TOP 5 BENEFITS OF USING SLIDER CHASSIS IN CONTAINER TRANSPORT

In the fast-growing world of container transport, efficiency and adaptability are critical for staying competitive. Slider chassis, designed to handle containers of various sizes, offers remarkable flexibility, space optimization, and cost savings. In this article, Thaco Trailers will delve into the benefits of slider chassis and explore how to choose the right one.

1. What is a slider chassis?

A slider chassis is a specialized type of trailer chassis engineered to transport intermodal containers of varying sizes. It features an extendable frame capable of sliding forward and backward, accommodating containers of 20-foot, 40-foot, and even 45-foot lengths. This adaptability makes slider chassis a preferred choice for trucking companies in container transport, as it enables one chassis to handle multiple container sizes, significantly optimizing fleet efficiency.

Key features of a slider chassis:

- Extendable Frame: Adjusts to fit multiple container lengths.

- Locking Mechanism: Ensures stability by securely holding containers in place.

- Compatibility: Suitable for different intermodal container types.

- Increased Flexibility: Ideal for dynamic operations requiring size adjustments.

>> Read more: What is a shipping container chassis? Types and uses explained

2. Benefits of using slider chassis in container transport

2.1 Versatility in handling multiple container sizes

Slider chassis offers exceptional versatility in handling multiple container sizes, making them indispensable in container transport. Their adjustable frames accommodate various standard container lengths, such as 20-foot, 40-foot, and 53-foot containers, eliminating the need for multiple chassis types. This flexibility enhances operational efficiency and cost savings and improves safety and stability by securely fastening containers during transit.

2.2 Reduce Fleet Costs

Slider chassis significantly reduce fleet costs in container transport by eliminating the need for diverse fixed-size chassis. Their adaptability allows companies to streamline their fleet, lowering expenses related to storage, maintenance, and insurance. Additionally, enhanced utilization rates and reduced downtime contribute to greater operational efficiency and cost savings.

2.3 Enhanced Safety and Stability

Slider chassis enhance safety and stability in container transport by allowing adjustable load positioning to optimize weight distribution, reducing the risk of tipping and improving vehicle handling. Their ability to ensure compliance with axle load regulations minimizes fines, enhances road safety, and improves weight distribution. Additionally, these chassis perform well in adverse conditions and improve braking efficiency, ensuring secure operations and protecting both cargo and drivers.

2.4 Compliance with Road Regulations

Slider chassis support compliance with road regulations by enabling precise weight and size adjustments, ensuring proper axle load distribution, and adherence to height and weight limits. Their adaptability accommodates various container sizes, helping logistics companies avoid fines and legal issues while meeting regulatory standards. Additionally, their flexibility facilitates cross-border transport by aligning with diverse regional requirements, ensuring efficient operations.

2.5 Optimized Space Utilization

Slider chassis optimize space utilization in container transport by adjusting to accommodate various container sizes, such as 20-foot, 40-foot, and 45-foot containers, ensuring efficient use of cargo space. This adaptability reduces empty hauling and allows operators to consolidate loads effectively, maximizing payloads per trip. Additionally, their efficient design streamlines loading, unloading, and fleet management, saving storage space and reducing operational costs.

3. Key factors in choosing the right slider chassis

Selecting the suitable slider chassis is a crucial decision for any business involved in logistics and transportation. The right chassis ensures efficient operations and helps control costs over time. Below are the key factors to consider when choosing the right slider chassis for your needs:

3.1 Determine Payload Capacity

The payload capacity of a chassis should align with the weight of the cargo it is designed to carry. For businesses that transport heavy loads, such as construction equipment or industrial machinery, selecting a chassis with a higher weight capacity and enhanced stability features is critical. A robust chassis will ensure the safe and efficient transport of these heavy loads while maintaining performance standards. Conversely, for businesses dealing with lighter loads, a standard capacity chassis may suffice.

3.2 Transportation Routes

The type of transportation routes you operate on plays a significant role in selecting the right chassis. If your routes involve traveling on rough, uneven roads or require long-distance travel, it is important to choose a chassis equipped with a durable suspension system to ensure stability and minimize wear and tear. Furthermore, businesses transporting specialized goods, such as hazardous materials or perishable items, must ensure the chassis meets local safety regulations and is equipped with the necessary features to handle these specific requirements.

3.3 Size Requirements

Choosing the correct chassis size is one of the most critical factors in ensuring operational efficiency and safety. In the market, standard chassis sizes are typically 20ft, 40ft, and 45ft, with the 40ft chassis being the most common due to its versatility for standard container sizes. However, the right size depends largely on the nature of the cargo:

- For businesses that transport larger or bulkier items, such as industrial machinery or heavy containers, a 45ft chassis may be required. In contrast, businesses that handle smaller, lighter goods may opt for a 20ft chassis to optimize space and reduce unnecessary weight.

- When transporting temperature-sensitive products, such as food or pharmaceuticals, or hazardous materials, businesses must select a chassis designed to accommodate these special requirements. This may include features such as temperature control systems, reinforced structures, or additional safety measures.

3.4 Budget Considerations

When choosing a slider chassis, businesses should evaluate the initial purchase price, but they must also factor in the total cost of ownership, including maintenance, fuel efficiency, and potential repairs. Opting for a higher-quality chassis may involve a higher initial investment but can lead to significant savings in the long term, thanks to reduced downtime, fewer repairs, and lower operational costs.

>> Read more: How to choose the right 40ft container chassis for logistics needs

4. Maintenance tips for slider chassis

4.1 Regular inspection for wear and tear

Regular inspections are crucial to identify signs of wear and tear, which can affect the performance and safety of your slider chassis.

- Check the frame for any cracks, rust, or stress marks, especially after long trips or when carrying heavy loads, as these can indicate wear and tear.

- Inspect the locking mechanisms and adjustable parts to ensure they are still functioning correctly, as wear can cause them to loosen or fail.

- Look for damage in the slider system that could cause misalignment or instability, which could lead to further wear and compromise the chassis.

Regularly checking for these issues helps prevent major damage and ensures the chassis continues to perform safely and efficiently.

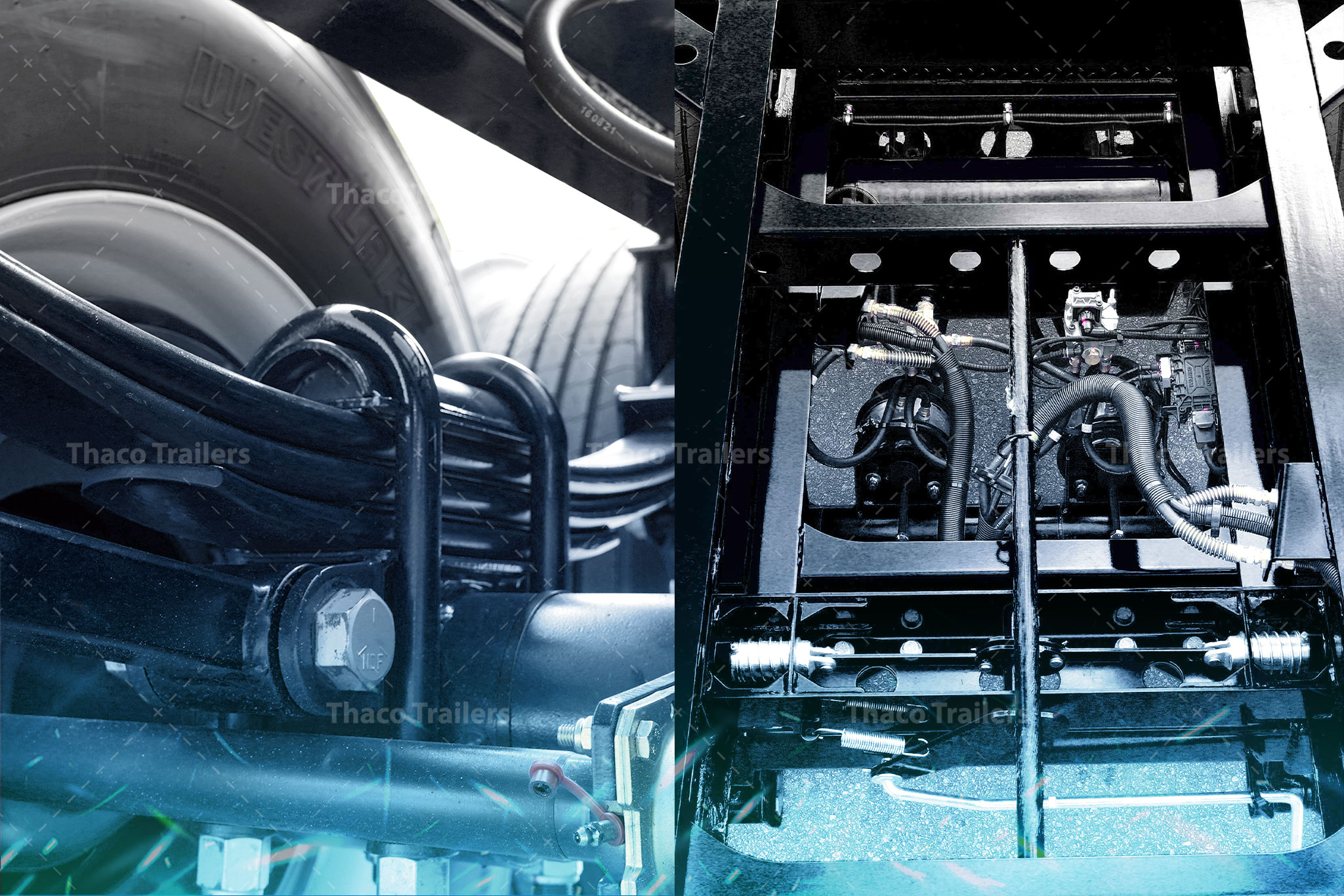

4.2 Lubrication and Tire Care

Lubricating parts and checking tires are key to keeping your chassis running stably and extending its life.

- Lubricate moving parts such as the slider rails and suspension joints to reduce friction and wear.

- Check tire pressure regularly to make sure the tires are properly inflated. Underinflated tires can cause more wear and reduce fuel efficiency.

- Inspect the tires for damage such as cuts, bulges, or uneven wear. Replace them if needed to ensure safe driving.

4.3 Brakes and Suspension check

The brakes and suspension are crucial for the safety and stable operation of your chassis.

- Check the brake parts regularly, such as the pads and drums, for wear or issues. Make sure the braking system works well for safe stopping distances.

- Inspect the suspension for signs of damage, such as leaks or broken parts, and make sure everything is properly aligned for stability, especially when carrying heavy loads.

By following these maintenance tips, you can help prevent problems, extend the life of your slider chassis, and keep your operations running safely.

5. Should businesses consider choosing a new or used slider chassis?

Choosing between a new or used slider chassis depends on your financial capacity and operational needs. Below is a detailed analysis of the advantages and disadvantages of each option, with clear explanations to help you make the best decision.

5.1 Pros and cons of a new slider chassis

Pros:

- Superior Quality: New slider chassis is produced of original parts; they fully meet the quality and technical requirements. As a result, it ensures long-lasting durability, fewer breakdowns, and lower maintenance costs during the initial usage period.

- Comprehensive Warranty Policies: When purchasing a new slider chassis, you benefit from full warranty coverage provided by the manufacturer. This means that any issues during the warranty period will be resolved at no extra cost, giving you peace of mind.

- Customized to Your Needs: A new slider chassis can be designed and manufactured to meet specific requirements, such as dimensions, load capacity, and unique features. For example, if you need a 45ft chassis with high load capacity, a new product can be tailored precisely to meet these needs without any limitations.

Cons:

- High Initial Cost: Buying a new product typically requires a larger upfront investment compared to a used one. This can be a challenge for customers with limited budgets or those seeking more economical solutions.

5.2 Pros and cons of a used slider chassis

Pros:

- Lower Cost: If you prefer a lower first cost, a used slider chassis would be more appropriate since it has a much lower price than a new one. This is especially advantageous especially if the chassis will only be needed for a short while or for lower capacity uses.

Cons:

- Higher Maintenance and Repair Costs: A used chassis usually has some level of wear and tear. This means you may face frequent maintenance and repair costs, such as replacing components or fixing unexpected issues.

- Uncertain Quality: Not all used products are of good quality. Some used slider chassis may have hidden issues that are not immediately visible to the buyer. If you don’t thoroughly inspect the product or buy from a reputable supplier, there is a risk of purchasing a low-quality product, leading to poor performance and high repair costs.

- Limited Sizes and Configurations: Cost-effective products have less variety of sizes and configurations which are necessary to meet detailed requirements. For instance, if you require a 45ft slider chassis but only 40ft options are available on the used market, you’ll have to compromise. This limitation could impact your operational efficiency and the ability to meet job requirements.

>> Read more: Top Container Chassis Manufacturer Exporter To The US

6. Thaco Trailers offers outstanding slider chassis products in various sizes to meet your diverse needs

Thaco Trailers offers high-quality slider chassis in various sizes (40’/45’/48’/53′). Each chassis can be tailored to your exact specifications, ensuring optimal performance for your business.

Our advanced manufacturing facility is equipped with cutting-edge technologies, including fiber laser cutting, CNC brake press machines, and automated welding robots,… guaranteeing precision and reliability in every detail. To enhance durability and performance, we source materials from globally recognized suppliers such as Hyundai Steel, POSCO, HUTCH, YORK, SAF-HOLLAND, JOST, and more.

Additionally, we adhere to international quality standards, including ISO 9001:2015 and ISO 14001:2015, ensuring strict quality control, environmental responsibility, and consistent product reliability. Thaco Trailers’ slider chassis also comply with North American standards, including DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA, meeting stringent safety and performance requirements. Whether you need a standard or customized slider chassis, Thaco Trailers provides tailored solutions that enhance operational efficiency and meet the unique demands of your business.

>> Read more: Thaco Trailers attends ATA-TMC Annual Meeting 2024

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn