HOW MANY TYPES OF SKELETON TRAILERS? 20/40/53FT

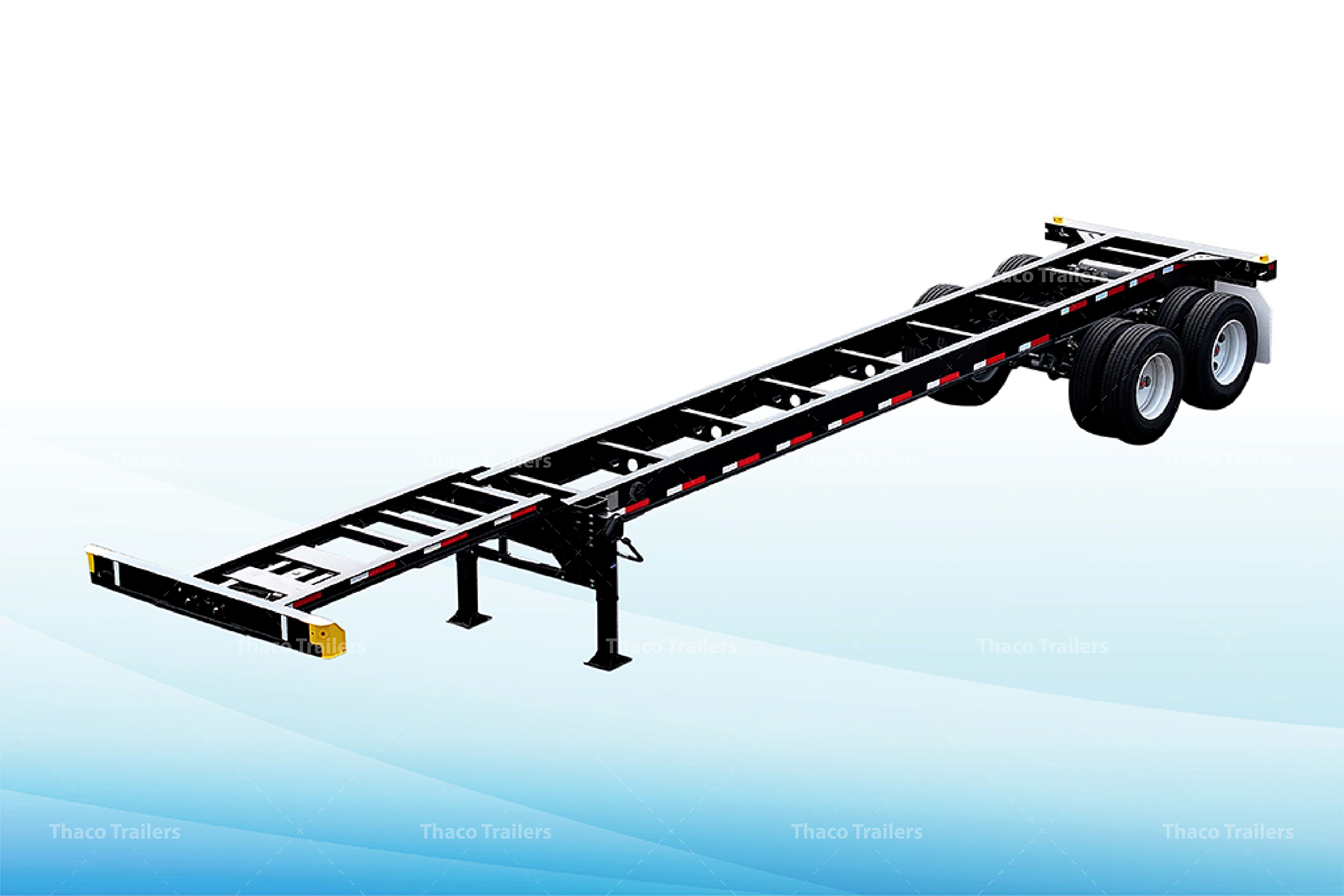

Skeleton trailers, also known as skeletal trailers, are specialized vehicles designed to transport containers efficiently within the logistics industry. Their lightweight yet durable structure ensures secure and stable movement of containers of various sizes. Playing a crucial role in global supply chains, skeleton trailers from Thaco Trailers facilitate the smooth movement of goods from one place to another.

1. What is a skeleton trailer?

Skeleton trailers, also known as skeletal trailers, are essential vehicles in the transportation industry for carrying containers of various sizes. The design features a low tare weight, essentially with a framework structure, popularly known as a “skeleton” comprising beams of steel with no floor or side covering, hence allowing them to facilitate smooth transfers of containers. This lightweight structure is specifically built to securely carry standardized containers, typically 20ft, 40ft, or 53ft in length.

2. How does the skeleton trailer work?

Skeleton trailers work by providing a stable platform for containers, which are locked onto the trailer’s frame using twist locks. Once the container is properly positioned, the twist locks on the trailer are manually or automatically engaged to rotate into place and fit into the container’s corner castings. This design ensures that the containers are securely attached, providing stability even on uneven roads or during sharp turns.

Upon reaching the destination, the twist locks are disengaged, allowing the container to be lifted off the trailer and placed on the ground, a storage area, or directly onto another mode of transport.

Adjustable locking mechanisms of skeleton trailers allow them to accommodate containers of various lengths, providing flexibility in transportation. The trailer’s compatibility with different truck types enhances its versatility for diverse hauling needs.

3. The outstanding advantages of skeleton trailers

Skeleton trailers offer several advantages that make them a preferred choice in industries that rely heavily on containerized cargo, such as shipping, logistics, and intermodal transport.

- Cost-effective: The simple design applied to skeleton trailers makes them cheaper to purchase and maintain than any other type of trailer. A streamlined structure reduces fuel expenses and operating costs, especially for long-distance travel. Thus, your business will find container transport more economically efficient.

- Versatile applications: Skeleton trailers are suitable for transporting common container sizes like 20ft, 40ft, and 53ft containers. This versatility enables them to offer wide application in logistics and shipment services, including port-to-rail or port-to-road transportation.

- Durability: Constructed with high-strength steel sourced from top-tier, reputable suppliers, these trailers ensure exceptional quality and durability. This results in reduced maintenance needs, greater reliability, and consistent performance, even under harsh operating conditions.

- Flexible adjustments: With an open-frame design, skeleton trailers support easy loading and unloading of diverse cargo types, including oversized items and containers of varying sizes. This adaptability eliminates the need for specialized equipment and enhances fuel efficiency and payload capacity, making them ideal for diverse logistics operations.

- Lower maintenance and repair costs: Due to their simplified open-frame design, skeleton trailers incur lower maintenance and repair costs. Fewer components are vulnerable to wear and damage, reducing the likelihood of mechanical issues. The minimalist structure also makes inspections and repairs easier, leading to reduced labor and downtime. The absence of enclosed panels and complex systems further decreases exposure to environmental factors, lowering the frequency of maintenance.

- Stability while towing: One of the standout advantages of skeleton trailers is their stability while towing. Their lightweight structure and low center of gravity reduce the risk of swaying or tipping, even when carrying heavy or unevenly distributed cargo. Enhanced maneuverability in tight urban spaces and improved handling ensure greater safety and efficiency during transport.

4. Common types of skeleton trailers

Skeleton trailers come in a variety of types, each type is designed to meet specific transport needs, cargo requirements and categorized based on its structure and size. Understanding the common types of skeleton trailers helps businesses choose the most suitable option for efficient and secure transportation.

4.1 Structure

- The skeleton trailer more commonly referred to as a container chassis, is especially designed for the transportation of shipping containers. It consists of a minimal frame with twist locks that accommodate a container in various lengths such as 20 feet, 40 feet, 45 feet, 48 feet, and 53 feet. Its rigid structure ensures maximum reliability and longevity with minimal maintenance costs.

- The gooseneck skeletal trailer features a drop frame that allows for a lower center of gravity that increases stability and becomes quite useful in the case of a tall container. A gooseneck design provides much better height management compared to a standard skeletal trailer, which is necessary to meet the demand for federal transportation by businesses due to different height regulations in various states.

- The extendable trailer is a specialized type of skeleton trailer designed with a telescopic frame, allowing it to adjust its length to accommodate various container sizes, including 20-foot, 30-foot, 40-foot, and 45-foot units. This adaptability enhances operational flexibility, enabling efficient transport of different cargo dimensions without the need for multiple trailers. The extendable feature also optimizes load distribution and stability, contributing to safer and more efficient hauling operations.

- The slider trailer features a movable chassis that can adjust to accommodate various container sizes, including 20-foot, 30-foot, 40-foot, and 45-foot units. This design enhances operational flexibility by allowing the trailer to extend or retract its length, facilitating the transport of different container dimensions without the need for multiple trailers. Additionally, the sliding mechanism aids in optimizing load distribution and stability, contributing to safer and more efficient hauling operations.

- The tipper skeleton semi-trailer features a hydraulic tipping mechanism for tilting, allowing efficient unloading of loose cargo such as sand, gravel, or grains. This makes it ideal for construction and agricultural applications. When fitted with a dump bed, it becomes a specialized trailer. Without one, it functions as a general chassis, offering versatility and efficiency in bulk cargo handling.

4.2 Size

Skeleton trailers are available in various sizes to accommodate different types of cargo, primarily focusing on container transportation. Thaco Trailers will introduce some common sizes of skeleton trailers, highlighting their specifications and applications to meet the diverse needs of industries like logistics and shipping.

- The 20ft skeleton trailer is a robust-framed skeleton designed to carry a 20ft intermodal shipping container. Being a 20ft trailer, it is considerably smaller in size, and therefore easier to handle in a tight space, such as ports, warehouses, and even areas in the heart of towns.

- The 40ft skeleton trailer is engineered to transport ISO-standard containers, accommodating either two 20ft containers or one 40ft container. Constructed from high-strength materials like Q345 or SM490 steel, it ensures exceptional durability and offers a payload capacity often exceeding 30 tons. Key features include multiple twist locks for secure container fastening, dual or tri-axle configurations for heavy loads, and advanced braking systems for enhanced safety. Widely used in intermodal transport, the 40ft skeleton trailer facilitates the seamless transfer of goods across ships, trucks, and trains.

- The 53ft skeleton trailer is designed for transporting 53-foot shipping containers, commonly used in intermodal transportation. Its open, skeletal frame minimizes weight while providing the strength to support large containers, making it ideal for efficient loading and unloading, especially with cranes or forklifts. The trailer’s twist-lock mechanisms securely fasten containers, and its versatility allows it to accommodate different container sizes, making it a cost-effective solution for long-distance logistics across highways, railways, and ports.

5. Thaco Trailers skeleton trailers for sale in North America

Thaco Trailers offers skeleton trailers designed to meet the highest standards of quality, durability, and performance, making them a top choice for transport providers in North America. Our trailers are built using premium materials and components that strictly meet North American standards, sourced from globally renowned suppliers such as Hyundai Steel, Hoa Phat Steel, POSCO, AXN, SAF Holland, TECTRAN, and YORK.

What sets Thaco Trailers apart is our comprehensive quality control process, which includes rigorous testing of brake systems, electrical components, chassis strength, and its capacity under real-world conditions such as gravel roads, rough terrains, and tight circular tracks and meets the strict standards of North American, including DOT, AAR, ANSI, TOFC, F(C)MVSS, SAE, and TTMA. Our trailers are equipped with safety features such as Anti-Lock Brake System, Anti-Roll Stability System, Tire Pressure Monitoring System and Automotive Tire Inflation System to mitigate rollover risks in trailers by continuously adapting to the vehicle’s speed, load, and driving environment to maintain balance.

With an annual production capacity of 30,000 units and a dedicated focus on research and development, we provide innovative, customized trailer solutions tailored to the unique needs of the North American market. Contact us now to explore our range of skeleton trailers designed to elevate your transport operations.

Contact Information:

- Hotline: (+84) 933 805 707

- Email address: thacosv@thaco.com.vn