FIBER LASER CUTTING MACHINE

Thickness: 25 mm

Cutting size: 12.300×2.000 mm

Quantity: 09 machines

The first step is design and simulation to calculate the overview and details of the product.

Optimized the endurance calculation process and increased the accuracy.

Design and optimize production.

Includes the following stages:

Thickness: 25 mm

Cutting size: 12.300×2.000 mm

Quantity: 09 machines

Cutting size: 15 – 155 mm; Ø20 – 220 mm

Thickness: 10 mm (steel); 5 mm (stainless steel)

Dimension: 6.000×4.100×5.000 mm

Load: 10.000 kg

Max material: 15.000 x 8.925 x 11.078 mm

Max load: 5.000 kg

Max material: 17.000 x 1.600 x 3700 mm

Salt mist resistance: 1.000 hours

Capacity: 37.500 sets/years

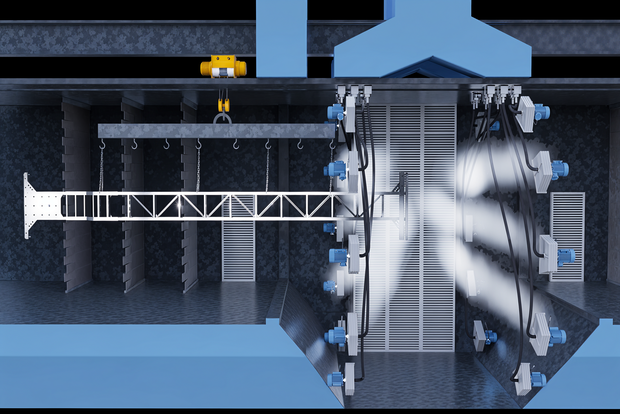

Dimension: 20.900×9.200×7.140 mm

Lifting load: 4.000 kg

Capacity: 19.000 products/year