for S/T/T lights and .180 bullets for others). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | 16-724 plastic material with split pins. |

| Document Holder | THACO Plastic Components (Vietnam). Installed on roadside near crank handle. |

| Conspicuity tape | Installed per federal regulations. |

| Painting | Abrasive blast of all metal surfaces – not less than SA-2.5 to achieve clean bare steel. Surface will be coated with electrophoresis primer and powder topcoat. Total thickness not less than 80μm after dry membrane. Coating supplier PPG (Vietnam). |

| Marking | Customer configuration (includes Decal, layout, VIN, nameplate). |

| Hubodometer | NONE |

| Tire Inflation System | PSI (USA) Tire Inflation System with THERMalert. |

| Mud flaps | THACO Plastic Components (Vietnam) 24”x24”x1/4” white PVC mud flaps with “CUSTOMER” logo. |

| No. | Part Name | Manufacturers Name | Time | Warranty Information |

| 1 | Frame | Thaco Trailers | 5 Years | THACO INDUSTRIES TRAILERS AND HEAVY STEEL STRUCTURES MANUFACTURING LIMITED LIABILITY COMPANY Add : Chu Lai IZ., Nui Thanh Town, Quang Nam province, Vietnam Office: (+84) 2353.565.327 Website: https://thacotrailers.com/ |

| 2 | Paint(ED + Top coat) | PPG | Painting: 7 Years |