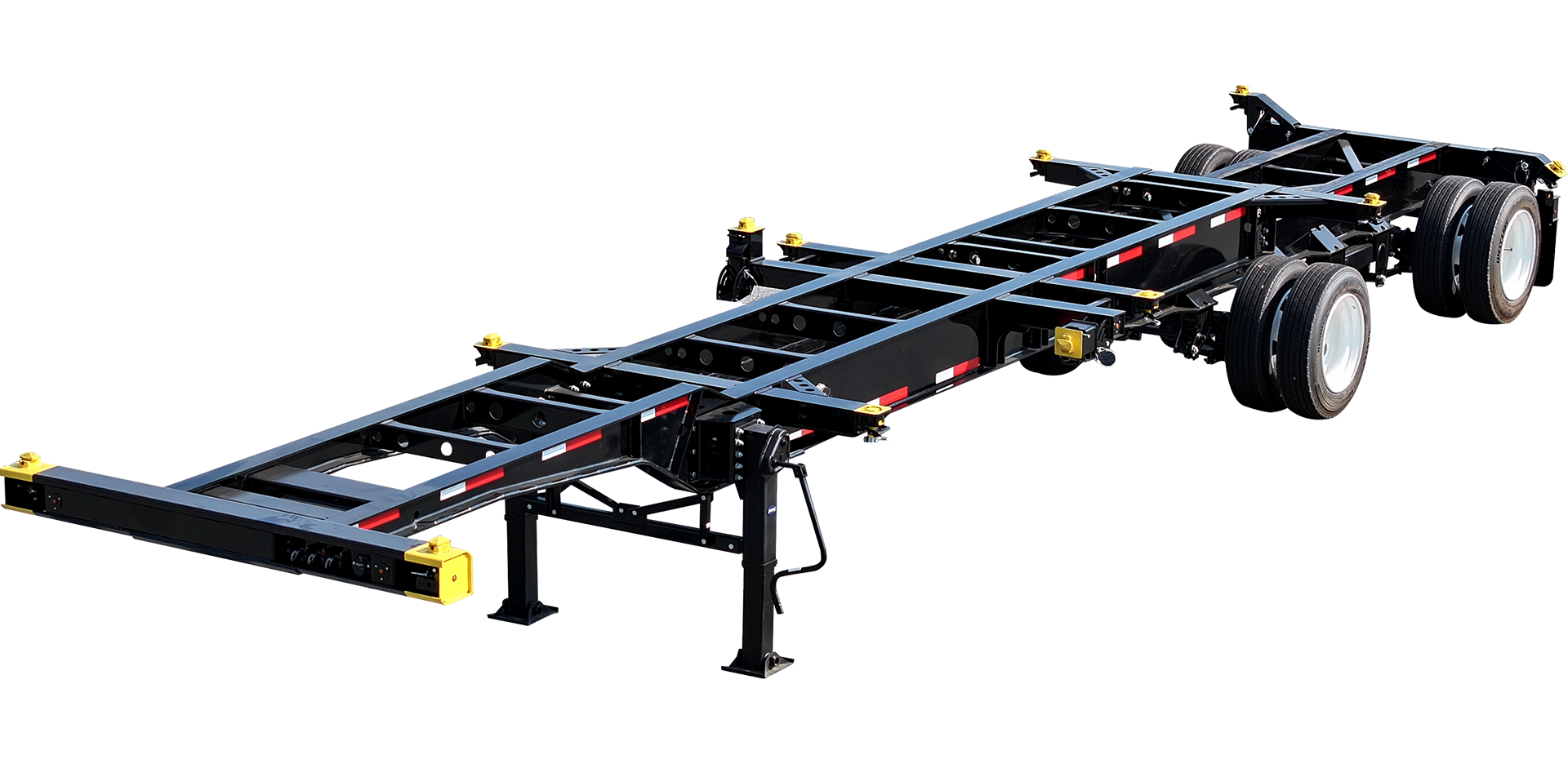

20’/40′ Combo Tandem

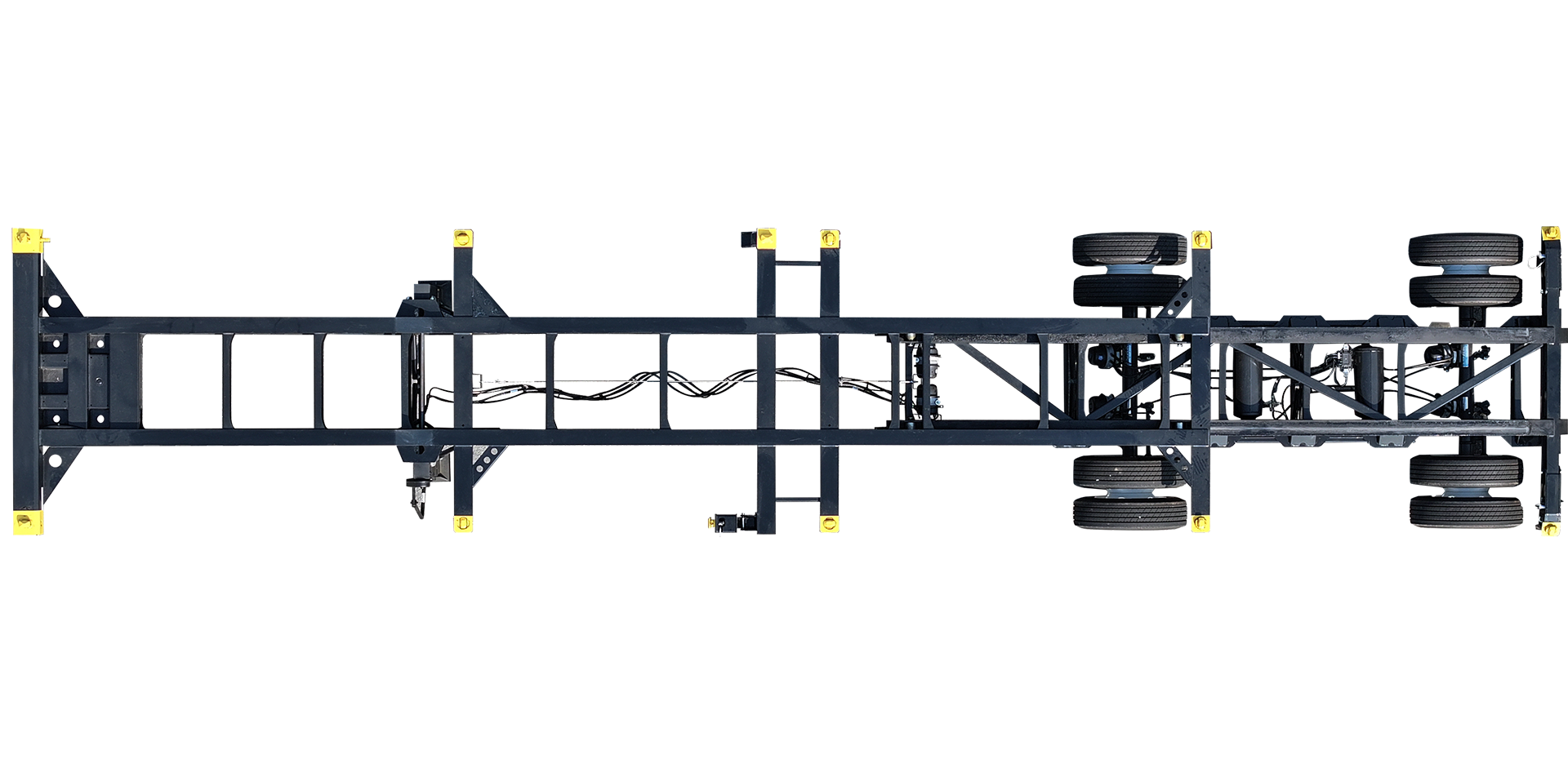

Overall Length: 31’-7” (retracted) or 40’-11” (extended)

Overall Width: 96”

Fifth Wheel Height: 47 ± 1”

Rear Deck Height: 48 ± 1”

Kingpin Location: 18” (From the rear of the front bolster)

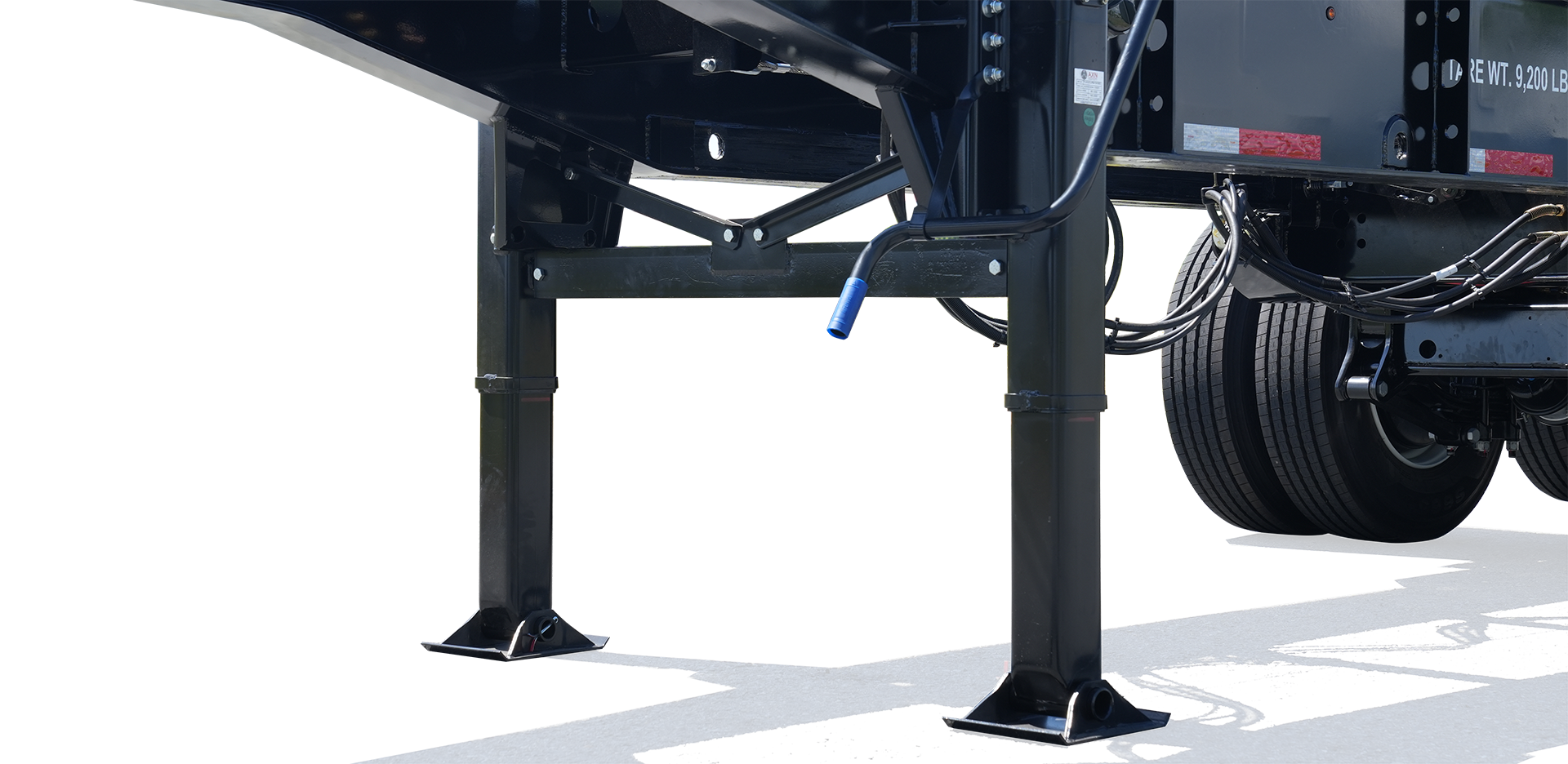

Landing Gear Location: 100” (From the kingpin center)

Tandem location: 32” (From rear face of rear bolster to rear axles center when extended)

Axle Spread: 109”

Tare Weight: 9,350 lbs ± 3%

Payload: 54,500 lbs for 20’ loaded or 57,000 lbs for 40’ loaded

Color on request

-

Specifications

- Warranty Policy

| Main beam | 16″x5” fabricated I-beam with high strength flanges and 6-11/32” height for gooseneck rail. ASTM Grade 130. |

| Upper coupler | 5/16” pick up plate with 2” diameter square type kingpin per SAE standard, 380-420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Front Bolster | Fabricated bolster assembly with high strength plates with 89” centers, equipped with none retractable twist locks. |

| Intermediate Bolster | Fabricated with retractable twistlocks with swing down twistlocks. |

| Rear Bolster | Tapered rectangle bolster of the main frame fabricated by 3/8” thick top and bottom plate with 5/16” thick side plates. 6-5/8” height x 4” wide fabricated box beam bolster on slider composed by1/2” thick top/bottom plates with 5/16” thick side plates with flip up twistlocks. |

| Slider beam | Fabricated I beam with 3/4″x5” upper and lower flanges and 3/16” web, slider extends or retract on 6” diameter steel rollers. |

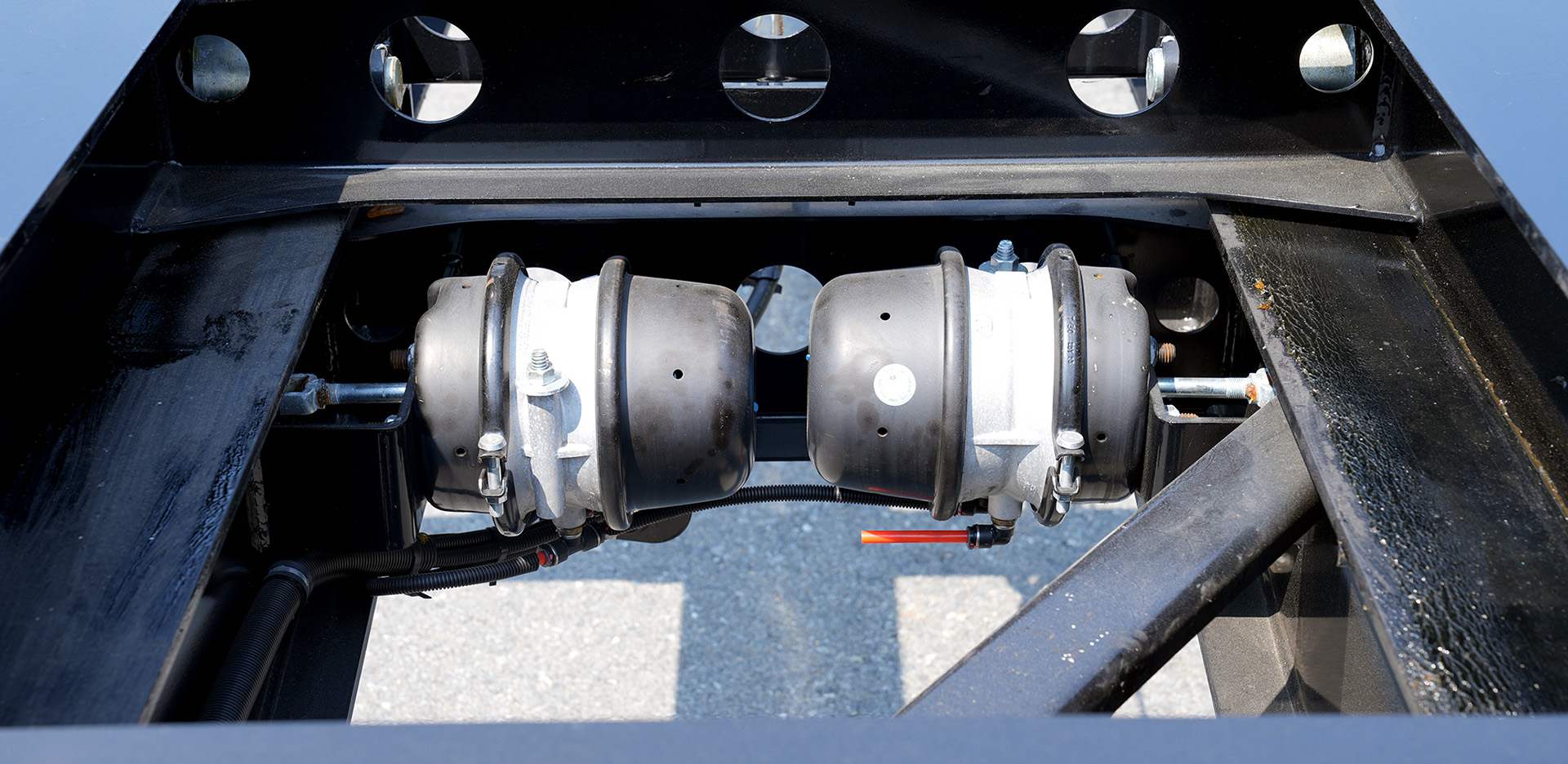

| Locking system | Air operated locking pins, activated by Goldseal 30/30 spring brakes on both sides of the trailer through third gladhand on front sill. |

| Landing Gear | 65,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Landing gear brackets are bolted on the main beam as the layout. |

| Container locks | Provided. |

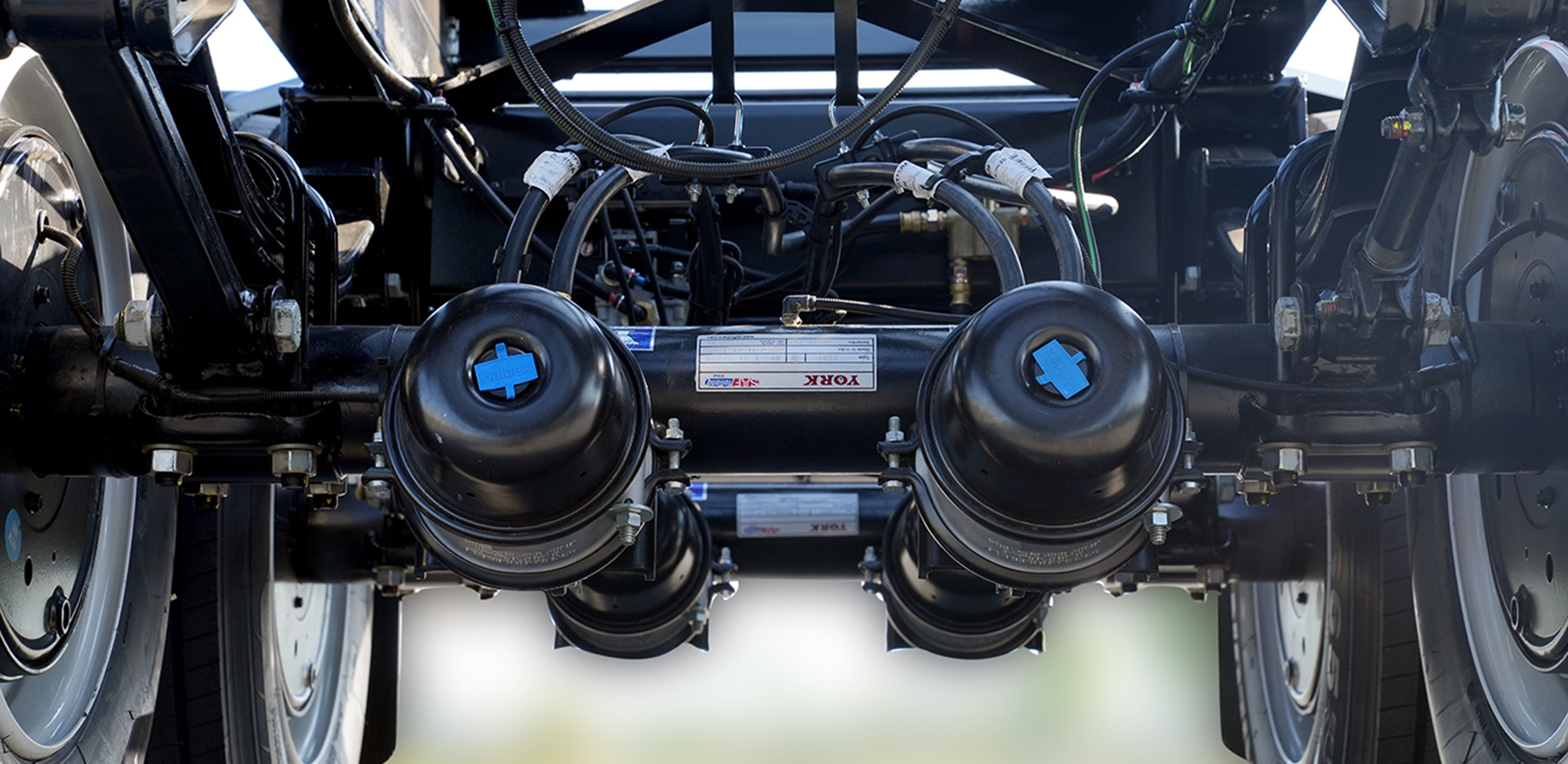

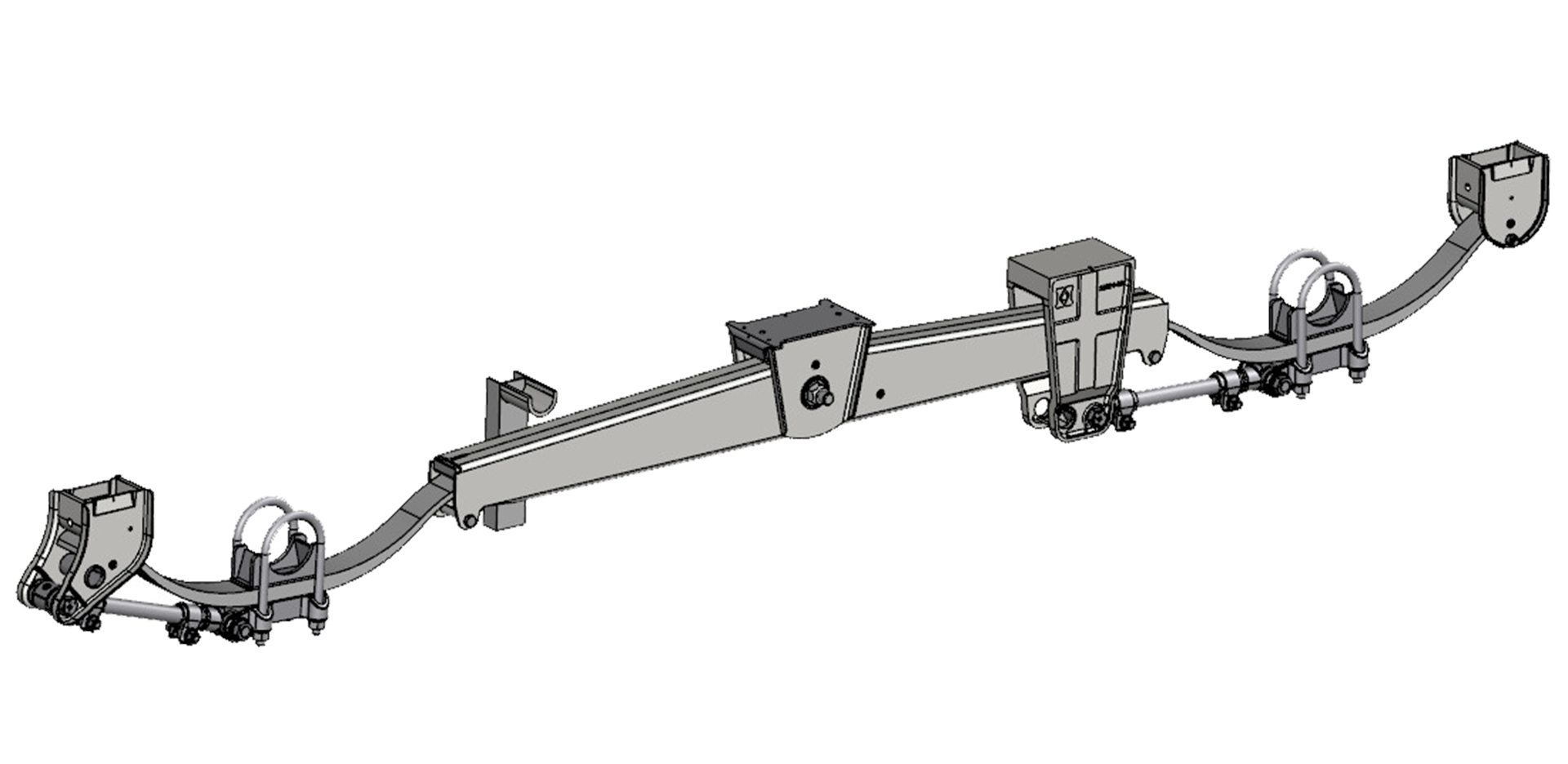

| Suspension | 109″ axle spread, underslung configuration with high-arch single spring (360-00). |

| Axles |

|

| Wheel end | Hub & Drum Assembly. 340-4370 solid Aluminum Grease hub cap. Seals P/N Scotseal plus XL 46300. Bearings. Spindle nut Double Nut. |

| Lubricant | Synthetic Semi-fluid grease lubricant. |

| Wheels | 22.5 x 8.25 10-stud hub-piloted wheels with 5 hand holes and with TR572 valve stem. |

| Tires | 255/70R22.5-16PR tubeless type. |

| Brake System | 110800 spring brake priority valve system and 2S/1M ABS system. Glad hand 12-0061 and 12-0081. 3/8” blue air tube for control and 3/8” red for supply. Goldseal T30/30, 2.5” stroke brake chamber. THACO CMC (Vietnam) air tanks. |

| Electrical | Mold seal wiring harness, Reserved PSI and GPS connector. LED lights (amp connections for S/T/T lights and .180 bullets for others). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | 16-724 plastic material with split pins. |

| Document Holder | THACO Plastic Components (Vietnam). Installed on roadside near crank handle. |

| Conspicuity tape | Installed per federal regulations. |

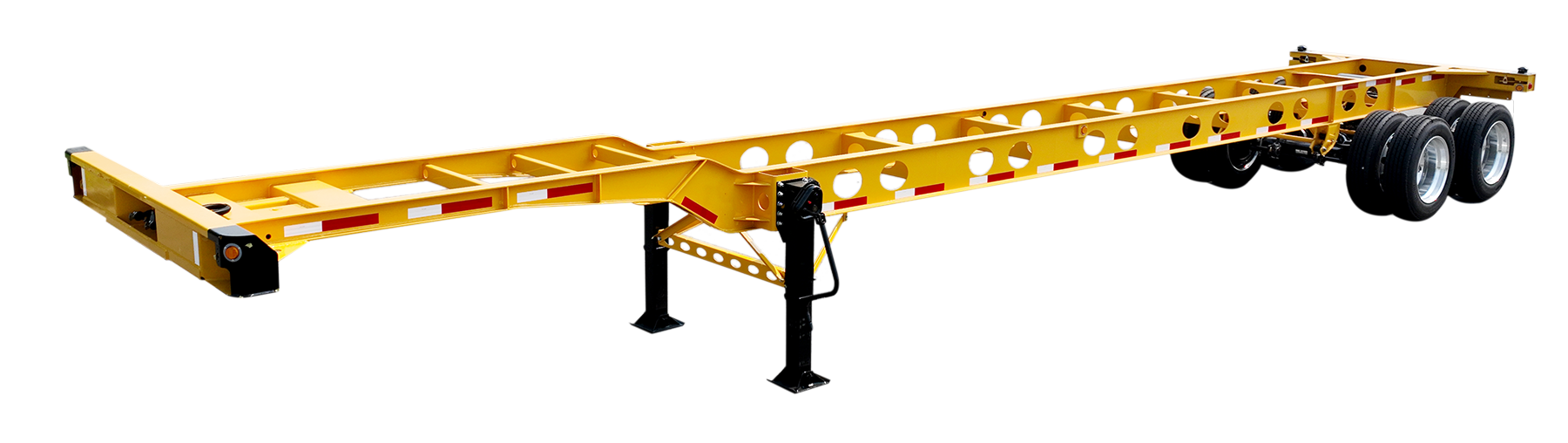

| Painting | Abrasive blast of all metal surfaces – not less than SA-2.5 to achieve clean bare steel. Surface will be coated with electrophoresis primer and powder topcoat. Total thickness not less than 80μm after dry membrane. Coating supplier PPG (Vietnam). |

| Marking | Customer configuration (includes Decal, layout, VIN, nameplate). |

| Hubodometer | NONE |

| Tire Inflation System | PSI (USA) Tire Inflation System with THERMalert. |

| Mud flaps | THACO Plastic Components (Vietnam) 18”x24”x1/4” white PVC mud flaps with “CUSTOMER” logo. |

Advanced Features of 20’/40′ Combo Tandem

Electrical and Lighting Systems

The 20’/40′ Combo Tandem Chassis is equipped with a premium PHILLIPS (Mexico) mold-sealed wiring harness, which effectively protects the wiring from environmental factors and potential damage. Additionally, it features OPTRONICS (Taiwan) LED lights, specifically designed to resist theft and withstand harsh conditions.

Innovative Air System

The 20’/40’ Combo Tandem is equipped with an air-operated locking pin system, activated by HALDEX (Mexico) Goldseal 30/30 spring brakes. This system ensures that the trailer stays securely connected to the tractor, preventing accidental disconnection and contributing to the chassis’s safety and stability during operations.

Maintenance and Serviceability

Ease of Maintenance

The Tandem Combo Chassis is designed with serviceability in mind. The lock system, axles, and suspension components are all engineered for easy maintenance and repair. The pre-painted steel components are resistant to corrosion, reducing the frequency of maintenance work and extending the operational lifespan of the chassis.

Spare Parts and Warranty

Many of the components, such as the STEMCO wheel ends and Haldex brake chambers, come with multi-year warranties, providing peace of mind for operators. Additionally, spare parts are readily available from local suppliers, ensuring minimal downtime and efficient repairs when needed.

Conspicuity and Safety Markings

The 20’/40′ Combo Tandem features 3M conspicuity tape installed in compliance with federal regulations, enhancing visibility and safety on the road. Additionally, custom markings and decals can be applied as per client specifications, ensuring branding and clear identification of the chassis in transportation fleets.

| No. | Part Name | Manufacturers Name | Time | Warranty Information |

| 1 | Frame | Thaco Trailers | 5 Years | THACO INDUSTRIES TRAILERS AND HEAVY STEEL STRUCTURES MANUFACTURING LIMITED LIABILITY COMPANY Add: Chu Lai IZ., Nui Thanh Commune, Da Nang City, Vietnam Office: (+84) 2353.565.327 Website: https://thacotrailers.com/ |

| 2 | Paint(ED + Top coat) | PPG | Painting: 7 Years |