THE ADVANTAGES OF LOWBOY TRAILERS FOR HEAVY LOADS

A lowboy trailer is a commercial semi-trailer that commonly features fixed necks, goosenecks, and removable goosenecks (RGN). Lowboys sit low to the ground and are used to haul heavy equipment such as bulldozers and large industrial equipment. In this in-depth guide, Thaco Trailers will help you explore everything about lowboy trailers, from their unique designs and the advantages of lowboy trailers to the different types available to help you select the best fit for your needs.

1. What is a lowboy trailer?

1.1 Definition

Lowboy, also called low beds, double drops, floaters, and low loaders depending on the region, is a type of heavy-duty flatbed trailer characterized by its low deck height, designed specifically for hauling tall and heavy loads of items that would be too high to transport on standard trailers. The first drop occurs immediately after the gooseneck, and the second drop is located before the wheels, enhancing stability. Its unique design includes a lowered platform between the front and rear axles, which enhances stability and allows for the transportation of large, heavy equipment like bulldozers, cranes, and industrial machinery.

Lowboy trailers require a truck to tow them. They have hydraulic systems that lift the trailer for engagement after loading and air brakes for slowing down and stopping. These are made of aluminum or high-strength steel to sustain superimposed loads and can be 2 to 8 axles in number in aspects of weight and size of the load they are supposed to carry.

Read more: What is a lowboy gooseneck trailer? A comprehensive guide

1.2 Dimensions

The dimensions of a lowboy trailer can vary, with an overall length of approximately 24 to 29.5ft and an overall width of up to 8.5ft maximum, while the deck height may stand in the range of 18-24 inches. These trailers may provide specific weight capabilities of 40,000 pounds with two axles and anywhere from 80,000 pounds and up for more axles depending on design, specifications, and laws.

- Lowboy trailer length: 24 ft to 29.6 ft.

- Lowboy trailer height (well): 18 to 24 inches

- Standard lowboy trailer height from the ground: 18 inches

- Lowboy trailer freight height: 11.5 ft to 12 ft.

- Lowboy trailer width: 8.5 ft maximum.

2. The advantages of a lowboy trailer for heavy loads

2.1 Enhanced load capacity and flexibility

Lowboy trailers are designed to transport exceptionally heavy cargo, such as construction machinery, industrial equipment, and large components for infrastructure projects. Their low deck height provides additional vertical clearance, making them ideal for transporting tall items that standard trailers cannot accommodate. Additionally, with a load capacity ranging from 40,000 to 80,000 pounds or more, these trailers can handle demanding hauling needs and offer the versatility to transport a wide variety of heavy cargo.

2.2 Improved stability and maneuverability

Lowboy trailers’ low deck height and double-drop deck design offer enhanced stability by lowering the center of gravity, ensuring safe transport of heavy or large cargo. This stability is crucial when navigating through tight spaces, uneven terrain, or when making sharp turns, which can be challenging for other types of trailers.

2.3 Easy loading and unloading

Lowboy trailers can transport heavy cargo and wide loads. Industrial and construction equipment, which are often unusually wide, can be easily accommodated. Depending on the model, lowboy trailers can be equipped with detachable or folding goosenecks, allowing the front of the trailer to be removed and creating a ramp for the cargo. This feature simplifies the process, especially when loading items that are too heavy to be lifted by cranes or forklifts, ensuring a smoother and safer operation.

Read more: What is a shipping container chassis? Types and uses explained

2.4 Height clearance for bridges and overpasses

The low deck height of a lowboy trailer offers increased vertical clearance, making it ideal for transporting tall items under bridges and overpasses, thereby reducing the risk of collisions. This feature is crucial for safely transporting equipment that exceeds the height limits of standard trailers, ensuring both compliance with road regulations and the avoidance of potential obstacles.

2.5 Cost efficiency

While the initial cost of using a lowboy trailer might be higher due to the specialized nature of the equipment, the long-term benefits make it a cost-efficient solution for heavy haul transportation. The ability to transport large and heavy items in a single trip reduces the need for multiple shipments, saving on fuel and labor costs. Additionally, the trailer’s durability and ability to handle various loads make it a reliable investment for companies that regularly transport heavy or large cargo.

3. Common types of lowboy trailers

The following information, summarized from industry-wide trends, provides an overview of the various structures and configurations of lowboy trailers, which are designed for transporting heavy loads. Understanding these options enables businesses to choose the most suitable trailers for their logistics needs.

3.1 Structure

- Fixed-Neck Lowboy

This type of lowboy trailer has a fixed neck, making it more rigid but also limiting its versatility in loading options. It’s often used for transporting loads that do not require detaching the trailer bed and is suitable for those who frequently carry cargo on flatbeds

- Removable-Neck Lowboy

Also known as RGN (Removable Gooseneck) lowboys, these trailers allow the neck to be detached, exposing an entry ramp, and making it easier to load heavy machinery or vehicles from the front. This flexibility is especially useful for large or awkwardly shaped loads and is the perfect choice for the transporting of construction vehicles to and from construction areas.

- Extendable Lowboy

These trailers can be extended to accommodate longer loads, providing additional length as needed. They are ideal for transporting extremely long equipment or machinery that would not fit on a standard lowboy trailer. These trailers can be retracted to increase maneuverability when carrying shorter loads or when no cargo is being transported.

- Double Drop Lowboy

Featuring two drops in deck height, one after the gooseneck and another before the wheels, this type of lowboy is perfect for transporting tall loads while maintaining a low center of gravity. With the least amount of ground clearance on the deck, this type of lowboy allows transportation of large loads such as specialized construction equipment and vehicles, other types of machinery, or wind turbines, keeping the cargo low to the ground to ensure their safe transportation.

Read more: What are the different types of semi-trailers?

3.2 Size and Axle

- Single-Axle Lowboy

These trailers are designed for lighter loads, typically under 25 tons. They offer better maneuverability in tight spaces but are limited in their load capacity. The lighter weight also improves fuel economy, while reducing maintenance costs due to simpler componentry.

- Dual-Axle Lowboy

With two axles, these lowboys can handle heavier loads, usually up to 40 tons. They offer a balance between capacity and maneuverability. This is the most common axle configuration as its balanced nature accommodates most cargo types.

- Tri-Axle Lowboy

Tri-axle lowboys are suited for even heavier loads, often supporting up to 60 tons. The additional axle improves weight distribution and stability.

- Multi-Axle Lowboy

Multi-axle lowboys can be customized with four or more axles for the heaviest and largest loads. These trailers are essential for transporting exceptionally large and heavy equipment, such as industrial machinery or large construction vehicles.

Read more: The ultimate guide to selecting tri-axle chassis for your semi-trailer

4. How to choose the right lowboy trailers for heavy loads?

Choosing a suitable lowboy trailer for the transportation of big cargo requires meticulous evaluation of several criteria. Let Thaco Trailers assist you in selecting the trailer that optimizes efficiency and safety by assessing your particular transportation requirements.

- Evaluate Load Dimensions and Mass: Commence by ascertaining the size and mass of the cargo to be conveyed. The lowboy trailer must be selected according to the suitable dimensions and axle arrangement to support the weight.

- Evaluate Maneuverability Specifications: For transportation in metropolitan areas or places with narrow turns, a trailer with enhanced maneuverability, such as a single-axle or dual-axle lowboy, may be advantageous.

- Assess Terrain and Road Conditions: The terrain and road conditions you may encounter affect your decision. For example, uneven terrain or dirt roads may need a trailer with improved stability and weight distribution, such as a tri-axle or multi-axle lowboy. Some individuals may also benefit from a spread axle layout, which facilitates improved stability and weight distribution. Height restriction on routes that require traversing under bridges or overpasses should also be taken into consideration. A lowboy trailer with a reduced deck height, such as a double drop lowboy, may be essential to provide enough clearance.

- Loading and Unloading Requirements: If your cargo presents challenges for loading or unloading, or is incompatible with an overhead crane, a removable-neck lowboy trailer may be the optimal choice, facilitating simpler front-end loading. Construction trucks may autonomously load into a disconnected, lowered RGN lowboy trailer, therefore reducing loading time and enhancing transportation efficiency.

- Financial Considerations: Multi-axle lowboys provide more capacity but entail elevated expenses. Align your budget with operational requirements to choose the most economical option.

Read more: Understanding the 20ft container chassis: Dimensions and benefits

5. The main differences between lowboy and flatbed semi-trailers

|

Lowboy Trailers |

Flatbed Semi-trailers |

|

| Definition | A lowboy or low bed trailer is a type of heavy-duty flatbed trailer that features low deck height due to the bed structure dropping lower than usual between the axles and the gooseneck. | A flatbed trailer is a type of semi-trailer that has a flat platform for carrying payloads that cannot be put within a confined container, and can be laid flat on an even surface. |

|

Physical Structure |

Consist of a large gooseneck that facilitates coupling, then significantly drops in height to provide a bed platform that is low to the ground. | Often consists of a flatbed to carry cargo with no drop from the coupler to the end of the trailer. May also have a minor gooseneck to provide better bed platform balance. |

| Capacity for Freight Load |

The payload capacity of a lowboy trailer varies depending on the model and carrying capacity. Conventional two-axle lowboy trailers generally weigh 15,000 pounds to 18,000 pounds and have a maximum payload capacity of 40,000 pounds. Adding axles can boost the payload capacity to 80,000 pounds. |

Their payload capacity depends on the design, construction materials, and additional features. Standard flatbed trailers weigh 6,000 pounds to 12,000 pounds on average and can haul freights of up to 48,000 pounds. |

| Types of Freight | Large equipment and machinery, construction vehicles, specialized equipment (wind turbines, etc.) | Compact, stackable cargo such as construction materials and equipment (steel pipes, lumbers, steel coil, etc.) |

Read more: Extendable Chassis: Key Features and Applications in the US

6. Why you should choose Thaco Trailers products for heavy equipment transport

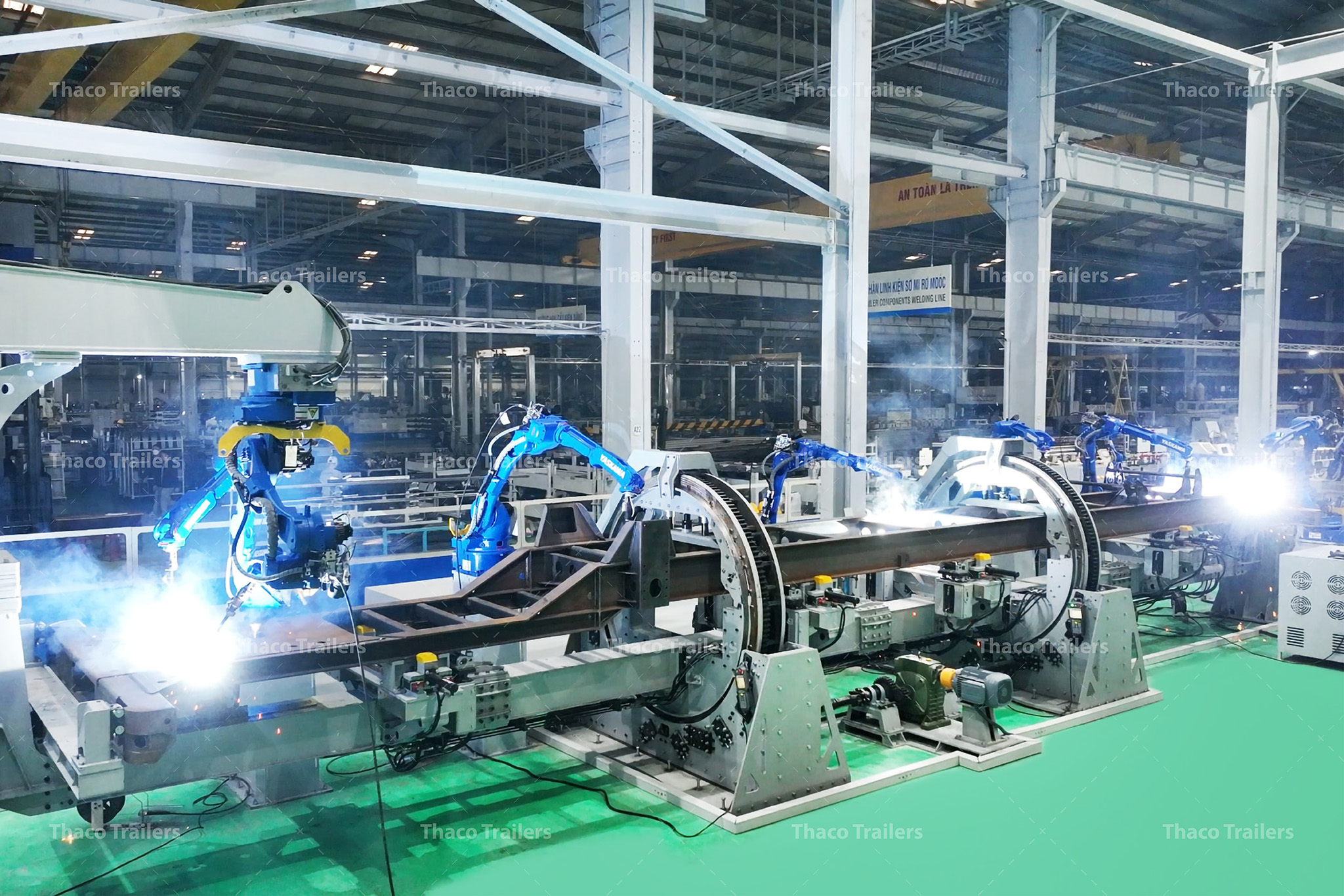

Thaco Trailers differentiates itself in the market by providing trailers specifically designed for the transportation of heavy equipment, constructed to the highest international standards. These trailers are constructed with materials and components that comply with JIS (Japanese Industrial Standards), ASTM (American Society for Testing and Materials), Federal Motor Vehicle Safety Standards (FMVSS), and the Department of Transportation (DOT) regulations, guaranteeing exceptional quality and endurance. The firm procures components and supplies from premier worldwide suppliers such as MAANSHAN Steel, POSCO, AXN, SAF HOLLAND, TECTRAN, and YORK, guaranteeing the dependability and durability of each trailer.

Thaco Trailers employs a sophisticated SCADA production system for effective data management and quality assurance in manufacturing processes. Thaco Trailers has an annual production capacity of 30,000 units and adheres to ISO 9001:2015 and ISO 14001:2015 standards, emphasizing continual development, innovation, and customization to fulfill client requirements.

Building on this foundation, Thaco Trailers offers an extensive range of shipping container chassis, including intermodal chassis (slider, extendable, and standard), specialized semi-trailers, and OEM specialized semi-trailer components. Customization options are also available to address specific transportation needs, ensuring enhanced safety, compliance with international standards, and cost-effective, reliable solutions for every operation.

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn