SEMI-TRAILER WEIGHT CAPACITY: CHOOSING THE BEST OPTION

When selecting a semi-trailer, one of the most important considerations is its weight capacity. Choosing the correct weight capacity optimizes operational efficiency, minimizes damage risks, and ensures transportation safety. In this article, Thaco Trailers guides you through selecting a semi-trailer with the appropriate weight capacity, along with key factors to consider when making an informed decision for your logistics operations.

Understanding the importance of semi-trailer weight capacity

Understanding your trailer’s weight capacity is essential for safe, efficient operations. Exceeding this limit can damage the trailer and towing vehicle, leading to increasing wear and safety hazards. Proper weight management allows you to carry maximum payloads within legal limits while maintaining vehicle stability. It also reduces fuel consumption, minimizes maintenance costs, and extends fleet lifespan, making your logistics operations more cost-effective and sustainable.

How much weight can each trailer type haul?

Flatbed Trailers

Flatbed trailers are versatile, typically offering payload capacities between 42,000 and 48,000 pounds. They are ideal for transporting oversized, heavy, or irregularly shaped cargo such as construction materials, vehicles, and machinery. The absence of sides and a roof enables loading from any angle, providing flexibility in operations. The trailer’s payload capacity depends on its structural design, axle type, and material strength.

Lowboy Trailers

Lowboy trailers are designed for transporting oversized equipment, with payload capacities reaching up to 80,000 pounds or more. Their low-deck construction allows for the transport of tall machinery while remaining within height restrictions. The low center of gravity enhances stability, making them suitable for construction, industrial, and heavy-haul applications.

Refrigerated Trailers (Reefers)

Refrigerated trailers, or reefers, are used to transport temperature-sensitive cargo and generally support 40,000 to 45,000 pounds. Actual payload varies depending on the insulation, refrigeration unit, and trailer design. When calculating load capacity, include the weight of refrigeration equipment and fittings to avoid exceeding limits.

Drop Deck Trailers

Drop deck trailers accommodate tall loads such as construction equipment and industrial machinery. With capacities ranging from 40,000 to 45,000 pounds, they feature a lower deck height, enhancing load stability and ease of loading. Their design supports cargo that exceeds the height limits of standard flatbeds.

Tanker Trailers

Tanker trailers transport liquids and gases and typically carry between 40,000 and 50,000 pounds. Capacity depends on the liquid type, trailer design, and axle count. Balanced weight distribution is critical to avoid instability, especially when transporting shifting fluids. Proper loading is essential for safety and legal compliance.

These payload ranges are general estimates. Trailer payload capacity varies by configuration, materials, axle count, and manufacturer. Always consult official specifications to confirm the exact allowable payload.

Factors affecting semi-trailer weight capacity

Trailer material and construction

The semi-trailer materials significantly influence weight capacity and structural durability.

- Steel: Known for strength and durability, steel trailers handle heavy-duty applications but add more tare weight, reducing payload efficiency. They are ideal for rugged, high-load environments.

- Aluminum: Aluminum trailers are lightweight, allowing for higher payloads and reduced fuel costs. However, they offer lower structural strength, making them less suitable for heavy or abrasive cargo.

- Composite Materials: Composite materials balance strength and reduced weight but often come at a higher cost. They require specialized maintenance and are increasingly adopted in advanced trailer models.

In addition to material, the quality of manufacturing impacts overall strength. Precision welding, proper reinforcement, and structural integrity are critical for safe, long-term performance under heavy loads.

Number of axles and load distribution

The number of axles on a semi-trailer significantly impacts its weight capacity and load distribution. Each axle helps to distribute the weight of the cargo evenly across the trailer, ensuring that the load is stable during transport.

- Dual-Axle Trailers: Suitable for light to moderate loads, dual-axle trailers typically support up to 10,000 pounds. However, they offer limited surface area for weight distribution.

- Tri-Axle Trailers: These trailers distribute load more effectively, increasing capacity and reducing strain on suspension and tires.

- Additional Axles: Quad or more axles support extremely heavy loads and help meet road-specific weight distribution regulations. They are often used for specialized industrial equipment or construction machinery.

Proper load distribution is also essential to avoid heavy load on any one axle, as excessive weight on a single axle can lead to damage, legal penalties, and safety issues. Ensuring the load is evenly distributed across all axles helps maintain stability and minimize wear on the trailer.

Tire size and rating

Tire size and rating of the semi-trailer always depend on the weight that the specific semi-trailer can carry.

Larger Tires: Larger tires generally have a higher load rating, allowing them to carry more weight. For example, tires with a higher load index are capable of supporting larger and heavier loads without compromising the integrity of the tire. This is particularly important for trailers carrying bulk goods or heavy equipment that require more stability and strength.

Tire Rating: Each tire has a load rating, typically expressed in pounds or kilograms, which indicates the maximum weight the tire can safely support. For semi-trailers, selecting tires with the appropriate load rating for the trailer’s weight capacity is essential to prevent tire failure.

Choosing the right tire size and rating ensures that the trailer can handle its maximum weight capacity, minimizing the risk of tire blowouts and ensuring safer transport.

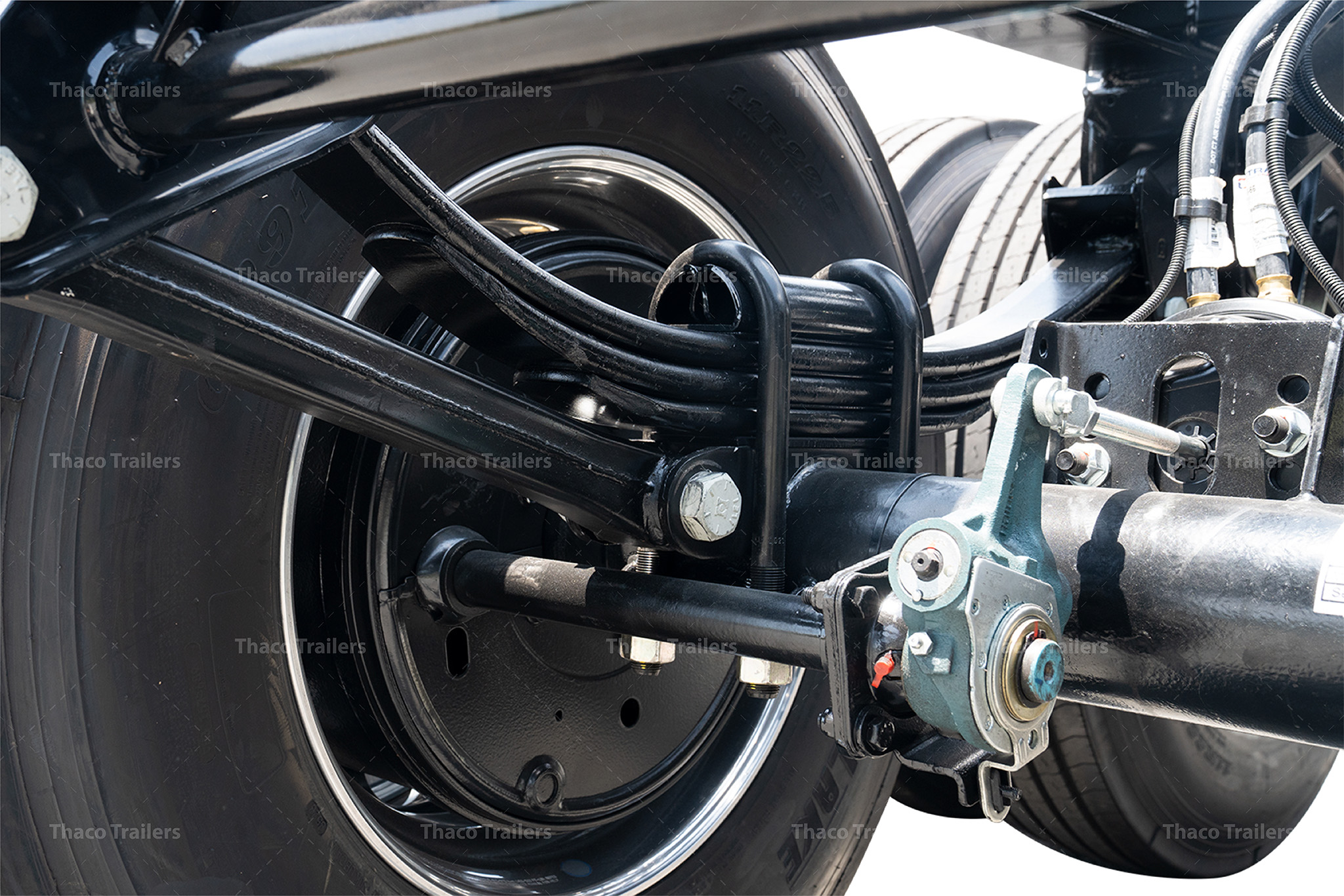

Suspension system

The suspension system of a semi-trailer plays a critical role in determining how much weight it can carry while maintaining stability and ride comfort. Different suspension designs have varying capabilities to support heavy loads and provide stability on the road.

Leaf Spring Suspension: Traditional leaf spring suspension is valued for its strength and reliability, utilizing stacked steel plates to absorb road shocks and evenly distribute weight. While highly durable and well-suited for moderate to heavy loads, it delivers a stiffer ride, which may reduce comfort for sensitive or fragile cargo.

Air Ride Suspension: Air ride suspension systems utilize air bags to absorb shocks, delivering a smoother, more controlled ride for both the trailer and its cargo. Especially advantageous for transporting delicate or fragile goods, this system enhances load stability and minimizes vibration. Additionally, air ride suspension supports heavier loads more efficiently by evenly distributing weight, reducing stress on the trailer and improving overall handling.

Weight capacity calculation method for semi-trailers

How semi-trailer weight capacity is calculated

To calculate the maximum cargo weight a semi-trailer can carry, you need to understand two key factors: Gross Vehicle Weight Rating (GVWR) and Tare Weight.

Gross Vehicle Weight Rating (GVWR): The maximum permissible weight of a fully loaded trailer, including cargo, fuel, and accessories. It is manufactured by the manufacturer and indicates the maximum allowable load including cargo that the trailer has or can have without violating the norms of safety.

Tare Weight: The trailer’s weight when empty, including structural components and fixed equipment.

To determine the maximum cargo weight, you use the following formula:

Maximum Cargo Weight = Gross Vehicle Weight Rating – Tare weight

For example, let’s consider a semi-trailer with the following specifications:

GVWR: 80,000 pounds is the maximum of the total mass of the vehicle including the cargo it may carry.

Tare Weight: 15,000 pounds (the weight of the trailer when empty)

Using the formula:

Maximum Cargo Weight = 80,000 pounds – 15,000 pounds = 65,000 pounds

In this example, the semi-trailer can legally carry 65,000 pounds of cargo. It is essential for operators to ensure that the total weight, including the cargo, does not exceed the GVWR to maintain safety and comply with legal regulations.

Key considerations in weight capacity calculation

Accuracy of Tare Weight:

Precisely measuring the tare weight is critical for ensuring safety and legal compliance. Overestimating the tare weight can result in underutilized capacity, reducing operational efficiency. On the other hand, underestimating the tare weight may cause legal violations, increased wear and tear on the trailer, and potential safety hazards.

Regulatory Compliance:

Weight regulations differ across regions, making it essential for operators to understand and adhere to the specific legal GVWR for their intended routes. Failure to comply with these limits can result in fines, operational delays, and compromised safety on the road. Consulting local guidelines and using tools such as weigh stations or on-board scales can help ensure compliance.

Choosing the right semi trailer weight capacity for you

To select the right semi-trailer weight capacity, it’s essential to carefully evaluate your transportation needs and legal requirements.

Typical Cargo Load: The first step that should be taken is finding out the average weight of the cargo to be transported. If your deliveries are for a variety of different businesses, in all sorts of shapes and sizes, select the trailer that will carry the heaviest loads without stressing the trailer or the towing vehicle.

Type of Goods: Look at the kind of goods that will be conveyed because some products are sensitive to environmental conditions. Perishable goods, especially, are likely going to need extra accessories or enclosures that may affect the Scope of the trailer.

Regional Regulations: Weight limits and regulations vary by jurisdiction. Ensure the trailer you choose complies with the Gross Vehicle

Weight Rating (GVWR) restrictions for the roads and regions you operate in. Failing to adhere to these rules can result in fines or damage to infrastructure.

Material and Construction: If the trailer is manufactured from materials such as light alloys it may be possible to carry more payload, whereas steel framed bodies are much more robust and ideal for heavy use. Select the material that has close corresponding to your operations management priorities.

Discover Thaco Trailers’ heavy-duty semi-trailers, engineered for superior performance and efficiency

Thaco Trailers offers a wide variety of heavy-duty semi-trailers engineered to meet the diverse and demanding needs of the transportation industry. Beyond exceptional performance and efficiency, our trailers are fully customizable, allowing you to tailor every aspect to suit your specific operational requirements. Constructed with lightweight yet high-strength materials, our semi-trailers optimize payload capacity while reducing fuel consumption and operational costs. This approach ensures powerful operation, stability, and durability over the long term, even under challenging conditions.

Thaco Trailers’ products are built to meet both local standards and the stringent demands of the North American market, as well as international specifications. Our trailers are certified with ISO 9001:2015 and ISO 14001:2015, ensuring top-quality manufacturing and environmental management. Additionally, they comply with key traffic and safety regulations set by recognized authorities such as DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA, guaranteeing safety, reliability, and legal compliance.

Explore Thaco Trailers’ heavy-duty solutions today and let us help you design the ideal trailer for your business. Contact us now for personalized consultations or visit our website to learn more about our tailored offerings!

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn