HOW TO CHOOSE THE RIGHT 40FT CONTAINER CHASSIS FOR LOGISTICS NEEDS

A 40ft container chassis plays a vital role in the logistics ecosystem, acting as a cornerstone for operational proficiency, expense management, and safety within intermodal transport. Choosing the appropriate chassis is key to streamlining supply chain processes, mitigating potential hazards, and guaranteeing the dependable and punctual delivery of cargo.

1. Understanding the basics of 40ft container chassis

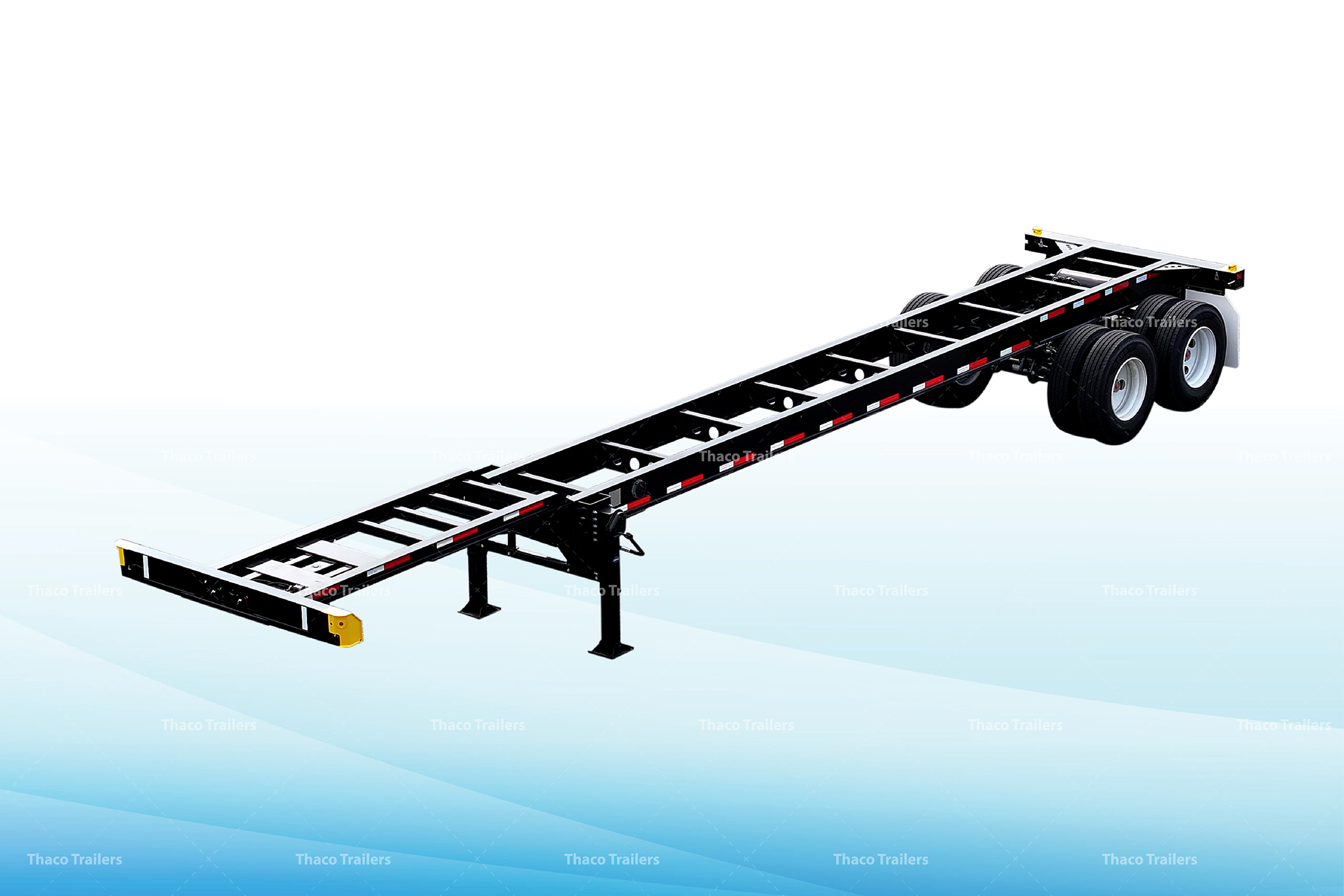

1.1 What is a 40ft container chassis?

A 40ft container chassis is a special type of trailer used for moving 40-foot shipping containers chassis. This kind of chassis presents an integral constituent in the intermodal movement of cargo, as it avails easy loading, transportation, and unloading of goods from ports, warehouses, or any other logistics facilities. In summary, it provides one with a rigid and reliable chassis that empowers the business to strongly move oversized cargo without jeopardizing the issue of safety.

>> Read more: Exploring Lightweight Chassis for Modern Logistics – Thaco Trailers

1.2 Key Components of a 40ft Container Chassis

- Frame: The frame represents the backbone of the chassis and is usually made of high-strength steel that supports the weight of the container for structural integrity. Some 40ft chassis are designed with a gooseneck to perfectly fit into the gooseneck groove of the container, which not only reduces weight but also securely fixes the container during transportation.

- Axles: Container chassis axles are relevant horizontal shafts that support the weight of the container, thus distributing the load uniformly for stability during transportation. Typically located toward the rear of the chassis, they connect to the wheels, suspension and braking systems, supporting the safe movement and legal weight distribution.

- Twist Locks: Twist locks are mechanisms provided in the chassis, distributed over the chassis, to tie up the containers to ensure they remain steady during goods transportation. Their number and position depend on how many and what size of containers are being carried, like two 20ft containers chassis, one 40ft, or just a single 20ft container on a 40ft chassis. The operation of the twist locks could therefore be either manual or automatic, depending on the chassis design.

- Wheels and Tires: The wheels are mental circular structures mounted to the axles, providing the base for the tires and enabling the chassis to roll and move. They support the weight of the container and come as singles or doubles to ensure stability and proper load distribution. Tires are the rubber components fitted over wheels for the purpose of providing grip, cushioning, and smooth riding while supporting the load during transport.

- Suspension System: The suspension system absorbs road shocks and vibration to the chassis and container cargo. It also assists in stability maintenance, most especially on uneven grounds.

- Brake System: Most 40ft chassis apply air brakes, which are powerful and reliable in carrying a heavily loaded container. Most modern chassis installed with ABS avoid wheel lock-up during braking; this is especially so under adverse weather conditions, thus boosting safety.

>> Read more: Essential Parts of Trailer Suspension System – Thaco Trailers

2. Factors to Consider When Choosing a 40ft Container Chassis

Choosing the right 40ft container chassis requires profound knowledge of your logistics. Considering all of the following elements, you will make certain that the chosen chassis will answer not only your present needs but will also ensure efficiency and fuel economy.

2.1 Payload Capacity

Payload capacity, on the other hand, refers to the maximum weight that the chassis can be able to carry; as such, payload capacity is relevant in the selection of a 40ft container chassis. It is a proper way of selecting the chassis by considering the average and peak cargo weights experienced in the operation, whereby the chassis would be able to meet the demand with some buffer for sudden spikes in the load. If your operations involve moving various types of cargo, choosing a chassis that is correctly sized for the payload will let you handle different loads without having to purchase multiple specialized trailers.

2.2 Material and Durability

Material variety used in the manufacture of the chassis plays a vital role in the durability of the product, as it will directly affect service life, safety, cost-effectiveness, and overall performance. Quality steel with corresponding ASTM standards, like ASTM A36 for structural steel, offers the required tensile strength and resistance to corrosion for a strong and reliable chassis. These standards evaluate properties of steels such as its thickness, dimensional tolerances, and mechanical performance, ensuring the chassis can withstand the demands of transport and harsh conditions like saltwater and extreme temperatures.

However, acquiring such high-quality material has sometimes been a problem with many manufacturing enterprises since they have to strike a balance between compliance with ASTM standards and achieving cost efficiency with good production volume. A chassis made of durable ASTM-accomplished steel reduces costs in maintaining and repairing. Above all, your needs will provide a transport solution which is safe and long-lasting, and in that investment, will be warranted over time.

>> Read more:

- What Is a Lowboy Gooseneck Trailer? A Comprehensive Guide

- The Advantages of Lowboy Trailers for Heavy Loads – Thaco Trailers

2.3 Compliance and Regulations

The FMCSA has strict safety requirements on the providers of intermodal equipment; it systematically inspects, maintains, and repairs 40ft container chassis. To be in compliance, the equipment must be identified with a USDOT number, which would accurately identify that unit and provide its safety records to maintain standards. Secondly, the FMCSA adopts requirements that are very strict over cargo securement so that containers are well secured at the time of transportation not only to protect the cargo but also to protect the public.

Using non-compliant chassis puts drivers in higher danger of accidents, leading to further liabilities against the law and damages to house reputation. Because providers will understand these regulations and apply their teaching, they are able to make sure that the 40ft container chassis not only meets the safety and operational standards but also avoids the financial and legal pivots which arise with any level of non-compliance.

>> Read more: What is a dry van trailer? Learn about types and uses – Thaco Trailers

2.4 Compatibility with Transport Vehicles

The chassis must be compatible with the transport vehicles in your fleet, which includes checking the hitch types, axle configurations, and overall dimensions to ensure a seamless connection and transport process. Incompatible chassis can cause violations of traffic regulations or obstacles during loading or unloading, especially if additional equipment or manual adjustments are required to make the chassis fit properly with the tractor or loading systems.

Proper compatibility with the tri-axle chassis helps maintain a stable connection during transit, reducing risks of trailer sway, detachment, or imbalance. Additionally, the chassis braking system should be compatible with the vehicle’s air or hydraulic brake systems, as proper integration ensures reliable braking performance and control for safe travel on the road.

2.5 Additional Features

The container chassis can be installed with several other features in order to make it more workable and safe. An adjustable chassis allows for transportation to be done for both 20ft and 40ft containers, while ABS improves control during braking in heavy loads. Other features of air suspension provide smoother transport and better load distribution compared to conventional systems.

3. Types of 40ft Container Chassis and Their Applications

Different types of 40ft container chassis are available in the market, each tailored to specific applications. Gaining an understanding of these options will enable you to select the most suitable one for your requirements.

3.1 Standard Container Chassis

The simple, lighter type of trailer is a standard container chassis. For the on-road carriage of intermodal containers, especially the standard 40ft containers, it is used. It consists of a simple, sturdy, lightweight frame able to carry heavy loads and hence suitable for general cargo transport. This kind of chassis is so common in intermodal transport because it is economical and easy to use.

These chassis are cheaper to buy and maintain, being simpler and standardized, which is just perfect for a company looking to maximize its logistics costs. Standard container chassis contribute to minimizing downtimes in logistics operations, hence speedy turnarounds, because of the ease of their availability and use.

3.2 Extendable Container Chassis

The Extendable Container Chassis, also termed a telescopic chassis, is a particular type of trailer used to carry containers of various lengths. Contrary to the usual chassis, which is fixed in size, this extendable chassis will be able to adjust to various lengths of containers, hence allowing more versatility and flexibility during container transportation.

This reduces the need for several chassis and allows for quick adjustments; hence, it provides a cost-effective and flexible solution to various logistics needs of long haul, intermodal transport, and diverse cargo handling. Carriers can move various container sizes with the same chassis to maximize equipment utilization and in turn drive higher returns on investment and reduce operation costs.

3.3 Slider Container Chassis

A slider chassis is a special kind of trailer designed with an adjustable axle system. The axle system allows the wheels in the rear to slide along the chassis frame, offering flexibility in distributing the weight of the container for better handling and compliance with legal limits on axle weight. Slider chassis are generally used in the transportation of intermodal containers, mainly for regions whose road regulations differ as to axle weight distribution.

With heavy loads, this operationally allows for fine adjustments of axle positioning to optimize load distribution with the aim of ensuring safety and compliance, especially on routes over long distances. Slider chassis are also suitable for the transportation of high-cube containers, which are taller and may have different weight distribution problems compared to the standard ones.

>> Read more: The ultimate guide to selecting tri-axle chassis for semi-trailer – Thaco Trailers

4. Factors to Consider When Operating the 40ft Container Chassis

Operations of a 40ft container chassis require great concern for capacity management, vehicle maintenance, regulatory compliance, and safe driving practices. Given these factors, logistics operators will be able to provide safe and efficient transport of containers at competitively cheaper costs while ensuring the mitigation of different kinds of exposure to critical surges in operational efficiency.

Proper capacity management is essential for maintaining the stability and safety of the container during transit as the well-distributed cargo helps the vehicle operate smoothly and prevent unnecessary risks. Additionally, regular preventive maintenance of brakes, tires, and lights is vital to keep the chassis in optimal working condition and enhance the safety. Finally, safe driving practices are essential for preventing risks, especially when operating large vehicles like a 40ft container chassis, as any collision can result in severe damage.

>> Read more: The Benefits of Using a 40ft Chassis in Freight Transportation – Thaco Trailers

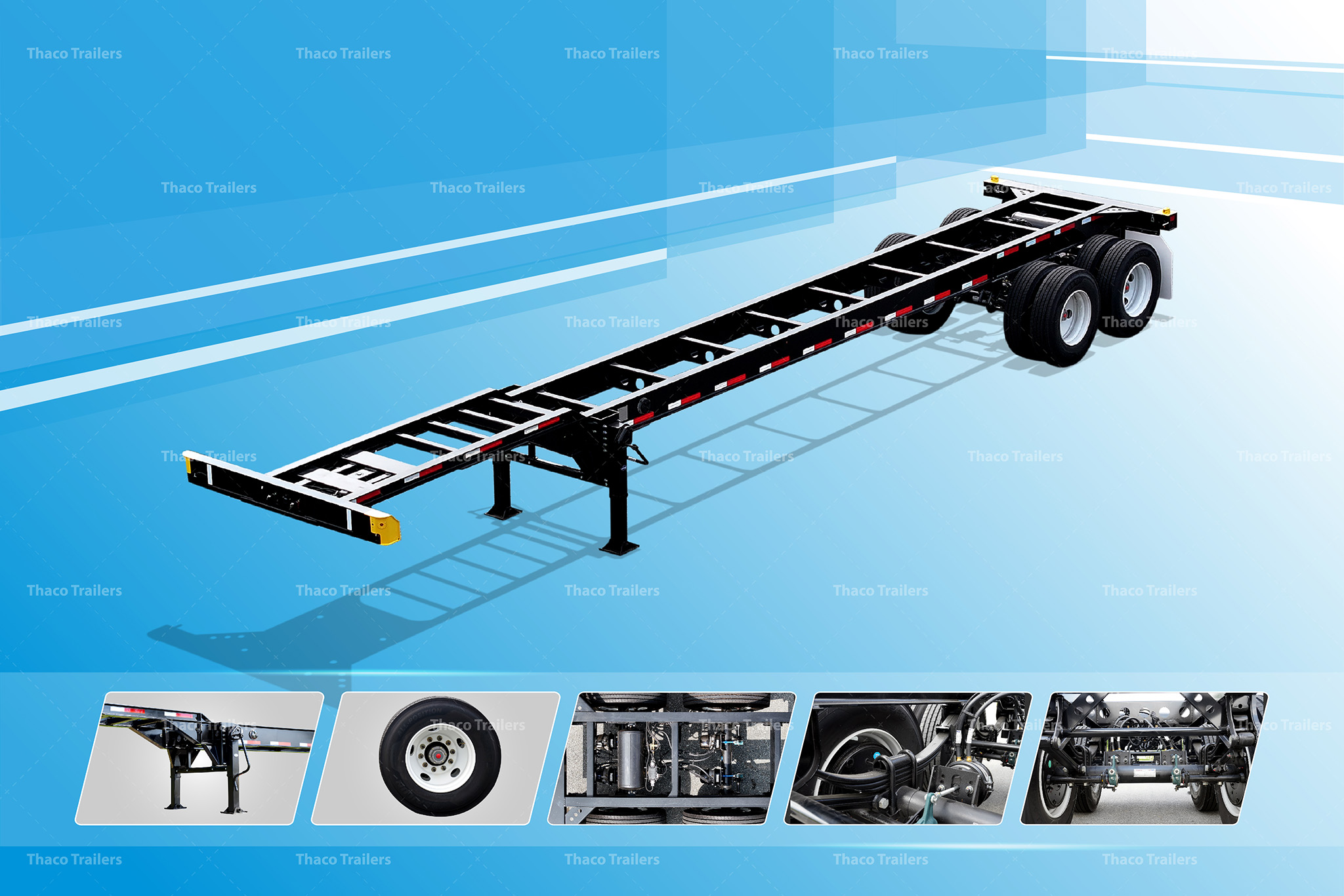

5. Why choose the Thaco Trailers’ 40ft Container Chassis?

Since choosing the right 40ft container chassis is an important decision for any logistics provider, at Thaco Trailers, we pride ourselves on the leading semi-trailers manufacturing company that strictly meets North American standards while offering top-class 40ft container chassis through advanced technology and excellence in manufacturing. With modern machinery such as fiber laser cutting machines, CNC brake press machines, and automatic welding robots, each chassis produced by Thaco Trailers goes through the highest level of precision and durability. The SCADA production management system further enhances efficiency and quality control throughout the production process.

A major benefit for logistics companies choosing Thaco Trailers is the customization flexibility. The company offers tailored solutions to meet specific customer needs, ensuring that every chassis can be modified to suit unique operational requirements. The production process, with an annual capacity of 30,000 units, is designed for efficiency and responsiveness, providing a high volume of customized products without sacrificing quality.

Thaco Trailers ensures seamless delivery through its comprehensive logistics services, which are backed by international experience and compliance. With over 16,100 square meters of production facilities and four main production lines, Thaco Trailers leverages its modern processes and high-tech machinery to produce container chassis that not only meet but exceed the standards and performance benchmarks of global competitors like CIE, Panus USA LLC, Manac Inc, and Randon. Choosing Thaco Trailers means investing in a chassis that is high-performing, reliable, and manufactured with world-class standards and technologies.

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn

>> Read more: What is a genset chassis? Application and How it works – Thaco Trailers