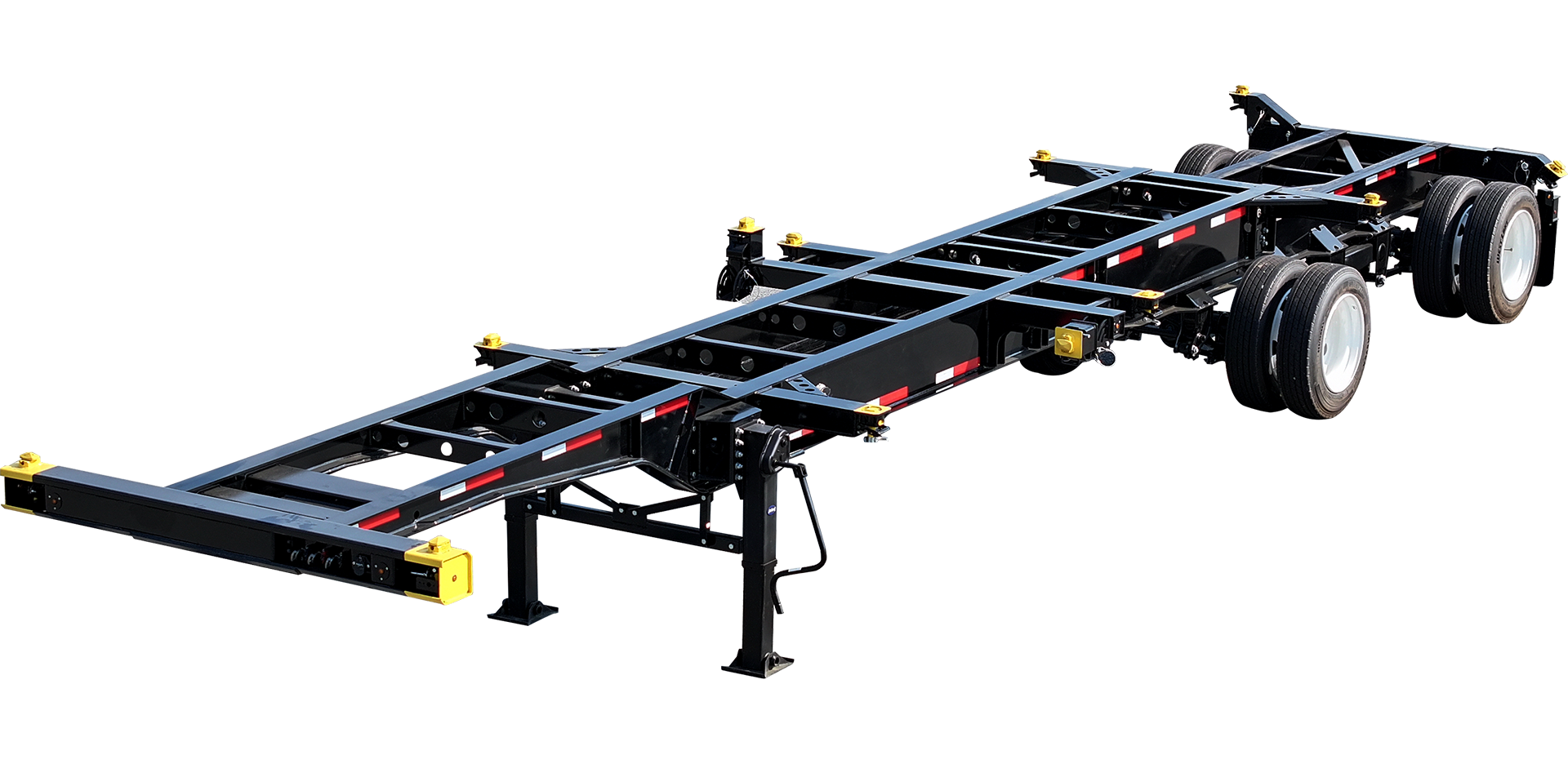

40′ Gooseneck Lightweight Tandem

Overall Length: 40’-11”

Overall Width: 96”

Overall Height: 58”

Fifth Wheel Height: 48 ± 1”

Rear Deck Height: 48 ± 1”

Kingpin Location: 18” (From rear face of front bolster)

Landing Gear Location: 110” (From the kingpin center)

Tandem Location: 52” (From rear face of rear bolster)

Axle Spread: 49”

Tare Weight: 5,250 lbs ±2%

Payload: 67,200 lbs (30,480kgs)

-

Specifications

- Warranty Policy

| Main beam | 13.75” deep x 4″ wide fabricated H-beam, 5/16″ thick Grade 100 steel flange and 1/4″ thick Grade 50 web |

| Cross member | 3/16” thick x 3” wide x 9” deep channel with profiled bar type diagonal brace. |

| GN member | 5-1/4” deep x 4” wide fabricated H-beam, 5/16” thick flanges and 1/4” thick web. |

| Upper Coupler | 1/4” pick up plate with 2” diameter square type king pin per SAE standard, 380-420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Rear Bolster | 8” wide x 5/16” thick top plate with 7” wide x 6-5/8” deep x 3/16” thick “U” type bottom channel fabricated by Grade 100 steel. |

| Rear Bumper | 4” x 4” square tube step with taper “H” section vertical member. Bar is welded to uprights and main beam. |

| License plate bracket | Extending from rear bolster within envelope of ICC bumper. Plate is to contain rear cluster lights, rear fleet number & license plate. |

| Front Locking pin | Provided |

| Rear twist Lock | Provided |

| Landing Gear | 65,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Landing gear brackets are welded on the main beam as the layout. |

| Suspension | Mechanical tandem lightweight suspension with low-arch single spring (363-00). |

| Axles |

|

| Wheel end |

|

| Lubricant | Petro Canada Precision Synthetic EP00 Semi Fluid Grease lubricant. |

| Wheels | 22.5 x 8.25 hub-piloted Aluminum wheels. |

| Tires | 255/70R22.5-16PR tubeless type. |

| Brake System | 110800 spring brake priority valve system and 2S/1M ABS system. Glad hand 12-0061 and 12-0081. 3/8” blue air tube for control and 3/8” red for supply. Goldseal T30/30, 2.5” stroke brake chamber. THACO CMC (Vietnam) air tank. |

| Electrical | Mold seal wiring harness, Reserved PSI and GPS connector. LED lights (amp connections for S/T/T lights; PL-10 for Marker/ID/ABS lights and .180 bullets for license light). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | Provided |

| Document Holder | THACO Plastic Components (Vietnam). Installed on roadside near crank handle. |

| Conspicuity tape | Installed per federal regulations. |

| Painting |

|

| Marking | Standard configuration (includes Decal, layout, VIN, nameplate). |

| Hubodometer | NONE. |

| Tire Inflation System | PSI (USA) Tire Inflation System with THERMalert. |

| Mud flaps | THACO Plastic Components (Vietnam) 30”x24”x1/4” White PVC mud flaps without “customer” logo. |

Key benefits of using the Gooseneck Light Weight Tandem

Optimized Cargo Capacity with Lightweight Design

The Gooseneck Light Weight Tandem is designed with a lightweight structure, maximizing cargo capacity while ensuring compliance with weight regulations. Thanks to its hollowed structure that still supports a payload of up to 67,200 lbs (30,480 kgs), this product allows for transporting more goods in a single trip, reducing the number of trips and saving transportation costs. The combination of lightweight and high operational efficiency also helps significantly reduce fuel costs and emissions, offering a sustainable transportation solution for your business.

Highly Durable Frame for Long-Term Use

The frame of the Gooseneck Light Weight Tandem is meticulously engineered to ensure exceptional durability and strength. Despite the hollowed design to reduce weight, the frame retains the ability to carry heavy payload without compromising durability. This ensures the product not only delivers high performance but also offers a long lifespan, giving you peace of mind for years of reliable use without concerns about damage or breakage.

Compliance with Federal Transportation Standards

The 40′ Gooseneck Light Weight Tandem from Thaco Trailers fully complies with federal transportation standards, including DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA certifications. This ensures the product’s legal and efficient operation on North American roadways.

Innovative design and creative engineering

Advanced engineering

This lightweight gooseneck trailer incorporates a modern LED lighting system and precision-engineered synthetic lubricants for the wheels, enhancing safety and longevity. The trailer’s frame is constructed from high-strength steel alloy with strategically placed holes in the frame structure, reducing overall weight without compromising durability. Additionally, the wheel end is engineered with advanced lightweight materials, further contributing to the trailer’s reduced weight. The use of aluminum rims further lowers the trailer’s overall weight, optimizing fuel efficiency and reducing emissions. The Q+ brake system ensures reliable braking under heavy loads.

Optimized load distribution for superior stability

The tandem lightweight suspension system and fabricated H-beams in the lightweight gooseneck trailer ensure even load distribution, enhancing stability during transportation. This design innovation maximizes efficiency for heavy-duty operations while maintaining smooth and controlled handling.

| No. | Part Name | Manufacturers Name | Time | Warranty Information |

| 1 | Frame | Thaco Trailers | 5 Years | THACO INDUSTRIES TRAILERS AND HEAVY STEEL STRUCTURES MANUFACTURING LIMITED LIABILITY COMPANY Add : Chu Lai IZ., Nui Thanh Town, Quang Nam province, Vietnam Office: (+84) 2353.565.327 Website: https://thacotrailers.com/ |

| 2 | Paint(ED + Top coat) | PPG | Painting: 7 Years |