EXPLORING THE DIFFERENT TYPES OF TRAILER LANDING GEAR

Trailer landing gear plays a crucial role in the stability and safety of a semi-trailer when it’s disconnected from the tractor. As a leading manufacturer of high-quality semi-trailers, Thaco Trailers understands the importance of robust and reliable landing gear in ensuring operational efficiency and safety for our customers.

What is trailer landing gear?

The trailer landing gear is a mechanical device that is intended to support the front of a semi-trailer when detached from the towing vehicle. This system is critical to trailer safe positioning and storage when the trailer is parked and stowed.

The landing gear is a critical component of a semi-trailer, ensuring stability and safety when detached from the truck. It maintains the trailer’s stability and balance, ensuring smoother and more efficient loading and unloading. Additionally, the landing gear helps distribute the trailer’s load evenly, preventing damage to the frame. It also plays a key role in aerodynamics and operational efficiency, allowing for secure, quick coupling and uncoupling with a tractor whenever needed, ensuring a smooth transition when the truck arrives for transport.

Key components of landing gear

Landing gear foot

The landing gear foot, also known as the landing gear shoe or pad, is the bottom-most part of the landing gear that makes direct contact with the ground. It is developed to share the load of the trailer over the road base evenly and is durable on various road surfaces.

Landing gear crank

The landing gear crank is a manual mechanism used to extend or retract the landing gear. Typically located on the left side of the trailer, it allows the operator to raise or lower the front of the trailer when coupling or uncoupling it from the tractor. Turning the crank extends the landing gear to support the trailer when detached or retracts it for clearance during transport, ensuring stability and proper operation

Landing gear transmission rod

The transmission rod links the crank handle with the box inside the landing gear legs. It translates the rotational motion from the crank to the internal gears and subsequently lifts or lowers the landing gear.

Landing gear mounting plate

The mounting plate serves as a strong foundation that secures the landing gear assembly to the trailer frame. Designed to withstand operational forces, it ensures the landing gear remains firmly attached while supporting the trailer’s weight.

>> Read more: Understanding Chassis and Trailers: A Comprehensive Guide

Types of trailer landing gear

Hand-driven landing gears

Single-acting landing gear (Two-side operation landing gear)

This type of landing gear requires operation from both sides of the trailer. The operator has to crank each landing gear leg separately, a time-consuming procedure, but it ensures high-level accuracy on non-level terrain.

Linkage landing gear (One-side operation)

A linkage landing gear system allows operation from one side of the trailer. A connecting rod links the crank to both landing gear legs, ensuring they move simultaneously when the crank is rotated. This design improves efficiency by reducing effort and saving time during deployment and retraction.

Hydraulic landing gear

Hydraulic landing gear devices drive the landing gear leg up and down with hydraulic power. These systems are generally faster than manual and require less physical labor. They are commonly found on tow trailers which are heavier, or in situations where fast connection and disconnection are required.

Pneumatic landing gear

Pneumatic landing gear systems use compressed air to operate. They are analogous to hydraulic systems in terms of user-friendliness and speed, but instead of using the trailer air supply. These are relatively easy to be found on trailers with air brakes equipped because they get the same air supply system.

>>Read more: Understanding tandem dolly: key features and benefits

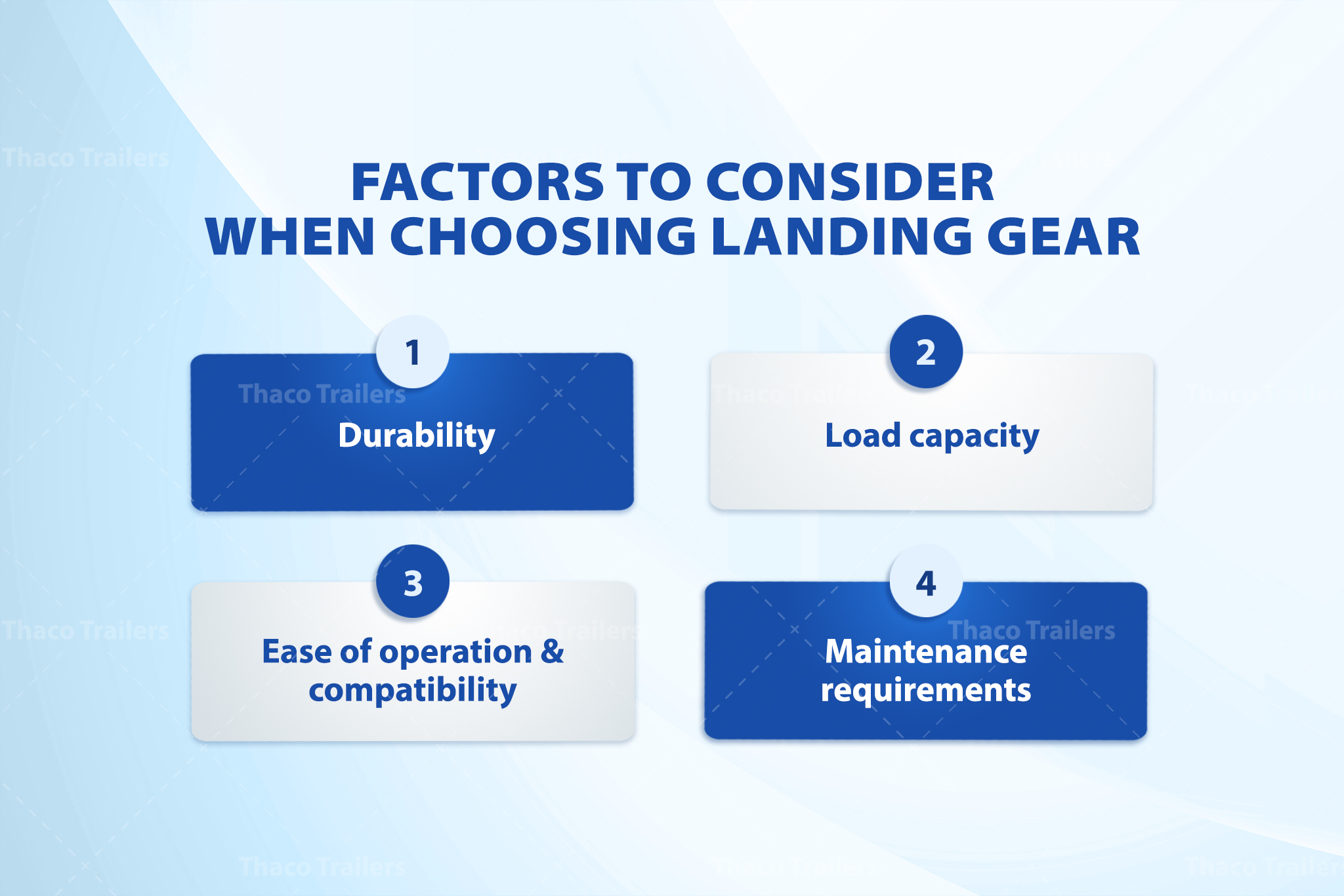

Factors to consider when choosing landing gear

Durability

Durability is crucial when selecting landing gear. Equipment should be robust enough for regular use, under diverse weather and possible impact conditions. Seek components high-strength manufactured from good materials, e.g., steel, with corrosion-resistant coatings. Consider the manufacturer’s reputation and any warranties offered.

Load capacity

The landing gear must be capable of supporting the weight of the fully loaded trailer when it’s not connected to a tractor. Ensure that the chosen landing gear has a load capacity that exceeds the maximum weight of your trailer to provide a safety margin.

Ease of operation & compatibility

Consider how easily the landing gear can be operated, especially if it will be used frequently. In the case of manually actuated systems, verify if the gear ratio offers sufficient mechanical advantage to make lifting easy. For powered systems, ensure they’re compatible with your trailer’s existing power sources.

Maintenance requirements

A simple, low-maintenance landing gear system is a cost-effective choice in the long run. Look for models with sealed bearings and self-lubricating components for durability. Easy access to replacement parts and straightforward maintenance procedures are also important. Some advanced systems even feature diagnostic capabilities to alert operators to potential issues.

Budget

While adhering to a budget is important, it’s crucial to remember that landing gear is a critical safety component of your trailer. When making your decision, consider not just the initial cost, but also the long-term durability and performance of the equipment. In some cases, upgrading to a more durable system may result in reduced overall lifetime trailer costs through less maintenance, and replacement requirements.

>> Read more: What is an intermodal chassis in logistics?

Maintenance tips for trailer landing gear

Proper lubrication of moving parts

Proper lubrication is crucial for ensuring optimal performance and longevity of landing gear, as it significantly enhances functionality and resistance to wear. Lubricate all moving surfaces, such as gears, bearings, and slides. Use a high-quality, heavy-duty grease that can withstand high pressures and temperatures. Make sure grease fittings are open and effective and use the lubrication schedule specified by the manufacturers.

Cleaning to prevent corrosion and replacing promptly

Maintain clean the landing gear so that it does not corrode and collect debris. Rinse the gear with soap and water regularly, especially cleaning the areas where dirt and grime settle. Check for signs of rust or wear, and respond accordingly. When you detect gross corrosion/damage, it is recommended to replace damaged parts as soon as possible to prevent further degradation and unsafe operation.

Checking fasteners and connections

Periodically inspect all bolts, nuts, and fasteners to ensure they remain secure. Vibrations during travel can cause them to loosen over time. Pay special attention to the mounting bolts that attach the landing gear to the aluminum trailer frame. Additionally, check for any signs of wear or damage at the landing gear connection points to maintain safety and stability.

Testing functionality regularly

Perform regular functional tests of the landing gear. This includes full landing gear leg extension and retraction, and smooth function check as well as sound inspection, and sounds of anything abnormal. For powered designs, test all controls and verify the correct response. When you experience problems such as binding, overplaying, or askew movement, immediately take care of them.

Adhering to manufacturer guidelines

Never deviate from the maintenance schedule and procedures provided by the manufacturer. These guidelines are specific to your landing gear model and provide the best practices for maintaining optimal performance. They may also contain advice on how to schedule inspection intervals, where to lubricate parts, and when parts need to be replaced.

Enhance your fleet with Thaco Trailers’ semi-trailers, equipped with superior durability and efficient landing gear

Thaco Trailers delivers high-quality, high-capacity semi-trailers engineered to meet the demands of the transportation industry. Built with high-strength materials and advanced technology, our trailers ensure exceptional durability, lightweight construction, and superior load capacity, making them adaptable to diverse market demands. Equipped with premium landing gear, they provide seamless coupling, secure support, and smooth loading and unloading—reducing downtime and maximizing productivity.

With a strong presence across North America, Australia, Japan, South Korea, and Myanmar, Thaco Trailers offers customized solutions tailored to industry needs. Our products comply with key North American standards (DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, TTMA), ensuring regulatory compliance and operational reliability.

Backed by comprehensive after-sales support, Thaco Trailers is committed to your fleet’s long-term efficiency. Contact us today to discover the best semi-trailer solutions for your business!

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn