HOW TO CHOOSE THE RIGHT FIFTH WHEEL COUPLING FOR YOUR TRAILER?

Choosing the right fifth wheel coupling for the trailer is key to ensuring safe and stable towing. With many coupling options for trailers available, understanding the features of each type will help you make the best choice. Thaco Trailers will provide useful information about fifth wheel coupling to help you select the right type.

What is a fifth wheel coupling?

Fifth wheel couplings play significant roles in freight transport as they connect a semi-trailer to a tractor. They not only support the front weight of the trailer but also act as a pivot point, allowing smooth movement and ensuring safety, stability on various road types. Furthermore, these couplings also assist in load sharing, enhance the turning capability and ease in logistic maneuvers.

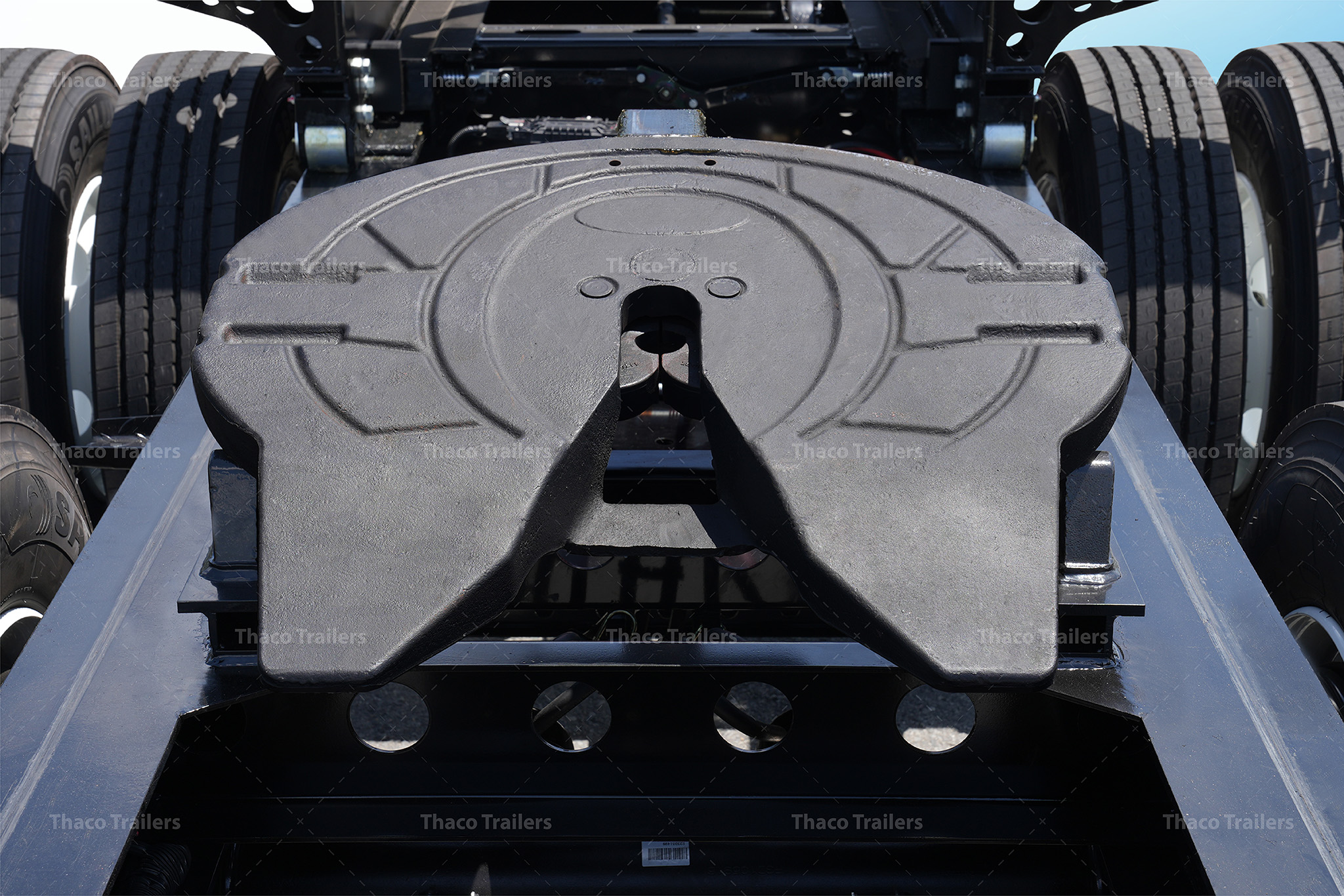

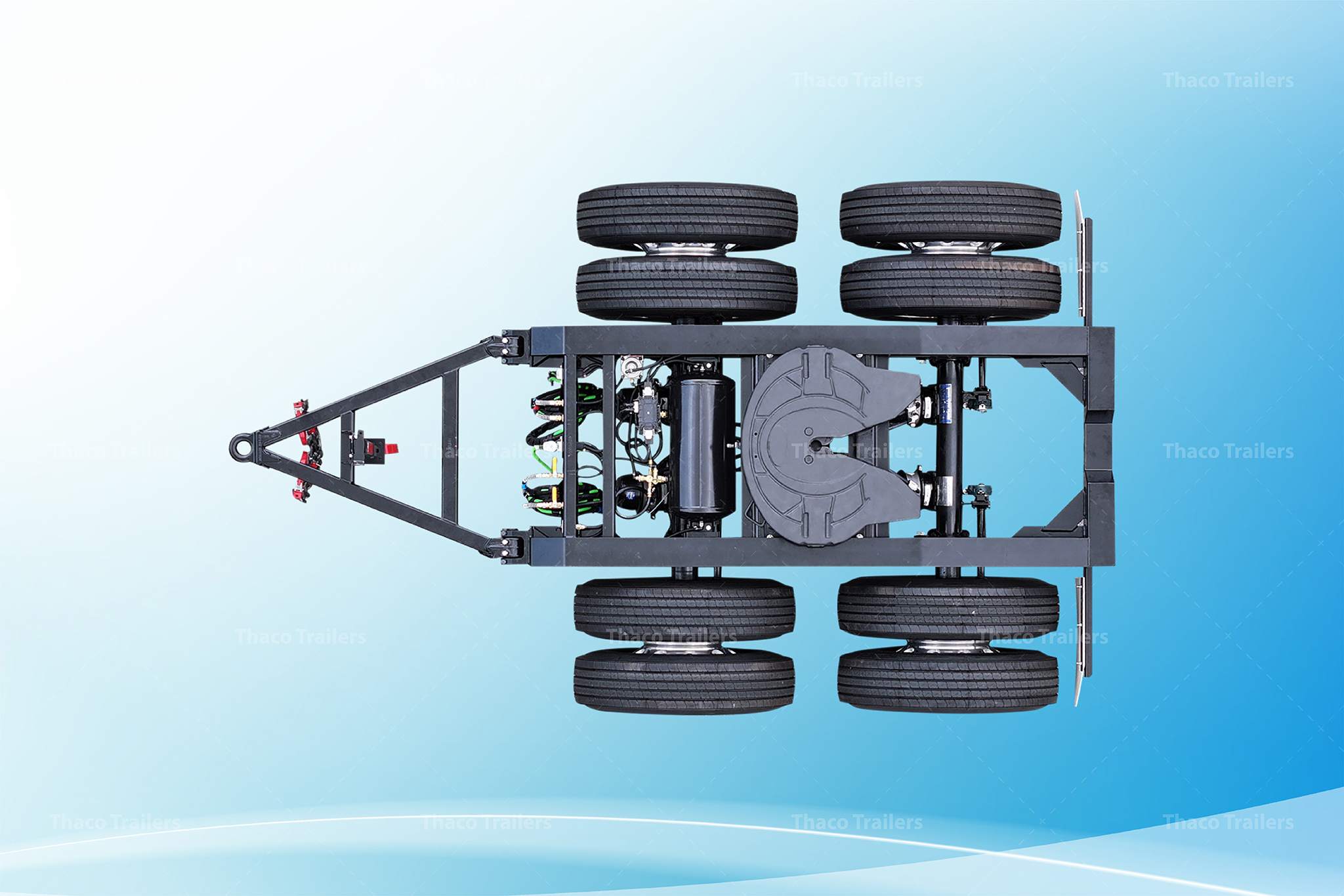

The fifth-wheel coupling system connects the tractor unit to the trailer through key parts. The flat, circular fifth wheel plate holds the trailer’s kingpin, which is a steel pin on the trailer’s underside.

This pin locks into the plate, while a locking mechanism keeps the kingpin securely in position, ensuring the trailer remains safely attached for smooth handling and secure transport.

>> Read more: Understanding Tandem Dolly: Key Features and Benefits

Key Components of a Fifth Wheel Coupling

Top Plate

As the largest component of the fifth wheel, the top plate is a horseshoe-shaped base that secures the coupling parts and supports the trailer’s vertical load, ensuring overall system stability and strength.

Release Handle

This unique part, found only in JOST fifth wheels, makes the process of coupling and uncoupling easier for operators. The release handle facilitates smooth operation and acts as a secondary locking mechanism. Its design offers a clear visual confirmation that the coupling is properly secured, eliminating uncertainty and ensuring safety during transit.

Lever

Though smaller in size, the lever is vital for connecting the release handle to the lock bar. It works in tandem with the other components to move the lock bar into place, locking the mechanism securely across the cushion ring and ensuring the trailer and tractor are firmly connected.

Lock Jaw

Shaped like a “C,” the lock jaw wraps around the kingpin, locking it into place. It is directly linked to the lever and release handle, playing the critical role of securing the tractor and trailer together. This component is essential for keeping the coupling in place during transport.

Lock Bar

The lock bar reinforces the lock jaw by sliding across the cushion ring opening to secure the kingpin. When engaged, it holds the lock jaw in place and ensures the trailer is firmly attached to the tractor, providing additional support for the trailer’s drawbar load during movement.

>> Read more: The advantages of using air ride trailers in transportation

Types of fifth wheel couplings for trailers

Sliding fifth wheel

A sliding fifth wheel is a versatile coupler that moves along the tractor’s frame, allowing precise weight distribution between the tractor and trailer. By adjusting its position, operators can better manage the load on the front (steer) axle. Ideal for varying trailer types and load weights, sliding fifth wheels enhance flexibility and optimize payload capacity.

Key features:

- Adjustable weight distribution to optimize load management

- Increases flexibility for customers with varying loads

Fixed fifth wheel

Stationary fifth wheels, also called fixed fifth wheels, are the traditional couplers, mounted in a fixed position on the tractor’s frame. These are best for fleets where trailer types, load weights, and vehicle lengths remain constant. Stationary fifth wheels are typically lighter and simpler in design.

Key features:

- Lighter and simpler design compared to sliding fifth wheels

- Reduces maintenance needs

- Improves payload capacity, helping to reduce operating costs and increase profitability

>> Read more: What is a genset chassis? Application and How it works – Thaco Trailers

Pros and cons of fifth wheel coupling

Pros

Stability and Control: Fifth-wheel coupling offers superior stability for towing heavy loads. The pivot point directly above the rear axle helps distribute the weight more evenly, reducing trailer sway and improving control, especially during high-speed travel or sudden stops.

Higher Towing Capacity: With its design, the fifth-wheel coupling can handle much larger loads compared to traditional hitch systems. This allows for greater towing capacity, making it ideal for large trailers, RVs, and commercial freight hauling.

Easier Maneuverability: The positioning of the pivot point provides improved maneuverability, especially when turning tight corners or navigating narrow spaces. It’s a great advantage for drivers working in busy areas, such as loading docks or crowded streets.

Less Weight on the Rear: Fifth-wheel coupling helps distribute the weight across the vehicle, reducing stress on the rear suspension. This leads to improved handling, less wear on the vehicle, and enhanced overall vehicle longevity.

Quick Connect/Disconnect: With some practice, the fifth-wheel coupling system allows for fast and easy connection and disconnection. This is particularly beneficial in situations where time efficiency is important, such as during loading and unloading.

Cons

Installation Complexity: Installing a fifth-wheel hitch will need the help of a professional with a general understanding of the things to do, and the tools to deploy. The inexperienced can find it a bit rigorous, and this can result in more time being taken, and hence the potential to tend to make mistakes when making the settings.

Cost: High-quality components, especially the fifth wheel coupling system, require a significant initial investment. This may be less cost-effective for users with infrequent or low-strain towing needs.

>> Read more: Thaco Trailers: Top Chassis Manufacturer & OEM Component Manufacturer

Install and maintain a fifth-wheel coupling

Step-by-step installation guide

Step 1: To install the fifth-wheel coupling, use 12 M16 bolts with a strength class of no less than 8.8, ideally M16 x 1.5 with a strength class of 10.9. These bolts should be positioned symmetrically around the fifth-wheel coupling on the mounting plate.

Step 2: The landing gear must contact the mounting plate over the same width as the landing gear. For undulating mounting plates, ensure that there is contact and support in the middle area of the landing gear.

Step 3: Next, secure the fifth-wheel coupling both longitudinally and laterally by welding a thrust plate, ensuring there is no play between the thrust plate and the landing gear or the fifth-wheel coupling. The welding methods should be in accordance with what the manufacturer of the vehicle and the mounting plate recommends. If the fifth-wheel coupling and mounting plate are securely fastened and maintained, there is no need for thrust plates.

Step 4: The bolt connections should be designed to allow for the prescribed tightening torque values or pre-stressing force. The general rule is that the coating thickness of the paint around the securing area of the bolts should not exceed 120 mm.

Step 5: Some of the bolt connections should be tight enough to prevent them from becoming loose during the operation of the equipment.

Step 6: The Last step is to check that the fifth-wheel coupling is to shift along a plane parallel to the direction of travel, and does not come into contact with any part of the chassis to guarantee safe and efficient operation.

>> Read more: Exploring Lightweight Chassis for Modern Logistics

5 Tips for fifth wheels maintenance

Clean all components

Regular cleaning of all fifth-wheel components is essential for ensuring smooth operation and reliable performance. Over time, dirt, debris, and rust can accumulate, leading to friction and potential damage. To prevent this, use a suitable cleaning solution and tools to remove any buildup from the fifth wheel and its surrounding parts.

Check the operation of the locking mechanism

The locking mechanism plays a crucial role in securely attaching the trailer to the truck. Regular inspections are necessary to ensure smooth operation and a secure lock. Check for signs of wear or damage, and verify that the mechanism latches and releases properly to enable safe coupling and uncoupling.

Check the fastener torque, bolts, and other parts

Fasteners, bolts, and other critical parts must be inspected to ensure they are properly tightened and secure. Over time, bolts may loosen due to vibration and wear, potentially compromising the stability and safety of the fifth wheel. Regularly check the torque of all fasteners to maintain the integrity of the connection between the truck and trailer.

Use a water-resistant lithium-base grease to grease the trailer

Lubricating the fifth wheel with a water-resistant lithium-based grease helps reduce friction and prevents wear on moving parts. This type of grease provides durability and protection against moisture, preventing rust and ensuring smooth operation even in challenging weather conditions. Apply grease as needed to all contact points to maintain optimal performance.

Check your fifth wheel slide adjustments

The fifth wheel slide allows for adjusting the position of the coupling to ensure the right balance and weight distribution. Regularly check and adjust the slide to ensure it is functioning correctly. This will help optimize the turning radius and overall stability of the truck and trailer, ensuring safe and efficient operation.

When should you replace your fifth wheel coupling?

Gapping between the fifth wheel and the underside of the trailer: If you find there is a significant gap between the fifth wheel and the trailer’s floor, it may also mean the coupling is no longer seated properly. This could result in instability and unsafe conditions every time one is driving. If the space is regular and increases, this is time to change the fifth wheel coupling.

The locking pin sliding or not engaging fully: If the locking pin does not slide smoothly or fails to engage fully, it can compromise the security of the trailer attachment. This issue can prevent proper coupling and uncoupling, posing safety risks. A malfunctioning locking pin should prompt an immediate replacement of the fifth wheel coupling.

General visible signs of excessive wearing on and around the fifth wheel: Look for visible signs of excessive wear on and around the fifth wheel, such as cracks, deep grooves, or unusual thinning of metal parts. These signs indicate that the fifth wheel coupling has been subjected to significant stress and is no longer functioning at its best. If the wear is substantial, replacing the coupling is necessary to avoid further damage or failure.

>> Read more: What is a curtainside trailer? An In-Depth Overview

Thaco Trailers’ semi-trailers – Engineered for excellence with top-tier fifth-wheel couplings

Thaco Trailers’ semi-trailers are engineered for excellence, equipped with top-tier fifth-wheel couplings that ensure superior stability and strength. These trailers are designed with high-quality components to provide optimal performance, durability, and cost-efficiency across various operational conditions. Specially one of the added advantages businesses will find when ordering from Thaco Trailers is the ability to trailer their customization.

With Southeast Asia’s largest manufacturing facility, Thaco Trailers produces flatbed semi-trailers of exceptionally high quality that fully conform to DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA standards. Our products are built from premium materials sourced from global suppliers, ensuring outstanding durability, performance, and reliability for demanding transportation needs. This commitment to quality has established Thaco Trailers as a trusted brand in the industry.

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn